Full Bore Vs. Reduced Bore

Share:

It is easy to confuse the many different types of ball valves, and they come in varying shapes and designs, and keeping up with the minute details that set them apart can be hard. This misunderstanding can lead you to buy the wrong valves for your project. Among the many types of ball valves that get confused with each other, full bore and reduced bore ball valves are the most notorious in that regard.

We are going to look at the differences between full bore and reduced bore, their respective functions, how they compare with each other in terms of design and functionality, and the things you have to consider when making a choice between the two. So stick to the end and learn a few helpful tips.

Table of Contents

Full Bore Valves

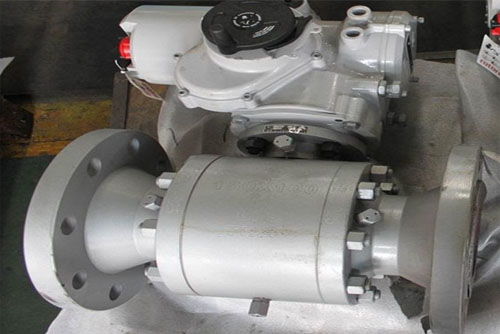

Full Bore Valves

Source: Pinterest

Full bore valves are simply valves that open completely, creating an unobstructed path for gases or liquid being pumped through a tube or pipe. The valve in question is usually smaller than the internal dimensions of the bore of the end connections.

The width of the flow channel in a full bore ball valve is equal all through from the inlet to the outlet, and that diameter size cannot at any point be smaller than the conventional size specifications. The following are the key points that qualify a valve as full bore.

API 6D and API 608 are some of the full bore sizes that are published by one organization with very slight differences regarding their bore size requirements.

Full bore valves range from pressure classes that are limited between 150 to 600, and this includes valve dimensions like API 608 and API 6D. The biggest ones can reach all the way to 2500.

The minimum bore size for a full bore valve should be API 6D.

However, it is important to note that some valve manufacturers do make slight variations depending on the request of the client, who may want something customized to their needs. For this reason, it is easy to come across some full bore valves that are either bigger or smaller than then given standardized limits.

Based on its design, the full bore ball valve is mainly used to transport viscous mediums that are prone to slagging along the pipelines. This is possible due to the low fluid resistance, and this is what makes the movement of heavy materials much easier.

Reduced Bore Valve

Source: Pinterest

This is a ball valve whose opening is much smaller than that of the end connection. In most cases, this opening is never larger than 9mm and is used for smaller pipes that are used to feed materials into tanks and other storage units in most refinery companies.

The internal parts of the reducing ball valve are wider for the flow compared to the path diameter, while the actual diameter of the actual flow path is approximately one specification smaller than the conventional parameters. The following are the key points that qualify a valve as a reduced bore valve.

Most reduced bore holes start from API 6D all the way up to API 608, with some being described as double reduced bore valves.

The existence of a gap in EEMUA 182 for this type of valves that have a rating that’s greater than class 600.

Considering the design of the reducing ball valve, the best application for this type of valve would be in pipelines that convey lighter mediums like gas or materials that are less viscous like water. It has some level of resistance compared to a full bore valve, but this is what makes it perfect for light-medium, as it reduces the pipeline load significantly.

Comparison

Source: Pinterest

When it comes to convenience in terms of use, cost and installation, there are some differences between a full bore and reduced industrial ball valves. These differences can be categorized in the following manner.

Installation: A reduced ball valve has a smaller volume, and this makes installing it much easier as it has fewer requirements and is also way much lighter when compared to the full bore valve, which is 30% heavier and generally has a bigger volume. This makes the reduced ball valve more ideal for reducing the load in the pipelines as well as bringing down the cost of transportation.

Cost: The cost of a reducing ball valve is lower than the price of a full bore ball valve, and this comes down to performance and size. The full bore has the ability to handle bigger tasks without collapsing and is constructed bigger using high-quality materials. Reduced bore valves, on the other hand, are smaller, and although they are also made using quality materials, they cannot handle the same level of work that full bore valves take care of.

Nature of Work: Full bore valves are able to handle highly viscous mediums that would have problems being transported from one point to another if they were handled by other types of valves. This is the kind of valve that you will never miss in an oil refinery plant. Reduced bore valves, on the other hand, are designed for handling lighter mediums like paraffin which can move quickly even when there’s some resistance in the system.

Size: Full bore valves are way bigger than reduced bore valves. This difference can be seen through the size, the volume, and the weight. Full bore valves go into slightly wider tubes and pipes, while reduced bore valves go into smaller ones.

Factors to Consider Before Deciding What to Go For

Source: Pinterest

Before making that all-important decision to choose a full bore or reduced bore ball valve, there are some few factors that should help guide you towards making the right and informed decision. They include the following.

Client Specification: If you are a manufacturer or supplier, then you can only take what the customer wants as they are best placed to know their needs. The best you can do in that situation is to advise them on the materials to be used in the construction once the decision has been reached.

Pressure Drops: Pressure drops are a huge concern for reduced bores, and they can affect how the medium is transmitted from one to another. Any extreme variations will make the whole operation collapse. Full bore, on the other hand, can handle both extremities without flinching.

Utility Services: The ease of maintenance should also guide you in choosing something that will not end up causing you trouble down the road. If you lack the proper manpower to handle regular cleaning due to blockages and other issues, then consider going for a full bore ball valve as it has what it takes to maintain its condition for much longer.

Size of Pipe: The size of the piping system is another factor that is worth considering; full bore valves are designed for bigger pipes that can handle highly viscous mediums, and for this reason, the opening has to be opened wide possible for an uninterruptible flow. Reduce bores, on the other hand, need smaller piping and tubing systems as they handle less heavy medium and are much faster.

Conclusion

The type of valve you choose to go with must come after serious research since any small mistake may derail an entire system, and this could run to huge losses if nothing is rectified. There are many other types of valves in the market like stainless steel globe valve, and covering them all here is impossible. However, if you wish to learn more, then don’t hesitate to check out our website and have all your questions addressed by our team of qualified experts.