Gate Valves

Products Portfolio

By Type

By Design

By Material

By Actuator

By Industries

- Slurry Valves

- Water Treatment & Wastewater Valves

- Natural Gas Valve

- Chemical&Petrochemical

- Geothermal Energy

- Gas Process & Refinery

- Pulp and Paper Valves

- Mining Valves

Assessories

Gate Valves

SIO manufactures and customizes high-quality gate valves for different applications. These valves are mainly used for stopping and starting fluid flow. They are also used when straight fluid flow is required as well as when minimum restriction of flow is needed. In most applications, these valves are widely open or completely shut.

When the gate valve is completely open, the disk is removed entirely. This will leave an opening for the fluid passing through the gate valve. There will be no obstruction, thus ensuring a low loss of friction. This type of valve is useful in different types of fluid and ensures a steady seal when shut.

You can depend on SIO to make the most efficient gate valves for all your fluid flow needs.

Gate Valve Manufacturer

A gate valve, also known as a sluice valve, is one of the most widely used valves in industrial applications. It is primarily manufactured to control the flow of process fluid. It is equipped with a flat closure component, better known as the gate, that slides into the line to restrict flow.

As a reliable gate valve manufacturer, gate valve produced can cut through slurries and other viscous materials, such as grease, heavy oil, cream, molasses, and more. It is well-suited for liquid applications, such as in oil and gas industries, water and wastewater treatment facilities, pharmaceuticals, and power plants.

A gate valve is available in different sizes to handle different volumes of process flow in SIO. Moreover, it can be made from different types of materials and design features and options.

Ball Valves Features

SIO's valve testing and inspection for their cast stainless steel valve adheres to ANSI B16.34/ API 598.

The end connections of SIO’s forged gate valve are highly versatile and include SW, NPT, RF, BW, Extended tubes.

SIO forged and cast gate valves both come with Outside Screw & Yoke features.

Stainless steel gate valves by SIO have face to face dimensions compatible with ASME/ANSI B16.10.

Why use Gate Valves?

Low Fluid Resistance

Gate valves have a straight shape which allows the fluid to pass through easily without any resistance or blockage. As compared to other types of valves, these offer minimal fluid resistance.

Two Way Flow

Apart from allowing easy blocking and passing through of different kinds of fluid, a major advantage behind using gate valves includes them being bidirectional.

Robust Sealing Performance

While being used for media regulation, gate valves work to effectively shut off the flow without causing any leakage. The on/off mechanism of gate valves is much more convenient than other types.

Standard and Specification of Gate Valve

Before buying a gate valve, it is important that you determine the requirements of your application. This is to ensure that your gate valve is reliable, effective, and has a long lifespan. Here are the important factors to consider so you can choose the proper gate valve manufactured by us that will serve you for a long time:

Integration with Other Parts of the System

A faulty wedge can lead to high abrasion and affect functioning so looking at the design and size is essential for industrial compatibility. For a limited space, small sized gate valves work well but cannot handle high pressure systems like bigger gate valves do.

The Process Flow

SIO’s industrial gate valve needs to be inspected thoroughly so that the material and media compatibility can be worked upon in case errors are seen.

The Operation and Function

Understanding the specific operation and function of the gate valve and the system it will be installed in helps determine which type of material and end connection will be best suited.

The System Temperature

The shut-off function of a gate valve is also useful in managing hot and cold fluids. It is also important that you determine the temperature of the process flow. Various materials are used in the manufacture of gate valves, such as stainless steel, carbon steel, cast steel, carbon steel, and more. Each of these materials is well-suited for specific temperature ranges.

The System Pressure

The shut-off function of a gate valve is designed to endure different pressures of fluid. It is essential that you identify the pressure range that will go through the gate valve. This helps you choose the right size and maximum pressure capacity to handle such working conditions.

Cleaning and Maintenance

Cleaning and maintenance affect gate valve’s performance of the working system. Is the gate valve accessible and can it be cleaned easily? Answering these questions helps you determine whether or not a gate valve is suitable and practical for the entire system.

Common Ball Valve Applications

As a professional gate valve manufacturer, SIO supplies high-quality gate valves that could be used in all high pressure and high temperature.

Gate valve for steam service

Gate valve for gas service

Gate valve for high temperature service

Gate valve for vacuum service

Gate valves for high pressure service

Gate Valve Manufacturing

While manufacturing gate valves, SIO ensures that the conditions are perfect for precise production, even in wholesale. For high temperature gate valves, the manufacturing will require the forging or casting of different metals and alloys as per the client’s request.

Our facilities are equipped to handle the mass-production of gate valves for both industrial and commercial applications. We ship worldwide and will be right there on your doorstep just when you require our service.

What Are the Different Types of Gate Valves?

Gate valves are mainly used to provide tight sealing in a variety of industrial applications. However, there are many types of gate valves that differ in materials, pressure and temperature ratings, valve operator, etc. To provide you better understanding and determine which type of gate valve you need, here are the different categorizations of gate valves:

Gate Valves by Material

Stainless Steel Gate Valve

A stainless steel gate valve is known for its resistance properties towards corrosion and abrasion. These are also highly tolerant to high temperature and pressure, other types of corrosive media. The construction ensures long life even with high viscosity media.

Cast Steel Gate Valve

Cast steel gate valves are characterized by the shock resistant manufacturing. They are highly flexible and have enhanced strength. Because they are resistant to high temperature and pressure conditions, they are used in oil refineries, petrochemical plants, and water treatment plants.

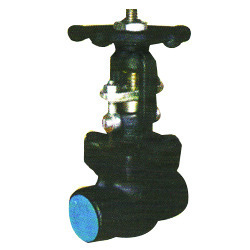

Forged Steel Gate Valve

A forged steel gate valve is formed under extreme pressure given to carbon and iron. The valve thus is made of forged steel making it highly durable. They are used in oil and gas industries, for power generation, and wastewater treatment plants.

Carbon Steel Gate Valve

Carbon steel gate valves are manufactured with forged or cast carbon and steel. It is known for its superior mechanical features like resistance to chemicals and high tensile strength. It is used in petrochemical industries and power generation, especially in relation to steam and fluid services.

Gate Valves by Bore SIze

Full Port/Bore Gate Valve

Full bore gate valve has an opening with the same diameter as the pipeline opening. The tight sealing helps in continuing the flow of the media in water treatment plants with a mixture of fluids and solids to prevent clogging of the pipeline.

Reduced Port/Bore Gate Valve

A reduced bore gate valve is more affordable with a smaller opening as compared to the diameter of the pipeline. This is better suited for smaller spaces and where there is no concern related to pressure drop

Gate Valves by Condition

Gate valves have no shortage of applications and are used for multiple purposes. The major gate valve uses are seen in the manufacturing, oil and gas industry, as well as pharmaceuticals.

High-pressure Gate Valve

High pressure gate valves are made to handle different types of media with high pressure up to 2250 psi without causing any internal or external leakage. SIO uses forged steel and stainless steel gate valves for handling high pressure conditions. They are seen in hydrocarbon processing and water treatment plants.

High-temperature Gate Valve

SIO’s gate valves are manufactured so that they can easily handle high temperature media up to 750°F. SIO uses carbon steel and stainless steel as the preferred material for high temperature conditions. They are used in petrochemical and water treatment plants.

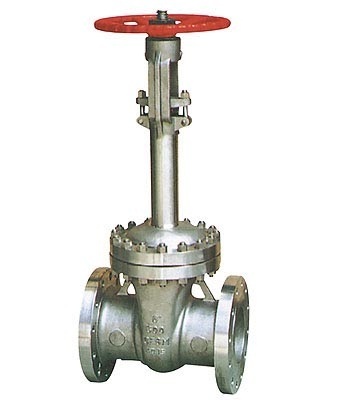

Cryogenic Gate Valve

Gate valves made of stainless steel are well equipped to handle the cryogenic temperature. They can handle high viscosity and different types of corrosive media as well. Mostly made of cast steel and stainless steel, these valves form a warm vapor area for better insulation for different valve parts. Metallurgy and oil and gas industries use cryogenic gate valves.

Gate Valves by Valve Operator

The difference in gate valves by the valve operator depends on the application. Gate valves are actuated through the use of a threaded stem monitored by a motor or handwheel.

Manual Gate Valve

A manual gate valve is characterized by its hand operated function which causes the media to flow or be blocked as per the industrial need. They can easily handle pharmaceuticals and wastewater treatment plants. Non-flammable liquids like heavy oils and slurry can be handled by manual gate valves.

Automatic Gate Valve

In contrast to manual gate valves, automatic gate valves are made to be operated via actuators. They promote safety and security of all the people in HVAC systems, chemical, food and beverage industries and plumbing. Ventilation systems and combustion engines are suitable environments for these types of gate valves.

Gate Valves by End Connection

An advantage when you consider SIO’s manufacturing of an industrial gate valve is its multiple end connections. Universal and tensile coupling is possible as well as welding.

Butt-weld Gate Valve

The butt-weld sized end connection is made so that it matches the bevel of the pipeline. The valve is then welded to the pipeline for accurate sealing. They are applied to industries with high pressure and high temperature applications.

Socket Weld Gate Valve

A gate valve with socket weld end connection is made to easily tolerate high temperature and pressure conditions. These end connections ensure that there is no internal or external leakage of the system.

Threaded End Gate Valve

A gate valve with threaded end connection has either internal or external threads used for connection to the system pipeline. It allows for easy assembly and is suitable for any system with low-pressure media piping systems.

Double Block and Bleed Ball Valves

For critical applications in which repair, maintenance, or replacement of equipment does not interrupt the system, Block and Bleed Ball Valves are ideal. This valve provides a tight shutoff that prevents contamination from entering the system.

Gate Valves by Seat Type

Different gate valve types will be manufactured with different numbers of seats depending on the end application. For instance, you will find two inclined seats on a wedge-shaped gate valve.

Resilient Seated Gate Valve

Resilient seated gate valves are perfect for easy regulation of different kinds of media and complete isolation as and when required.

Metal Seated Gate Valve

Metal seated gate valves are made easy to regulate media flow in both unidirectional and bidirectional systems without causing any kind of blockage or leakage.

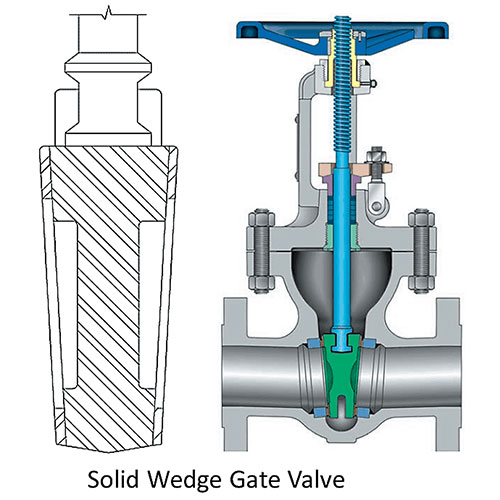

Gate Valves by Disc Type

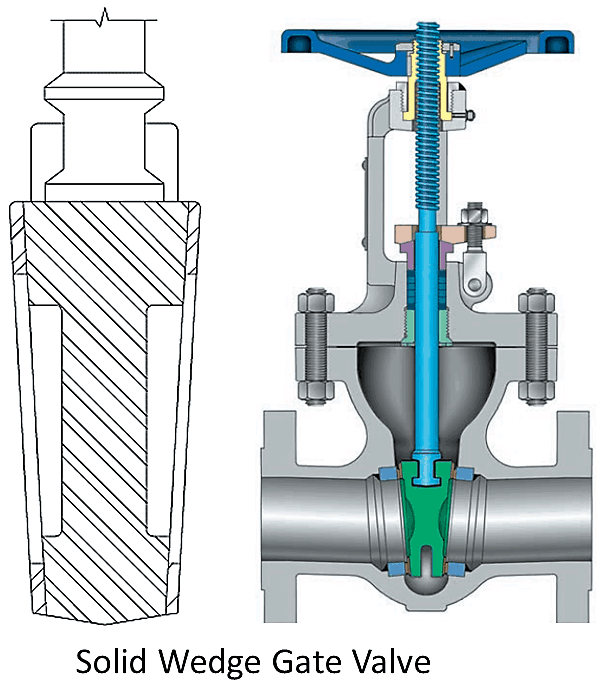

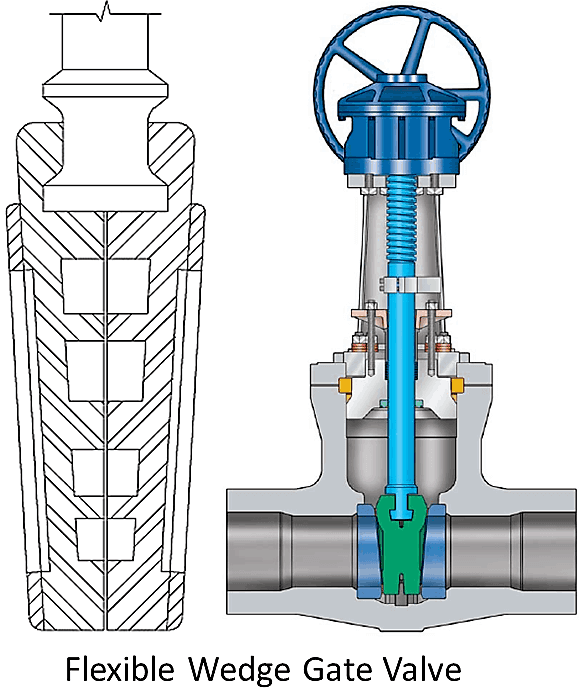

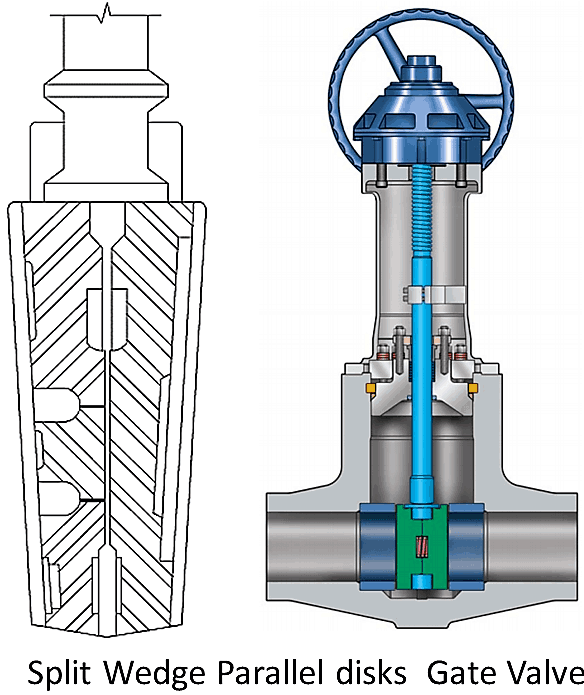

Based on the disc types, you can easily differentiate between types of gate valves. These include parallel disks, solid wedge, flexible wedge and split wedge gate valves.

Solid Taper Wedge Gate Valve

A solid taper disc is the most common type of disc and with good reason. This is so because it is better suited for a range of different media. It can also easily handle rough flow of media.

High-temperature Gate Valve

SIO’s gate valves are manufactured so that they can easily handle high temperature media up to 750°F. SIO uses carbon steel and stainless steel as the preferred material for high temperature conditions. They are used in petrochemical and water treatment plants.

Cryogenic Gate Valve

Gate valves made of stainless steel are well equipped to handle the cryogenic temperature. They can handle high viscosity and different types of corrosive media as well. Mostly made of cast steel and stainless steel, these valves form a warm vapor area for better insulation for different valve parts. Metallurgy and oil and gas industries use cryogenic gate valves.

Gate Valves by Body Bonnet Joint

The body connection in a gate valve dictates how much it prevents leakage. There are three types of bonnets in gate valves: screw-in, welded, pressure-seal and bolted. The body bonnet joint helps SIO create low-cost solutions for their clients.

Screwed Bonnet

A screwed bonnet has the simplest design and is often used for low-cost valves.

Bolted Bonnet

A bolted bonnet is the most well-known design and widely used in large and high-pressure gate valves. This design requires a gasket to seal the joint between the bonnet and valve body.

Welded Bonnet

A welded bonnet is another popular design that does not require disassembly. It is more lightweight compared to its bolted bonnet counterpart.

Pressure-seal Bonnet

A pressure-seal bonnet is often used for high-pressure and high-temperature applications. The higher the pressure in the body cavity, the greater the force on the gasket in a pressure-seal gate valve.

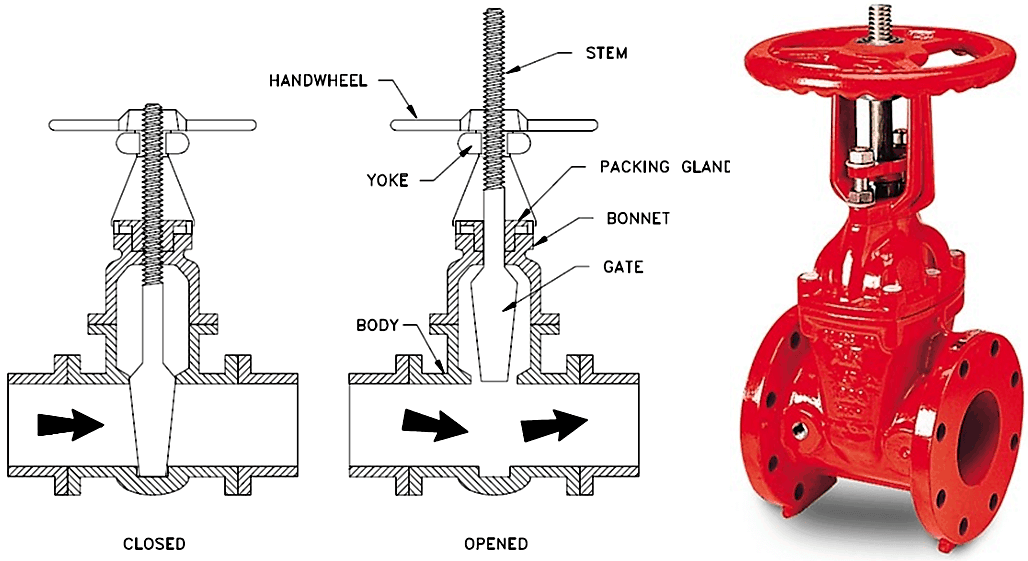

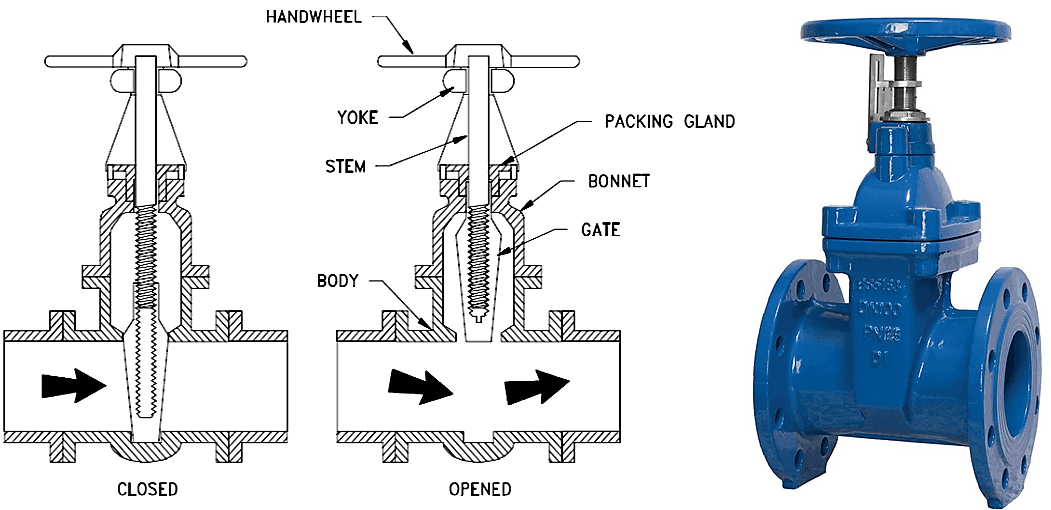

Gate Valves by Stem Movement

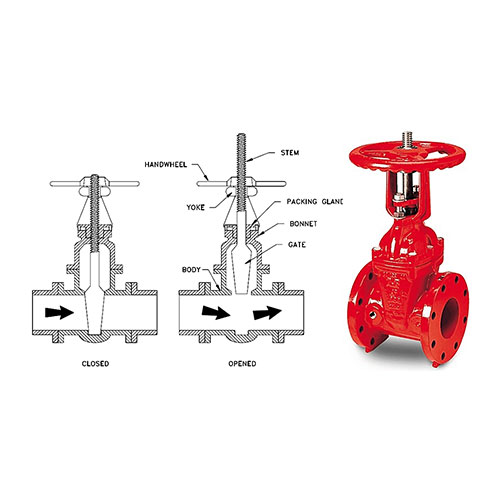

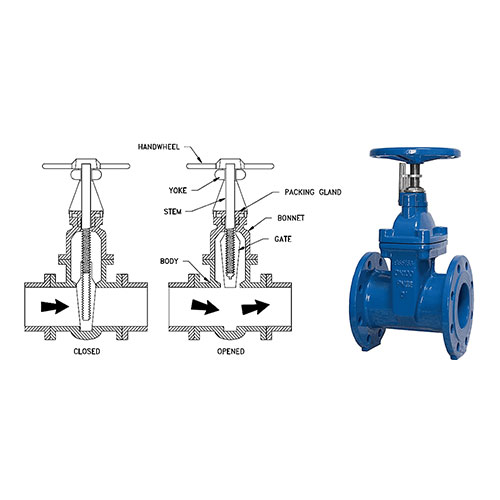

Rising Stem Type

Also called an outside and yoke gate valve because media flow is controlled by movement of the stem. The outside stem and yoke design will keep the steam and disc out of the path of the fluid. Keeping these parts will help in increasing the life of valve parts from interaction with corrosive parts.

Non-rising Stem Type

These valves are perfect for small spaces because they do not rely on stem movement for controlling media flow. They are used in industries that do not have corrosive media and need functioning in limited space.

Gate Valve Manufacturer

A gate valve, also known as a sluice valve, is one of the most widely used valves in industrial applications. It is primarily used to control the flow of process fluid. It is equipped with a flat closure component, better known as the gate, that slides into the line to restrict flow.

An ideal gate valve can cut through slurries and other viscous materials, such as grease, heavy oil, cream, molasses, and more. It is well-suited for liquid applications, such as in oil and gas industries, water and wastewater treatment facilities, pharmaceuticals, and power plants.

A gate valve is available in different sizes to handle different volumes of process flow. Moreover, it can be made from different types of materials and design features and options. This makes it difficult to choose which type of gate valve is well-suited for your application.

Since choosing the right gate valve can be complicated, we have categorized it into different types. This will help you choose which gate valve will provide you optimum performance.

How to Choose the Right Gate Valve for Your

Industrial Applications

Before buying a gate valve, it is important that you determine the requirements of your application. This is to ensure that your gate valve is reliable, effective, and has a long lifespan. Here are the important factors to consider so you can choose the proper gate valve that will serve you for a long time:

The properties of the process flow have crucial effects on the entire working system, including how a gate valve functions. It is important that you identify these properties to ensure that you are using the right gate valve. Some of the factors you need to consider are the following:

• Determine whether there is a possible chemical reaction between the process media between the materials of the gate valve and other system elements.

• Whether the process fluid is abrasive or corrosive;

• Possible chemical reactivity between the media and the materials of the valve and other system components.

Since a gate valve is suitable for various applications, it’s essential that you understand the specific operation and function. This helps you choose which gate valve type is ideal for your application.

For instance, does the gate valve need to control or release system pressure? How much leakage can the entire system handle? How accurately should the gate valve be able to control process flow? These questions will guide you in choosing the right gate valve that ensures reliability and safety.

The shut-off function of a gate valve is also useful in managing hot and cold fluids. It is also important that you determine the temperature of the process flow. This helps you choose the proper make of your gate valve. Various materials are used in the manufacture of gate valves, such as stainless steel, carbon steel, cast steel, carbon steel, and more. Each of these materials are well-suited for specific temperature ranges.

The shut-off function of a gate valve is designed to endure different pressures of fluid. It is essential that you identify the pressure range that will go through the gate valve. This helps you choose the right size and maximum pressure capacity to handle such working conditions.

Choosing a gate valve also includes considering how it works with the rest of the system. For instance, a small gate valve is ideal when there is limited workspace but cannot handle higher pressures that might be present in the application.

Cleaning and maintenance must also be considered as they affect the performance of the working system. Is the gate valve accessible and can it be cleaned easily? How often does the gate valve need maintenance? Answering these questions helps you determine whether or not a gate valve is suitable and practical for the entire system.

The application may have other specific requirements for gate valves and the industry may need them to meet certain standards. For example, some applications require strict sanitary guidelines and noise level requirements. These factors affect which type of gate valve you’re going to choose for your application. Other specifications will also include:

- Wedge Design

Since it is the sealing component of a gate valve, choosing the wedge design is crucial. When doing so, you must take the following into consideration:• Wedge nut

This part joins the wedge and stem together and has two basic designs:

⊗ Loose wedge nut design – This design has a brass nut that moves into a hole in the wedge core.

⊗ Fixed wedge nut design – A fixed wedge nut design has a nut that expands in the wedge core.

With this design, some moveable parts can no longer be moved. This eliminates the risks of corrosion, which may be a result of moving components causing damage to the surface of the rubber.

• Wedge shoes and guides

The wedge is continually exposed to stress and friction when the gate valve opens and closes. Wedge guides that correspond to grooves in the valve body help stabilize the position of the wedge. This also ensures that the stem does not lean downstream as a result of flow velocity.

Meanwhile, wedge shoes ensure that the rubber on the surface of the wedge does not worn out as caused by traction between the guardrail and wedge in the valve body.

• Rubber

It is essential that the wedge is hardened with rubber for the tightness of the gate valve. Moreover, the rubber volume on the sealing surface of the wedge must be enough to absorb contamination in the seat.A strong bond between the wedge core and rubber is vital to ensure proper sealing even when the rubber is cramped. This is also to prevent corrosion even if pointed materials go through the rubber when the gate valve closes.

- Rubber Quality

Rubber quality is important to ensure durability and optimum function of a gate valve. The rubber should endure continuous effects from chemicals and impurities without getting damaged. It should also absorb small contaminants in the valve seat to ensure tight sealing.When checking rubber quality, take note of the following:

• Compression set

This refers to the ability of the rubber to reclaim its original state after being compressed. When the compression set has high-quality, the rubber will have better capacity to regain its state. It will also ensure a 100% positive seal for a long time.

• Biofilm formation

When used for water treatment, organic substances may travel from the rubber material and provide nutrients to microorganisms. This could lead to formation of biofilm that will contaminate drinking water. Choose a gate valve with a wedge rubber that guarantees less biofilm formation.

• Resistance to chemicals for water treatment applications

Chemicals such as chlorine are widely used to clean and disinfect pipelines. They are also used to make sure that water is safe for drinking. The rubber material must not crack or degrade due to chemical treatment of water.

• Approval for drinking water

All rubber materials that come in contact with water must have an approval that it is safe for drinking. If there are no local approvals required, rubber materials that come in contact with drinking water directly must have major approvals, such as KIWA and NSF/ANSI/CAN 61.

- External Protection From Corrosion

External protection from corrosion is crucial to the lifespan of the gate valve. It is highly recommended to have an even distribution of epoxy coating that is in accordance with DIN 3476 part 1 and EN 14901. It must also have:

• Layer thickness

All areas must have a minimum of 250 μm.• Impact resistance

A stainless steel cylinder is released on a coated surface through a one-meter tube. The component must be tested electrically after each impact. There should be no electric breakthrough after the test.• Blast cleaning

Blast cleaning must be in compliance with ISO 12944-4.• MIBK test

The treatment of epoxy coating should be inspected in an MIBK test or cross-linkage test. A drop of methyl isobutyl ketone is applied on a component. After thirty seconds, the test component is wiped with a white cloth. The cloth should remain clean and the test area should not be smeared or matted. - Tight Construction

There are two essential design features:

• Body/Bonnet sealing

Tightness between the body and bonnet can be achieved through a gasket installed in a recess in the gate valve. This design guarantees that the gasket will stay properly positioned and prevents it from blowing out due to pressure surges.

To protect the bonnet bolts from corrosion, the gasket must enclose the bolts. The bolts must also be installed in the gate valve in a way that threads are not exposed to the surroundings.

• Stem sealing

Stem sealing must be maintenance-free and must last the lifespan of the gate valve or achieve the service life requirements according to EN 1074-2.

The primary seal that retains the internal pressure is recommended to have a hydraulic seal to provide a tighter seal during a surge in internal pressure. To protect sealing from contamination, a sealing must be installed around the stem on the top. Moreover, backup seals must be installed around the stem

- General Performance

When a gate valve is operated manually or automatically, it is essential to take note of the operating torque and closing torque.

• Operating torque

Depending on the valve size, the torque required to operate a gate valve from an open to a closed position must be between 5 Nm and 30 Nm.

It is essential to take note that a gate valve with an operating torque no more than 5 Nm promotes the valve operator to close the gate valve quickly. This could lead to pressure surges and water hammer in pipelines.

• Closing torque

This is the torque required to close a gate valve to a bubble-tight position. When the valve is operated manually, it should be against the diameter of the handwheel so that it does not give the operator a lateral force of more than 30 to 40 kg.

When actuated, the torque should fall within the limits of the actuator. Take note that actuators typically have a wide torque range. However, the ISO flange connection used usually determines the choice of actuator used.

Generally, gate valves with ISO flange connection must have maximum closing torques as stated below:

ISO Flange F-16 – maximum 1000 Nm

ISO Flange F-14 – maximum 500 Nm

ISO Flange F-10 – maximum 120 Nm

What Are the Different Types of Gate Valves?

Gate valves are mainly used to provide tight sealing in a variety of industrial applications. However, there are many types of gate valves that differ in materials, pressure and temperature ratings, valve operator, etc. To provide you better understanding and determine which type of gate valve you need, here are the different categorizations of gate valves:

Gate Valves by Material

Stainless Steel Gate Valve

A stainless steel gate valve is widely used for its durability and high resistance to abrasion and corrosion. It is well-suited for an array of industrial applications that deal with severe working conditions. These may include extremely high pressures and temperatures, severely low pressures, cryogenic temperatures, chemicals, and other corrosive media.

Because of its increased strength and tolerance to various chemicals, a stainless steel gate valve can handle different properties of media flow. Some examples are high viscosity, mixed solids, slurries, and more. It can also ensure a positive shut-off and has a really long service life.

Forged Steel Gate Valve

A forged steel gate valve is a type of valve made from an alloy of carbon and iron compressed under extreme pressure. The end product is forged steel, which makes the gate valve durable and ideal for a variety of industrial applications.

Due to the enhanced strength, forged steel gate valves are ideal for high-pressure and high-temperature applications. They are often used in oil and gas industries, water and wastewater treatment facilities, and power generation.

Cast Steel Gate Valve

A cast steel gate valve is made from various types of steel giving it shock resistance and enhanced strength. A gate valve made from cast steel goes through a process wherein metals from their liquid state are molded and solidified to form valve components. Because of this, cast steel gate valve is flexible and is ideal for customization to meet specific requirements.

Cast steel also gives a gate valve increased temperature tolerance, making it ideal for various applications with different pressure and temperature ranges. This type of gate valve is commonly used in pipelines, oil refineries, chemical and petrochemical plants, and water and wastewater treatment plants.

Carbon Steel Gate Valve

A carbon steel gate valve is made from carbon steel that is either cast or forged. A major benefit of carbon steel is it has enhanced mechanical features. This makes this valve type highly resistant to stress, corrosion, and sulfides.

Another benefit of a carbon steel gate valve is it has high tensile strength. This means it is well-fitted for high-pressure utility applications, such as steam, gas, and water services. Other industries that use a carbon steel gate valve are petrochemicals, oil and gas, wastewater treatment, and power generation.

Gate Valves by Bore Size

Full Port / Full Bore Gate Valve

A full port gate valve refers to a gate valve with an opening that has a similar diameter with the pipeline it is used in. It provides unrestricted flow and is suitable for applications that require free flow and tight sealing.

A full port gate valve is often used in applications that require low flow resistance. It is also used in process flow that contains mixed liquids and solids where flow restrictions may separate the components leading to buildup or clogging.

Also known as a full bore gate valve, this valve type provides low friction loss, small pressure drop, and maintains flow rate consistency. These features help maintain the integrity of the gate valve, increasing its service life.

Reduced Port / Reduced Bore Gate Valve

A reduced port gate valve means the gate valve has an opening smaller than the diameter of the pipe. It has a straight flow path making the gate valve more confined on the inside. The main advantage of a reduced port is its affordability and compact size.

Also known as a reduced bore gate valve, this type of gate valve is often used wherein an increased pressure drop is not a concern. It is also used when the valve size and operations cost are essential factors.

Source: Indiamart

Gate Valves by Body Bonnet Joint

Screwed Bonnet

A screwed bonnet has the simplest design and is often used for low-cost valves.

Bolted Bonnet

A bolted bonnet is the most well-known design and widely used in large and high-pressure gate valves. This design requires a gasket to seal the joint between the bonnet and valve body.

Welded Bonnet

A welded bonnet is another popular design that does not require disassembly. It is more lightweight compared to its bolted bonnet counterpart.

Pressure-seal Bonnet

A pressure-seal bonnet is often used for high-pressure and high-temperature applications. The higher the pressure in the body cavity, the greater the force on the gasket in a pressure-seal gate valve.

Gate Valves by Disc Type

Source: Hardhat Engineer

Solid Taper Wedge Gate Valve

A solid taper wedge valve disc is the most commonly used disc type due to its simplicity and durability. A gate valve with a solid taper wedge can be installed in any position. It is suitable for almost all fluid types as well as turbulent flow.

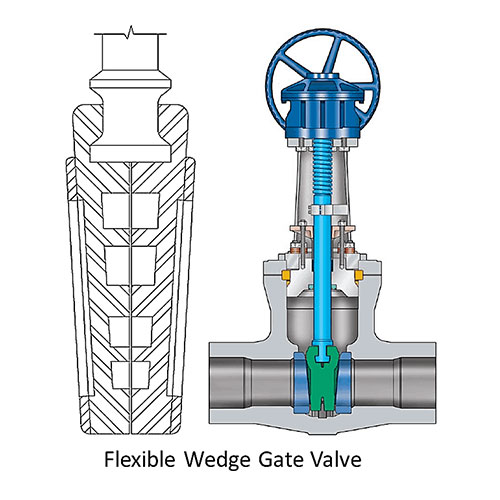

Flexible Wedge Gate Valve

A flexible wedge disc is a one-piece solid disc with a cut around the frame. The cut varies in shape, depth, and size. A shallow cut on the wedge frame provides limited flexibility but contains more strength. Meanwhile, a deeper cut on the wedge frame provides more flexibility but has decreased strength.

A flexible wedge design enhances seat alignment and provides better leak sealing. It also improves performance in applications where thermal binding is possible. Thermal binding is common in applications that handle steam wherein a higher torque is required. This makes a flexible wedge gate valve ideal for steam pipelines and other similar applications.

Source: Hardhat Engineer

Source: Hardhat Engineer

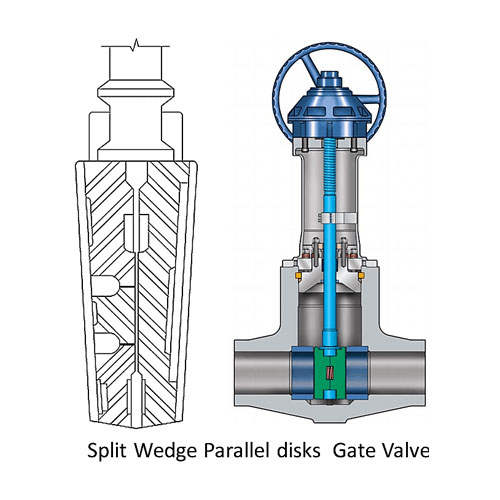

Split Disc Gate Valve

A split disc is made of two solid components that hold together through a special mechanism. In this mechanism, one-half of the disc is out of alignment. This allows the disc to freely adjust itself to the seating surface.

The freedom of movement of the disc prevents thermal binding even when the gate valve has been closed when a process line is cold. This means that when a line becomes hot by process fluid and expands, it does not produce thermal binding.

A split disc can be in a parallel or wedge shape disc type:

Parallel Disc Gate Valve

A parallel disc is spring-loaded, so it is always in contact with the valve seat and gives bi-directional sealing.

Split Wedge Disc Gate Valve

A split wedge disc is well-suited for handling non-condensing liquids and gases at normal and high temperatures.

Gate Valves by Stem Movement

Source: Hardhat Engineer

Rising Stem or OS & Y Type (Outside Stem and Screw Type)

Also known as an outside stem and yoke (OS & Y) valve, a rising stem gate valve has a stem that goes up when opening the gate valve and goes down when closing the valve. The smooth portion of its stem is exposed to the media flow and the stem will rise above the handwheel. This means that this design removes both the stem and the disc from the flow path when the valve is open.

Non-rising Stem Type

In a non-rising stem gate valve, there is no upward movement of the stem from the valve bonnet regardless of the position of the valve. The valve disc, which is threaded internally, travels along the stem similar to a nut when the stem rotates. In this design, stem threads are exposed to the flow medium. Therefore, it is widely used in applications that have limited space.

Also known as an inside screw valve, this valve type is suitable for process media that does not cause corrosion, erosion, and wear and tear to the stem material.

Source: Hardhat Engineer

Gate Valves by Valve End Connection

Source: Engineering 360

Butt-weld Gate Valve

A butt-weld gate valve means the gate valve has a butt-weld sized end connection. This connection type is designed in such a way that each end of the gate valve is slanted to match the bevel and thickness of the pipe. After this process, the two ends are “butted” to the pipe and welded. A butt-weld connection is often used in steel gate valves.

A butt-weld gate valve has increased strength, making it suitable for high-pressure and high-temperature applications.

Socket Weld Gate Valve

A socket weld gate valve refers to a gate valve with a socket weld end connection. This end connection type is socketed so the pipe has a plain spigot end. It is used in gate valves made with steel and in applications that handle high pressure and temperature. This connection type guarantees leak-proof and a long service life.

Threaded End Gate Valve

A threaded end gate valve is a type of gate valve with internal or external threads for its end connections. This type of end connection is well-suited for low-pressure piping systems. It is affordable and ensures fast and easy assembly.

Flanged End Gate Valve

A flanged end gate valve refers to a gate valve with flanged end connections. This type of connection is one of the easiest to install and/or uninstall in a pipeline. Because of this, it is the most commonly used connection among industrial valves.

A flanged end connection is secured with several bolts to securely fasten the gate valve to the pipe flanges. This design allows the gate valve to have less tightening torque compared to other connection types. Aside from gate valves, flanged end connection can also be used in other valves, such as ball valves.

Gate Valves by Seat Type

Source: Water Online

Metal Seated Gate Valve

A metal seated gate valve is ideal for applications that require irregular operations and where the wedge is kept fully open or closed. It is known for durability, flexibility, and for having a long lifespan.

This type of gate valve has a metal seated wedge mainly used for isolation of flow in a pipeline or equipment. Its conical wedge design and angular sealing components require a depression at the bottom of the valve to ensure a positive shut-off. It is commonly used in irrigation systems, stormwater systems, and wastewater treatment systems.

Resilient Seated Gate Valve

Resilient seated gate valve is a gate valve made with a ductile iron wedge gate. The gate is fully enclosed with a protective coating, such as Polyurethane and EPDM rubber. It can be made with different end connections, such as flange by flange and flange by groove.

The highlight of resilient seated gate valve is it provides a low-operating torque; therefore, increasing the service life of the valve. It is commonly used in high-pressure and high-temperature applications in water and wastewater treatment plants, chemical and petrochemical facilities, power generation, and oil and gas industries.

Source: Indiamart

Gate Valves by Condition

High-pressure Gate Valve

A high-pressure gate valve is specifically designed to provide tight sealing in high-pressure applications. It is made with durable materials, such as stainless steel and forged steel. This is for the gate valve to withstand harsh conditions and to have a long service life.

This type of gate valve is equipped with a pressure seal bonnet, which is ideal for high-pressure applications, particularly those exceeding 2250 Psi. The special feature of this construction is that the bonnet is in a downward position that fits inside the valve body. This design improves the bonnet-body seal as the internal pressure increases, ensuring leak-proof operations.

A high-pressure gate valve is widely used in applications that generally deal with harsh working conditions. These include manufacture of chlorine, hydrocarbon processing, oil refineries, wastewater treatment facilities, and more.

High-temperature Gate Valve

A high-temperature gate valve is made in a way that it can endure temperatures as high as 750°F (400°C) in various industrial applications. It is made with sturdy materials, such as carbon steel, stainless steel, duplex, super duplex, and Inconel.

Aside from high temperatures, this type of gate valve is also suitable for handling corrosive media, vacuum, high viscosity, and high pressure. It is commonly used when dealing with mixed solids and liquids, slurries, and other viscous components.

Due to its high tolerance to different pressure and temperature, a high-temperature gate valve is used in almost any industry. These include chemical and petrochemical industries, petroleum plants, and power generation to name a few.

Source: Steamflo

Source: Indiamart

Cryogenic Gate Valve

A cryogenic gate valve is particularly designed to handle industrial applications that deal with extremely low or cryogenic temperatures. It is generally made with stainless steel, cast steel, and carbon steel. It is equipped with an extended bonnet for the stem packing to remain functional and away from the extremely cold fluid. This also creates an area of warmer vapor to insulate the stem seal against the effects of cryogenic temperature.

A cryogenic gate valve is often used in applications that handle compressed natural gas (CNG), liquefied natural gas (LNG), and ethylene. It is also used in other cryogenic applications, including gas production plants, low-pressure trailers, and tank services.

Gate Valves by Valve Operator

Manual Gate Valve

A manual gate valve is a hand-operated valve that uses a wheel or gear to open and close media flow. It is made from stainless steel, carbon steel, brass, cast iron, and certain types of plastic.

A manual gate valve is generally sturdy and is often used in critical working conditions. It provides accurate blocking and releasing of process flow. It also allows the operator to control the media flow easily whenever necessary.

Since there is low velocity, using a manual gate valve creates a low-pressure drop and decreases the risk of system wear. Moreover, it creates a high flow capacity as the operator can directly control the flow.

Automatic Gate Valve

A gate valve may be automatically operated through the use of actuators. The main advantage of using an automatic gate valve is it promotes safety for the operator and the entire system.

Pneumatic Actuator Gate Valve

A pneumatic actuator gate valve is a type of valve that uses a pneumatic actuator that changes compressed air to mechanical energy. Since it uses air as its power source, a pneumatic actuator is completely safe and reliable. A pneumatic actuator valve is widely used in HVAC systems, plumbing, chemical applications, and other industrial services.

Electric Actuator Gate Valve

An electric actuator gate valve refers to a gate valve automatically operated through an electric source. An electric actuator allows a gate valve to open and close slowly, greatly reducing the risks of a water hammer. This type of actuator is widely used in industrial applications as it is non-toxic, safe, quiet, and efficient.

Contact Our Experts

Send us a message if you have any questions or request a quote.We Offer:

- A reply from our experts within 24 hours

- The latest detailed product catalugue

- One-stop service for your project