What is a gate valve?

A gate valve is a common valve used mainly in water supply systems to control the movement of the fluid. Considering its linear motion isolation, the valve acts as a gate that can either withdraw the liquid or allow the flow of the fluid. However, the question arises what is a gate valve in plumbing? or what is gate valve used for?

Well, the main purpose of the gate valves is to keep certain parts of the water supply system isolated from the main while maintenance or any kind of repair work. The unhindered water flow through this valve ensures a minimum loss of pressure in the valve. It moves in a perpendicular position to enable the flow of water.

In a fully open gate valve, the disk inside the valve is completely removed and the water can flow through swiftly. Contrary to this, the seat and the disk of the valve should be in 360-degree contact to stop or seal the flow.

One of the significant factors to consider while using the gate valve is that what is the purpose of the gate valve? it is not too efficient in quarter-turn and therefore should be opened or closed completely. You can opt for either an automated or manually operated valve as per your business needs. However, there is a greater preference for the manual valves as they are cost-efficient and the gate valves are not utilized frequently, contrary to this the automated gate valve might be a bit costly.

Gate Valve Symbol

It is important to have an idea about the symbols of the different valves so that you can easily decode them on the diagram of the pipe and the entire water system. Moreover, the knowledge of the symbol would be beneficial for the business as well. The symbol of the great valve appears as a bowtie wherein two lines cross each other forming an ‘X’. Furthermore, an enclosed shape is created by connecting two vertical lines to the ends. In simple words, its two triangles joined together with a vertical line between both.

What Is A Knife Gate Valve?

A knife gate valve is mainly used in piping systems with a greater percentage of suspended solids and other corrosive materials. They are cost-effective and lighter in weight. Their sharp blades can easily cut through the heavier liquids. Thus, it can work efficiently even in the most challenging environments.

What Is A Resilient Wedge Gate Valve?

A resilient wedge gate valve consists of a rubber-sealed wedge that not only prevents the building up of sand or debris. Furthermore, its ductile iron core can easily handle the change in pressure and temperatures.

Common Types Of Gate Valves

The different types of gate valves can be determined on the basis of their movement and closure as well. Wafer gate valve, spring-loaded gate valves, ball gate valves, swing gate valve, and diaphragm gate valve.

Wafer Gate Valve: They include a butterfly or wafer style disc and allow straight flow without hindrance. Moreover, it can be used interchangeably.

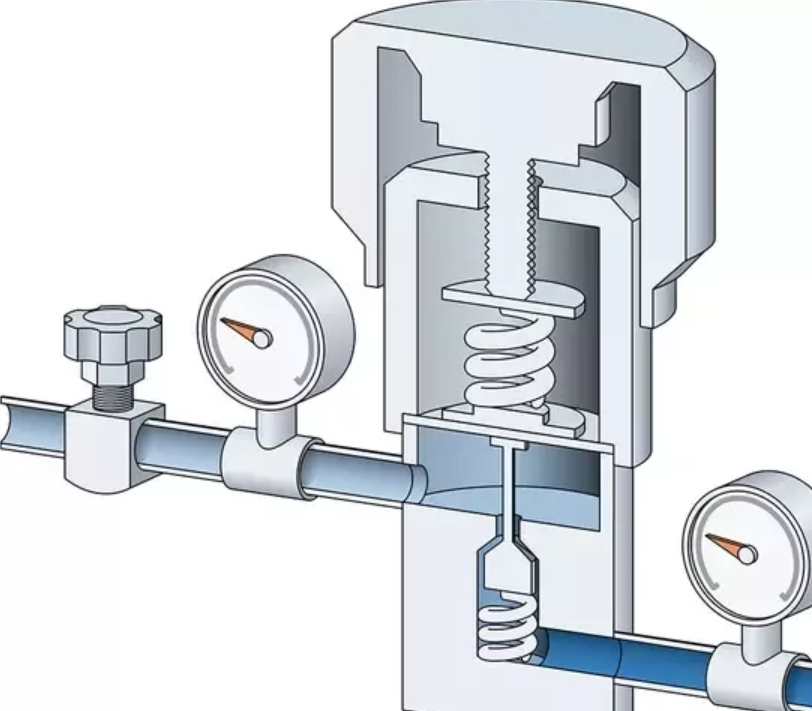

Spring Loaded Valve: It can be further classified into two types spring-loaded in-line and spring-loaded Y. They are the most common and easy-to-understand valves. The spring-loaded in-line help in preventing any kind of pressure surge in the line. On the other hand, the spring-loaded Y has a similar function as the in-line but its moveable parts allow easy inspection and servicing while it is still connected to the system.

Ball Gate Valve: This type of valve consists of a spring-loaded ball placed mainly on the valve sealing seat to create an appropriate seal and prevent the backflow of the fluid.

Diaphragm Gate Valve: This type consists of a rubber diaphragm that flexes with the increase in pressure. In case of backward pressure, the diaphragm will seal the valve to prevent the flow. They are an ideal choice in a vacuum and low-pressure applications.

Swing Gate Valve: They consist of the titling disk that opens when inlet pressure is applied and shuts off when the inlet pressure decreases.

The different types of gate valves can also be determined based on their parts such as the disk, bonnet joints, and stem movement. It is important to select the valve type based on your business requirement. Let us understand the different types of gate valves in detail to get a clarification of each type.

Types of Gate Valve Disks

Solid Taper Wedge: Its simple and strengthened design makes this type of disk most common. It can be used for any fluid including turbulent flow and can be installed with ease. However, its drawback is its high susceptibility to leakage. If subjected to high temperatures there can be a severe thermal lock.

Split Wedge: It consists of two disks joined together in a specific mechanism. Due to their parallel arrangement, the split wedge disks are also considered parallel disks. Being spring-loaded they are always connected to the seat and provide sealing in two directions. They are suitable for non-condensible gases and fluids at higher or normal temperatures.

Flexible wedge: It is a single piece with a cut around the edges. These cuts can be present in varying shapes and sizes. A narrow cut would provide lesser flexibility and greater strength, whereas a deep cut provides greeted flexibility and lesser strength. There is a better seat alignment and also tightened to prevent leakage. The biggest drawback is that the fluid might collect into the disk and weaken it in the long run.

Types Of Gate Valve Bonnet Connection

Screwed Bonnet: It is simply designed bonnet connection mainly used in cheaper valves.

Welded Bonnet: They are lighter than bolted bonnets and do not require any kind of disassembling.

Pressure-seal Bonnet: Mainly used for higher temperature and pressure. The cup placed in a downward position in the valve allows improved seal. This is because with the increase in the pressure of the internal liquid there will be an outward movement of the cup for a better seal.

Bolted Bonnet: Used in the majority of valves, the bonnet and valve are sealed through a gasket in this type of bonnet.

Types Of Gate Valve Stem Design

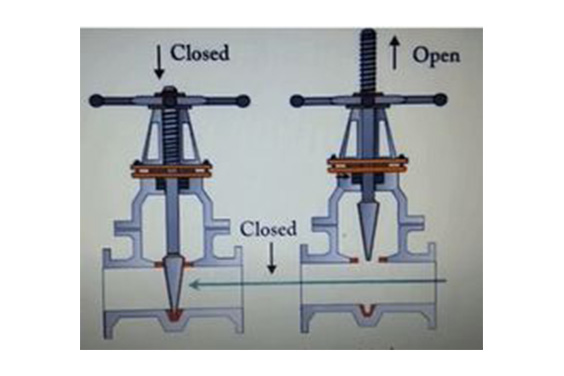

Rising Stem: In this type of stem design, there is an upward movement of the stem when the valve opens while a downward movement when it closes. This happens mainly because, in the inside screw, the threaded part of the stem is connected to the medium, therefore when the valve is opened, there is a rising movement of the handwheel along with the stem. Contrary to this in the outward screw, only the smooth part of the stem is connected to the medium of flow, therefore when the valve opens, the stem moves above the handwheel.

Non-rising stem: In contrast to the rising stem, the non-rising stem lacks any kind of upward movement. The disk of the valve is threaded inside. The stem threads are exposed to the medium, thus the disk and the stem rotate simultaneously. Such a stem design is appropriate for limited spaces and wherein the flow medium does not cause any harm to the material of the stem.

What Are Gate Valve Parts?

Many have this question in mind what does a gate valve look like? To get an answer to this it is important to know what are the parts of a gate valve? There are seven main parts of the gate valve. These include Valve Body, Stem, actuator, Bonnet, Flange, and Gate. It is important to know about each of the parts in detail.

The valve body is considered the main part of the valve which holds all the other parts together. Flanges and a gasket connect it to the main piping, moreover, it acts as a boundary for the valve pressure.

The valve bonnet is connected to the valve body through flanges or bolts. It also acts as a boundary for the valve pressure.

The stem, disk, and seat together form the valve trim. The performance of the valve highly depends on the arrangement of the disk and the seat. Moreover, the seat present in the gate valve perfectly fits the disk.

The stem forms a connection between the disk and the actuator. It is mainly responsible for the opening and closing of the seat and disk.

The valve actuator is a wheel-shaped part that helps in the arrangement of the disk and stem.

The different parts might have different designs and applications based on the specific application and design of the valve. Although the designs and applications of the valve and its part might be different its function remains the same.

What Does A Gate Valve Do?

The main gate valve function is to stop, allow or control the flow of fluid passing through. The gate valve is mainly used in stopping and allowing the flow of the liquid. It can be considered an important part of the piping or water system businesses. They are mainly designed for minimizing the pressure while the liquid is flowing through the passage.

Some industries require the flow of a specific fluid for a limited period of time, that’s where the gate valves come into control of the flow of the specified fluidic substances. During the maintenance or repair of the piping systems, the gate valves control the movement of the fluid throughout the pipe system. It is mainly responsible for the isolation of the specific parts in the pipeline where the repair work takes place.

What Are Gate Valve Applications?

The distinct materials, designs, functions, and parts have widened the applications of these valves. As mentioned one of the major applications of this valve is in water treatments. However, other major industries from pharmaceutical, food, gas, and oil to marine, automotive, and many more have different utilization of this valve.

It is not only appropriate for water but also for others such as oil, gas, or steam. Thus, there is a significant application of these valves in petrochemical industries, refineries, and gas processing plants. Furthermore, they are commonly used in high-temperature and high-pressure environments.

The non-stem rising gate valve has its applications in the ship and other underground services. It is also used in limited vertical spaces since these valves do not occupy much of the space.

How Does A Gate Valve Work?

The gate valve working principle is quite simple. Despite the various designs and specifications the working of all the gate valves more or less remains the same. In order to close the valve, the handwheel has to rotate in a clockwise manner. This will lead to a downward movement of the stem and the gate towards the seat located at the bottom of the valve. There is a blockage in the media to prevent leakage. Moreover, it should be noted that not much pressure is applied else it might cause damage to the stem.

On the other hand, to open the valve rotate the handwheel anti-clockwise. Again avoid much pressure to prevent any harm to the disk and seat, further resulting in leakage. In case of higher pressure loosen the nut present above the gate valve. In case there is a requirement for a gate valve for throttling, semi-open the valve, however, be careful there might be a backward flow.

If the valve is completely open, it signifies they are full and the water or any other fluid can pass without any hindrance. This is mainly due to the similar diameters of the gate and pipeline. There is a minimal loss of friction and maximum energy is saved. Moreover, the gate valves are cost-effective with reduced ownership costs.

Gate Valve Installation & Maintenance

If maintained and installed in the correct way can be long-lasting. There might be slightly different installation techniques for different valve designs, however, some of the ways remain the same. The gate valve installation process and maintenance of the gate valve have been discussed below.

Installation Procedure

It is important to keep the gate valve packed until its installation. This will ensure that the seal and seats are protected against the dust or debris that might further result in leakage issues. Moreover, one should also have knowledge about gate valve assembly procedure. The basic process to install the gate valve include the following gate valve installation instructions.

- It is preferable to install the valve, especially the larger ones in an erect position for any easy movement of the handwheel.

- Quick verification of the gate valve parts is important to ensure there is no damage caused during the package and transportation.

- Make sure that all the welding work has been done before installation. Moreover, install the flange only when it has cooled down to a normal temperature.

- Check for any kind of residue or welding debris before installing the pipe. Use a mild detergent for cleaning if required

- Avoid any kind of misalignments of the gate and flange as it is the most commonly occurring installation issue.

- Carefully install the spacing bolts, and pay special attention to the valve seat. Moreover, the flanges are installed in an adjacent manner to provide enough space.

- After centrally installing the pipe, make sure that the bolts rest on top of the valve to keep it from falling through.

- Tighten the bolts with periodic pressure to create a seal between the valve, flanges, and gaskets.

- After the installation, move the valve several times to ensure a smooth movement in the future.

Maintenance of the Gate Valve

There are certain steps to be taken for the gate valve maintenance that has to be followed to maintain its efficiency.

- It is important to periodically add a lubricant to the cavity of the valve. This lubricant acts as a protective layer against contaminants or other fluids.

- The valve should be operated at an appropriate temperature to prevent any kind of physical damage to it.

- Frequent checks are important as there might be high chances of a leak and the most common place for leakage is the packing gland. Tighten the gland nuts in case of a slight leakage.

Gate Valve Packing

The gate valve requires some kind of seal that allows the movement of the stem from an actuator. This seal ensures that no leakage occurs between the valve body and the stem. This sealing mechanism in the gate valve is referred to as Gate Valve Packing. The control valve stem material selection is based on the temperatures.

The valve packing is mainly installed between the stem of the valve and the valve cover packing box to avoid any external leaks. The control valve material determines the performance of the gate valve. One of the main purposes of the valve packing is to prevent leakage in the pipe. The different types of gate valve packing include Flexible graphite packing, PTFE valve packing, Vegetable Fiber valve packing, and asbestos packing.

What To Consider Before Buying Gate Valves?

It is always better to purchase a quality gate valve rather than replace it frequently. Moreover, an inappropriate gate valve can lead to leaks. Thus, ensure to buy the valve that is long-lasting and cost-efficient. Keep these factors in mind while you find the top valve manufacturer that produces high quality gate valve for the business requirement.

Material

The gate valves are available in different materials which determines the longevity of the valve also keep in mind what is the use of gate valve to choose an appropriate material for the valve. Some of the materials that you should refer to for a good gate valve have been mentioned below.

- PVC (Polyvinyl Chloride): PVC is resistant to corrosion therefore, can be used for corrosive media such as acids, seawater, and chloride solutions. Such materials are mainly used in the irrigation system. The maximum temperature of the material is 60 degrees celsius.

- Bronze and Brass: This type of material is appropriate for industries utilizing water, oil, air, or fuel. They have a lesser resistance against corrosion and heat. Their no-resistant property against seawater, and purified water makes them a better choice for small applications utilizing lower pressure.

- Stainless Steel: They are considered the premium material for gate valves due to their high resistant properties. It is resistant to heat, corrosion, and low temperatures. It is not worth purchasing stainless steel if the business does not require high durability and resistance.

- Polypropylene (PP): They have high resistance against inorganic acids and aqueous solutions that can lead to a quick corrosion of the metals. Their maximum temperature is around 80 degrees celsius.

Design

The gate valve can be divided into two parts based on their design- parallel and wedge-shaped. The parallel gate valves consist of a flat gate placed between the two parallelly organized seats. These kinds of valves have a greater application in petroleum, natural gas, and chemical industries. They isolate and transmit the fluid through the pipe system when closed.

The wedge-shaped gate valve consists of mismatched gate inclination and two inclined seats. These valves can seal high as well as low fluid pressure.

Gate valve standard

Each gate valve has a specific standard dimension or a gate valve standard, thus it is important to choose the different gate valve standards before purchase.

ANSI : ANSI A126, ANSI A181, ANSI B16.10, ANSI B16.34 and ANSI B127.1

Uniform Plumbing Code:

The copper alloy should be used for the valves measuring 2 inches (50mm). On the other hand, for the valves measuring more than 2 inches (50mm) cast iron or copper alloy body is approved. The gate and its parts should be created from a corrosion-resistant material. The gate valve utilized for the water management system should follow the guidelines of NSF 61 and ASME A112.4.14, ASME B16.34, ASTMF1970. Furthermore, there should be full-way gate valves for controlling two or more openings.

Underwriters Laboratories (UL):

Specifically designed to meet the standard requirements in UL 262 and FM 1120/1130, UL Gate Valves are available in several types. such as NRS and, OS&Y.

API Standards: API Spec 6D, API Std 594

Gate Valve Sizes

Different types of gate valves have different sizes. One should have a basic knowledge of the gate valve sizes. The primary size range of the gate valves is 50 NB- 500 NB.

OS and Y Type Forged Gate Valve- 15 NB- 300 NB

Rising Stem, Bolted Bonnet, Flexible / Solid Wedge Gate Valves- 50 NB- 500 NB

Working Pressure

Pressure Nominal Classes: The PN class number determines the standard pressure that a gate valve can withstand. There are different bars to measure the pressure and each bar measures 14.5038 pounds of pressure. Thus if the PN class number indicates 3 bars, then the pressure, in that case, would be around 43.5114 pounds.

PSI Rating: PSI or pounds per square inch is considered the standard measurement for pressure. It mainly determines the pressure of the fluid or the gas flowing through the pipe system. A higher PSI rating indicates higher durability of the valve.

Conclusion

The gate valve is an essential mechanical device used in piping systems and other water management systems to avoid the backflow of liquid. This non-return or one-way valve allows the fluid to flow in a single direction and with different principles. It operates by turning the handwheel numerous time, therefore, it works quite slowly.

To get more information about gate valves or to purchase in bulk quantity, you can contact SIO.