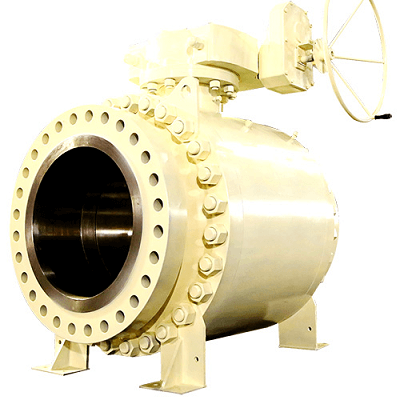

A trunnion ball valve is one of the many types of ball valves. It is a quarter-turn valve that has a perforated and supported/ fixed ball to manage flow that passes through. The trunnion mounted ball valve design has an added mechanical anchoring at the top and bottom of the ball. This trunnion mounted stem takes in the pressure, preventing more friction between the ball and seats. This allows the operating torque to remain low even at high-working pressure.

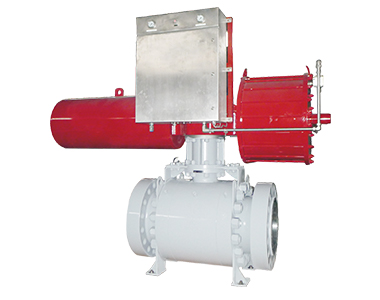

SIO trunnion mounted ball valves have many custom options. They are available in both two-piece and three-piece designs and have different seat layout choices. Many valve operator types are available including bare stem, hand lever, hydraulic actuator, pneumatic actuator, motor-operated actuator, and more. SIO provides customization to offer clients the best solutions for their specific requirements.

As one of the top trunnion ball valve manufacturers, SIO offers trunnion mounted ball valves that have an array of benefits. Their design ensures central positioning even in applications with extreme pressure. Thanks to their independent-floating spring-loaded seats, a tight seal is guaranteed even at low differential pressures. The bolted body design of the API 6D ball valves promotes simpler service and maintenance. This makes them suitable for above and buried installations.

Trunnion Mounted Valves Design Featuress

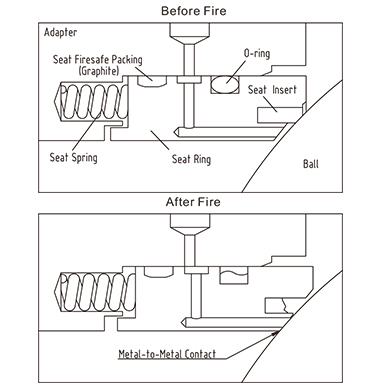

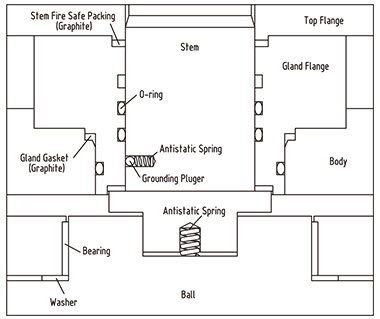

Fire Safe Design

A. Internal Leak Prevention

SIO’s internal leakage prevention is ensured by an O-ring design. When the primary O-ring is damaged by plant fire, the spring-loaded metal seats will come in contact with the ball to shut off fluid flow. This will minimize the leakage of the internal process medium. The secondary graphite seal will also prevent leakage between the seats and valve caps during and after the fire.

B. External Leak Prevention

The external leakage prevention is double insurance to the fire-safe function. The primary O-ring and secondary graphite gasket will seal possible external leakage between the stem and gland flange, gland flange and body, and body and adapter. When the resilient o-ring gets burned out by fire, the secondary graphite gasket seal can still prevent external leakage of the process medium.

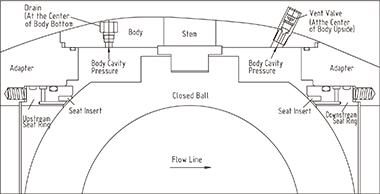

Double Block and Bleed (DBB) Function

The DBB function is essential to maintain the overall integrity of the system. It allows the whole live operation to continue even when essential equipment needs repair or maintenance. It will shut off the fluid flow on the upstream and downstream sides of the ball. It will isolate the valve bore and cavity from each other when the valve is fully open or closed. This is to depressurize the cavity through a bleed or vent valve and a drain plug.

Antistatic Device

An antistatic device is an excellent addition for further fireproof safety. Antistatic spring-loaded balls are attached between the stem and the bonnet and between the stem and the ball. They will maintain electrical conductivity in all metallic components. The antistatic device will also reduce the static charge on the ball due to friction. It protects the valve from a spark that could ignite the fuel passing through the valve.

Blow-out Proof Stem

The stem is made separately from the ball with integral T-type round shoulder, retained by the gland. Stem and ball isolation prevents wearing of the downstream seats enhancing the performance and lifespan of the valve.

A blow-out proof stem means inserting the stem from the inside of the valve body. It is necessary when there is excessive pressure on the ball seats. The pressure in the valve body will push the stem up when the valve is open or closed. The stem housing, which is connected to the body, will hold the stem in position. Therefore, the stem will remain secure by the stem housing even when the valve is under pressure.

Ball Seat Alignment

All valves have mechanical stops to maintain the integrity of the ball and prevent it from over-rotating. They are useful when there’s a need to control or adjust the flow rate. It also limits stem travel at a certain degree in the upstream or downstream direction due to the capacity limitation of the valves.

AED O-ring

AED O-rings guarantee smooth and leak-free services in high-pressure applications. For example, in hydrocarbon processing under class 600 and above, the molecular structure of elastomeric O-rings might absorb the gas. This exposes the valve to sudden decompression, which may damage the O-rings. AED O-rings or lip seals are designed for such demanding environments preventing any potential leaks.

Environment-friendly Valve

The fugitive emission-suppressing design is ISO 15848 certified, which verifies the low-emission performance of the full sealing mechanism of the valves. One significant benefit of environment-friendly valves is it promotes sustainability. If operations are less dependent on natural resources, businesses will have better ways of dealing with rising costs caused by climate change.

Customized Seat Designs

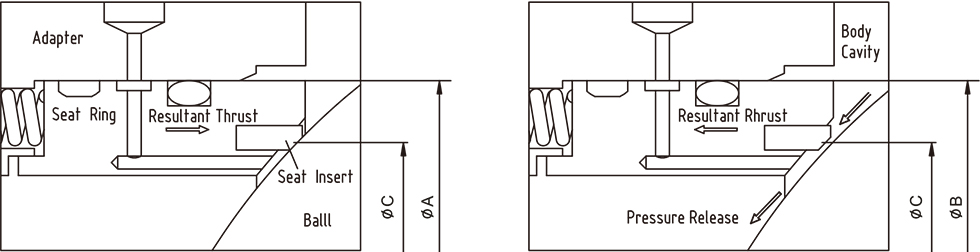

A. Standard: Single Piston Effect Seats (Self-relieving Seats)

The standard single piston effect seats are self-relieving seats that are well-suited for medium pressure, both upstream and downstream. They create a resultant thrust to the seat rings against the ball to ensure tight sealing. Meanwhile, medium pressure acting in the body cavity creates a resultant thrust to push the seat rings away from the ball.

The single-piston design allows the automatic release of any pressure in the body cavity when the valve is in the fully open or fully closed position.

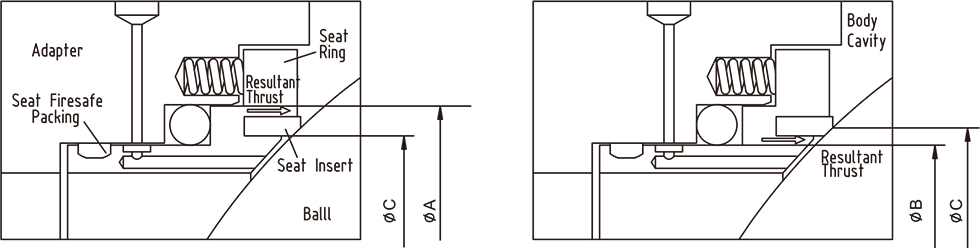

B. Option 1: Double Piston Effect Seats

The double-piston design is for medium pressure from the upstream and downstream as well as in the body cavity. The pressure creates a resultant thrust that pushes the seat rings against the ball. Ball valves with double-piston effect seat rings require a cavity pressure relief device to reduce pressure build-up in the body cavity.

C. Option 2: Combinations Seats

We offer the combination of the two seats upon request. This is a standard seat design used for the upstream side and a double piston effect seat design for downstream. The advantage of this design is it can achieve double piston effect seat function without cavity pressure relief. This promotes easy installation, maintenance, and less expenses.

How Does a Trunnion Mounted Ball Valve Work?

A trunnion mounted ball valve has a sphere-shaped disk to start or stop the flow. This disk has a port, commonly referred to as a bore, in the middle portion. It becomes open and will allow liquid flow when the valve is positioned so that the port is in the same angle as the pipeline. When the port is turned 90 degrees, the ball valve will close. This closes the flow path and keeps any substances from passing through.

The anchoring system of the trunnion mounted valve allows it to absorb more pressure from the pipeline. This will prevent excess friction that might affect operations and the lifespan of the valve. It also comes with an extended stem, which makes it applicable for both cryogenic and high-temperature applications.

Ball valves are known for their reliable and bubble-tight sealing. This makes them ideal for gas applications where a tight shutoff is needed. However, due to the chances of wearing on the seats, they are not suitable for throttling applications.

Most ball valves are designed with stop measures that only allow a 90-degree rotation. However, there are now ball valves that can close up to 360 degrees. Having a 90-degree rotation is technically enough for ball valves to function effectively. However, there are special cases where it’s more ideal to have the full movement of ball valves. Most of these apply in the oil and gas industry where hazardous chemicals need a secure and fast shutoff.

Applications for Trunnion Mounted Ball Valves

Industrial Gas Processing Plants

Industrial gas process plants are generally huge and costly and any mistake is a significant expense on the industry. SIO trunnion mounted ball valves provide accurate flow control, which is essential in these plants. With their tight shutoff feature, they will promote the overall performance, reliability, and safety of the processing plants.

LNG Plants

SIO trunnion ball valves will help provide precise flow control for LNG plants. With our environmentally-safe and reliable valves, LNG plants will become compliant with environmental standards. They will also have reduced noise, fugitive emissions, and vibration, thus ensuring smooth and steady operations.

Chemical Industry

Our trunnion mounted ball valve design offers different ranges of temperature and pressure ratings. This is useful in the chemical industry where a perfect shutoff is necessary. Our trunnion type ball valves are also ideal for handling hazardous media. They are made with special materials, like a stainless steel sealant, for durability and long service life.

Hydrocarbon Processing

We have AED o-rings for our trunnion ball valves available per request. These o-rings are suitable for high-pressure gas applications, particularly hydrocarbon processing. Due to these demanding operations, the typical o-rings may suffer damages. AED o-rings are designed for this type of environment, promoting tight sealing with no errors. This will help achieve optimum performance and cost-efficiency.