Flanged gate control valve, also called the globe control valve, is a type of globe valve that controls the flow of liquid in a pipeline. It is used to slow the flow down, stop the flow completely, or allow the fluid to move freely. Because of its control functions, it is very popular in process control and plumbing industries and is also utilized for special applications such as steam services, cryogenics, and toxic and corrosive processes.

In this blog, we will unravel more information about flanged gate control valves – how they work and how they can benefit you and your industry!

Table of Contents

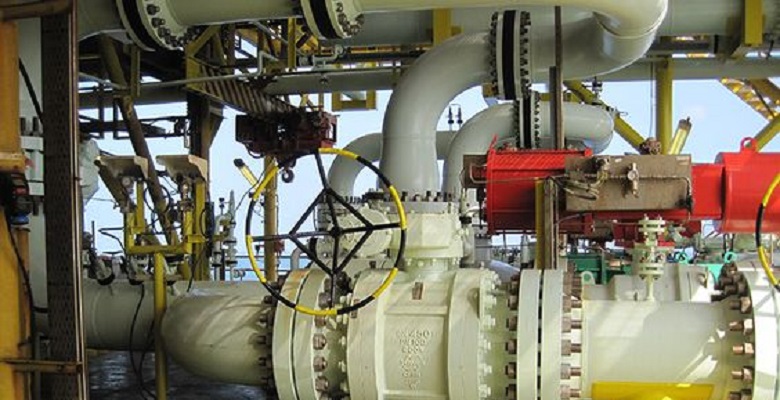

What Is A Flanged Gate Control Valve?

Source: https://www.samsoncontrols.com

Designed primarily for the regulation and control of the flow of liquid, flanged gate control valves have a globular shaped body. This type of valve also has a ring and a flat disk that is inserted into the ring to stop the flow of fluid, which is collectively called the baffle.

Flanged gate control valves are commonly used in systems where leak tightness, safety, and flow control are essential and necessary. Compared to gate valves, leaks are less likely to happen from the globe valve seat since the seat ring and the disk form a right angle contact, creating a tighter seal to seat the disk.

Globe valves can also be used for throttling systems as the graduate change in the space of the disk and seat ring allows the throttling ability of the valve.

How Is A Flanged Gate Control Valve Constructed?

Aside from its distinct globular shape, the components of globe valves, like those of flanged gate control valves, make them highly functional valves in systems requiring flow control.

Knowing the functions of the flanged gate control valve is a must, but understanding its main parts and how they work will help you learn how the fluid circulates and flows around the entire equipment.

Here is a diagram of the components to guide you and help you locate them in a globe valve:

Source: https://valveproducts.net

Body

The body helps in the formation of the mass of the valve, and contains the main pressure structure. The movement of the substance will come in contact with the entire internal parts of the valve as it is regulated and these internal parts is surrounded by the body. The bonnet is purposely linked to the body since it is responsible for the stipulation of the containment of the regulated fluid, slurry, and gas.

Bonnet

The bonnet is connected to the body since it provides closure to avoid leaks as the fluid is being regulated. There are three types of bonnet for globe valves: screw-in, bolted, or union. Each type differs in its application.

For the screw-in bonnet, it is best for applications that need a pressure tight and durable seal. The bolted bonnet is best used for higher and more extensive applications, especially for services that require frequent operation and throttling, while the union bonnet is utilized for applications that requires regular cleaning or inspection.

Plug or Disk

Linked to the stem that is screwed up and down to make adjustments for the control, the plug or disk is a part of the closure member of the valve. It has two forms: the balanced and the unbalanced type.

The unbalanced type is maximized if smaller valves require low pressure drops. On the other hand, the balanced form has holes towards the plugs, allowing an easier mechanism for shut off.

Stem

The stem helps in the transmission of the actuation force since it links the actuator inside the valve. The stem must be able to withstand a large compression force and must have a significant amount of strength to open the valve.

Seat

Can be installed in the area where the body of the valve is located, the seat provides a stable, replaceable, and consistent surface for shut off. Most globe valves have a backseat, a seating arrangement that makes a seal between the bonnet and the stem.

The backseat protects the valve packing from pressure since the disk rests on it when the valve opens. It also helps in reducing the amount of leakage since the disk to seat ring contact forms a right angle, sealing the connection tightly.

HandWheel

The handwheel is used to regulate the valve manually.

How Does A Flanged Gate Control Valve Work?

Source: https://hardhatengineer.com

Interestingly, flanged gate control valves differ from gate valves, since if you open the gate valve slightly, the amount of flow is not proportional to the opening. Also, the velocity of the flow in a gate valve is very high. For flanged gate control valves, you will not encounter this type of problem.

Flanged gate control valves are linearly actuated because as the valve is open, the fluid travels linearly upwards. As the fluid moves away from the port, more and more flow takes place through the valve. To increase or decrease the flow of liquid in a flanged gate control valve, turn the handwheel to rotate the valve’s stem and lower or raise the plug into a valve seat.

As the valve opens or closes, the disk perpendicularly moves to the seat. The disk can close the flow path complete, or be removed from the flow path entirely.

Using the valve to control the fluid flow is done with the help of the baffle. The baffle has two parts: the ring-shaped seat and the flat plug. The fluid’s movement is constrained completely when the plug has been appropriately positioned into the seat. Nevertheless, you can manipulate the baffle depending on the amount of fluid that you would allow to flow as you open or close it.

The amount of flow that goes through the valve is determined by the distance between the plug and seat. When the distance is greater, the amount of flow will be also larger.

Flanged gate control valves are generally installed in low-temperature applications to place the pressure under the disk since the direction of the flow occurs under the plug. When the pressure is on the underside of the disk, it is effectively pushing the disk upwards, making it easier for you to open the valve. Aside from the valve can be opened quickly, the packing is protected and is not exposed to the system pressure.

For high-temperature applications, however, flanged gate control valves are placed to put the pressure above the disk, since the flow must be changed to the opposite direction for the stem to maintain a constant higher temperature. Doing so decreases the possibility of the stem from contracting and lifting the plug off the valve seat. Because when it contracts, the stem will allow the steam to pass through the valve again.

Benefits of Using Flanged Gate Control Valves

Source: http://valveproducts.net

Demonstrates close regulation

A distinct feature of a flanged gate control valve is its close regulation. The relation of the size of the seat opening and the number of turns made in the handwheel of this type of valve are in proportion with each other, achieving close regulation. With this, the manipulation of the flow frequency with connection to the turns in the handwheel can be done easily.

Saves work and time

Globe valves require fewer turns compared to other types of valves like 220v solenoid valve. In addition, the repair of the disk and seat of the cast steel gate valve, just in case they are broken, can be executed easily since you do not have to remove the valve from the pipeline.

Conclusion

SIO Flanged Gate Control Valve boasts on its inclination to deal with both low and high temperature and pressure applications. Its capacity for throttling and smooth fluid regulation and control functions make it an ideal choice in the plumbing and process control industries.

If you are looking for high quality and durable flanged gate control valves or stainless steel flange ball valve, get in touch with us today! SIO is known as one of the steam control valves manufacturers, we provide various quality control valves.