Globe Control Valves

Features

- Features & Benefits

- Compact rugged valve body with integral flanges

- Precision manufactured valve components provide smooth operation

- Durable rugged plug and seat construction shuts off tightly

- Oversized bearings and shafts to handle high pressure drops

- Threaded valve stem connection and split stem connector provide zero backlashes and assures minimum dead band and hysteresis

- Factory lubricated packing and valve stem minimizes hysteresis from packing friction

- ANSI Standard valve body face to face dimensions and bolt patterns

- Bolted bonnet can be easily removed for easy access to trim for inspection and repair

Materials:

Body: Carbon Steel (WCB) or Stainless Steel (CF8M)

Trim: SS, RPTFE, or PEEK

Cage, Stem, & Seat Ring: 316 SS

End Connections:

150# Flange: 1/2″ to 4″

300# Flange: 1/2″ to 4″

NPT:

1/2″ to 2″

Socket Weld:

1/2″ to 2″

Temperature Range:

-20°F to 800°F

Max. Shut-off Differential Pressure:

Varies with model and options

Range ability:

50:1

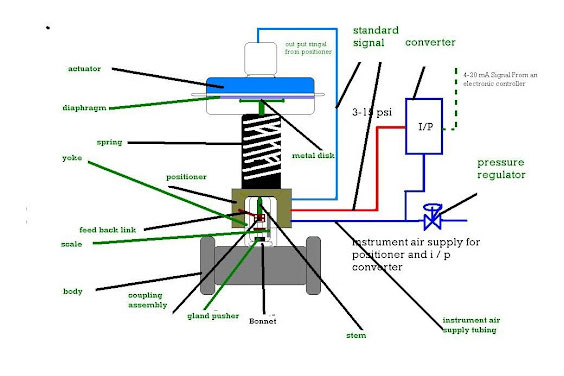

Available Actuators:

Electric

Pneumatic Diaphragm

Pneumatic Cylinder (special order)

Manual Hand Wheel

Contact Our Experts

Send us a message if you have any questions or request a quote.We Offer:

- A reply from our experts within 24 hours

- The latest detailed product catalugue

- One-stop service for your project