Types of ANSI Valve Standards

Share:

Valves are important devices that make it possible for the transportation of liquid-based products like oil from one point to another. With the demand for valves forever rising, a number of companies that specialize in manufacturing and supplying them have cropped up all over the world, and this has necessitated the formation of bodies that ensure there’s a uniform standard across the board that ensures only quality valve products are released into the market. One of those is the American National Standards Institute, better known as ANSI.

We are going to look into the types of ANSI valve standards, the features that define them, and how they affect how liquid materials are transported from one end to another. Stick around to the end if you have been curious about how valves are designed and how they function.

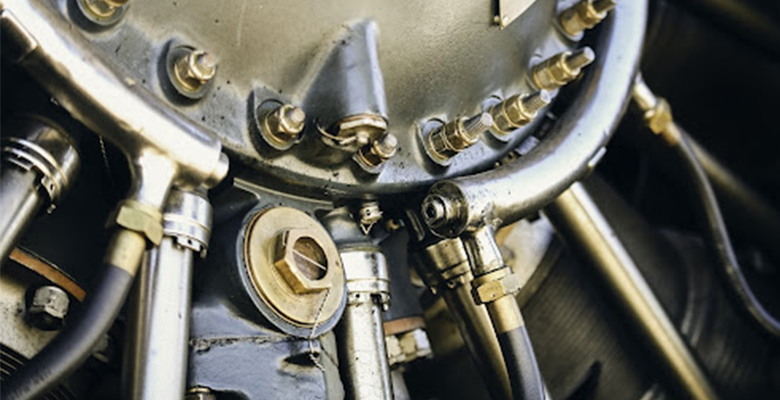

Check Valves

These are ball valves under the ANSI standard 294, and they all feature the same design, like a wafer, butt-weld, and flanged. This ANSI standard provides the consumers with detailed information and insight into the main specifications and precise test requirements, the materials to be used, cover design, pressure ratings, face-to-face dimensions, and other examination requirements.

Some of the benefits of this check valve include the following.

They protect compressors and pumps from any form of damage that can be caused by sudden backflow and reverse flow.

They reduce the downtime and production delays, and losses that can be caused by faulty valve standards.

They regulate pressure drops, and this saves energy.

They are efficient at stopping and eliminating water hammers.

They have lower maintenance costs since they have fewer moving parts.

They leave a smaller footprint compared to other valve standards.

They are highly flexible and can cope with a variety of extreme flow conditions.

They are interchangeable without any need for configuring the entire system.

Metal Plug Valves

Source: Pinterest

These are valves that fall under the ANSI standard 599 and they include welding ends, flanged and threaded types. The details that are associated with this standard range from port linings, skiing, applied hard-facing bottom valves, corresponding pipe sizes, plugs, and body parts. People who are looking to use these valve standards should be aware that it also covers both the lubricated and non-lubricated valves.

The following are some of the benefits of this standard.

They have a solid design that ensures they have the strength to handle any level of pressure.

The body of the valves is constructed using grade II casting and stainless steel, which prevents corrosion, ensuring that the valve stays for very long.

They are covered with bushing, which gives them the ability to withstand high pressure and temperatures of up to 300 degrees.

They can be customized depending on the user’s needs, and this flexibility makes them a better option.

They are able to handle crystallization, viscosity, or any other extreme conditions that are present in the flow processes.

Soft-Seated Quarter Turn Valves

Source: Pinterest

These are valves that fall under the ANSI 607, and they mainly describe the resting requirements for soft-seat quarter-turn valves when they are exposed to fire; these valves come in varying sizes and shapes, but their functioning is gilded by this standard, and this makes them easy to use universally. The following are the benefits of using soft-seated quarter-turn valves.

They are able to be used in the most severe conditions like refining, cement manufacturing, and power generation firms.

They are equipped with a self-lapping technology that rotates itself, polishing the metal seat to keep it clean all through.

They reduce downtimes and are easy to maintain and repair.

They are very durable, with most of them clocking decades before there’s any need for replacement.

Gas Lift Valves

Source: Google

These are valves that are covered under the ANSI standard 11v7. This particular standard provides the consumers with the guidelines for the repair and setting, and resetting of all gas lift valves. It is also a standard that covers the reserves flow valves and how they are applied in their particular areas of use. In a nutshell, these are less compact than most of the other valves as they handle gas flows mostly. Their operations are determined by the preset opening and closing pressures found in the annulus and tubing.

Some of the benefits of this valve standard include the following.

They are solid in terms of construction and can handle high pressures.

They are easy to maintain since they only deal with gasses, and that doesn’t stain them much.

They are durable and can last for years if well taken care of.

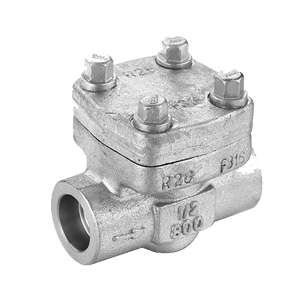

Gate Valves

Source: Pinterest

This is a valve that falls under the ANSI standard of 1600 that governs gate valves in any industry that makes use of them. The standard contains descriptive information like the repair procedures, valve dimensions, inspections, and body wall thickness. This ANSI standard only applies to the gate valves that are used in the natural gas and oil industries, and that means they are well built to handle the intense type of work associated with those industries. The following are some of the benefits of this standard.

They offer the least fluid resistance since the inner media channel is streamlined and straight. There’s no obstruction to the flow.

It is energy-efficient since there’s less power consumption, thanks to the streamlined structure and the easy opening and closing mechanism.

They can allow movement in any direction depending on the settings without reducing the pressure needed to transport the material from one point to another and back.

They have a reliable seal functioning that reduces erosion.

They are easy to operate and maintain and can be handled by just about anyone with basic training.

The Importance of ANSI Standards

Source: www.ansi.org

Industries rely on standardization protocols that are vital in streamlining their operations across the world. This is vital to ensure that each prodigy that they make is able to be used in any part of the world without any compatibility issues. This is why standards like ANSI are in place. The following are some of the reasons why they are important in today’s world.

It promotes uniformity across an industry, and this makes manufacturing and production much easier since the parts needed are standardized and easily available for the parties involved.

It ensures that safety is a priority by imposing strict regulations on manufacturers and suppliers to make sound and solid valves that can handle any kind of work without endangering the lives of other people and consumers.

It helps regulate the pricing of the equipment and the subsequent products within a margin that is uniform across the globe to avoid exploitation of people by some rogue companies.

It brings all the major players in the industry into one roof, and this makes it easy for new innovations and policies to be adopted as fast as possible.

Conclusion

There are many other valve standards that are adopted around the world—each with its own unique regulations and protocols that govern different sectors of different industries. When setting out in any of them, take your time to understand how they operate and the requirements expected of you. For more information on how valves work and the standards applied, check out our website and have all your questions answered by our team of experts.