Industrial valves, through the years, have developed and evolved into various types that serve multiple purposes. One valve type is not like the other – each type of industrial valve has specific characteristics that make it perfect to use in a particular situation. The same is the case with energy valves and their types.

Energy valves have gained a reputation in the industrial industry and are employed widely in other industries. This is because of their special characteristics. Read ahead and find more about the different types of energy control valves and how they are used.

What Is An Energy Valve?

Energy valves are a modernized version of control valves that are employed in heating and cooling applications. Control valves, in general, are used for regulating liquid and gas flow in pipelines. They feature an external operator that helps in controlling the flow of media.

There are two defining characteristics of energy valves that makes them unique compared to other industrial valves. Firstly, these valves are electronically controlled, that is, by an external source of energy. Secondly, energy valves are pressure-independent control valves – they offer two-way pressure control and feature a special technology that enables them to respond to pressure independently.

The technology used in these valves is known as the Coil Optimization Logic – the technology enables energy valves to work and respond without the factor of pressure. Also, these modernized valves are specifically built for the main purpose – to improve water coil performance.

A water coil is a coil that can be of two types – hot and cold coils. Depending on their function, these coils raise or lower the temperature of the airflow perpendicular to the tubes. These coils are made of a culmination of water tubes in the shape of a matrix to enable effective heating or cooling. Special energy valves are capable of even documenting and balancing the performance of water coils.

How Do Energy Control Valves Work?

Energy valves are mainly employed in applications that require a change in the flow of media based on pressure. These valves, combined with the temperature and pressure sensors, work incredibly well to regulate the flow of a medium. The common hardware parts of an energy valve include a temperature sensor, an actuator, a water flow meter, and a 2-way valve disc.

With the help of these components, the energy valve can determine the flow rate of the medium, and adjust the flow as per need. The sensors also help in determining the energy consumed during the flow. As disruptions in the flow of the medium cause several issues, these valves focus on bringing the flow back to regulated conditions.

The 2-way disc present in this specialized control valve ensures that there is no leakage of water – with tight shutting capabilities, these discs focus on keeping the amount of water in the system constant. As for the actuator, it is equipped with advanced software that collects data related to the temperature conditions of the media, the flow rate, and the amount of energy consumed.

The working principle of an energy valve is quite simple – when it detects a change in the pressure and rate of flow in the system, it works to bring things to order. As a reaction to the pressure change, the valve alters the flow until the required rate of flow is required.

Energy Valves for Heating Applications

While energy valves have a common working principle, they have slight changes in how they work depending on their specific applications. In heating appliances, the main goal of the system is to maintain the temperature or to raise the temperature to the desired level.

So, when the temperature sensors in the energy valve detect a lower differential temperature across the coil, it begins to close. This leads to the rate of flow reduction – now, the system will be able to make up for the heat loss and avoid overflow. Once the required temperature is achieved, the flow gets back to normal as the valve opens.

Energy Valves for Cooling Applications

The working principle here is somewhat similar to that of the above-mentioned one. When the temperature inside the system and valve dips below the desired one, the valve begins to close, thus reducing flow. When the flow is less, the system makes up for the energy loss and establishes the required temperature. Then, the flow begins once again.

What Are The Different Types Of Energy Valves?

Energy valves are of different types based on the applications they are used for. While the basic design and working principle of these valves are the same, they are designed with special elements for specific applications.

On the other hand, industrial valves used in the energy sector are of various types. From gate valves to check valves, there are different types of industrial valves used in the energy production industries. Some common industrial valves used in this sector are pressure seal gate valves, globe valves, and check valves.

Pressure Seal Gate Valves

Gate valves feature a gate-like structure that starts or stops the flow of a medium. While these valves are not suitable for throttling or controlling purposes, they can be used for the isolation of one media from another.

Pressure seal gate valves are specifically used in high-pressure situations like in energy power plants. As the internal pressure in the valve increases, the seal of the gate valve tightens. These types of valves are suitable to use in situations above 100 bar.

Pressure Seal Globe Valves

A globe-like disc is present in these globe valves that help in stopping and resuming the media flow in a system. This disc can also be used for throttling the media. Unlike gate valves, these valves are primarily used for throttling purposes.

In the energy production industries, these valves are used for the regulation of media in power plants. As they have a simple design and are easy to maintain, they are preferred over other industrial valves. Also, these valves create low friction which extends their lives.

Pressure Seal Check Valves

Check valves ensure that the media in a system does not flow back. These valves are unidirectional and prevent backflow. The design of pressure seal check valves ensure that there is a low-pressure drop across the system.

Backflow can be a hazardous condition, especially in power plants, and these check valves ensure the prevention of backflow. Because of their function, these valves face a lot of damage in their lifetime.

What are Geothermal Valve Types?

With the need for renewable energy resources on the rise all over the world, different types of power plants are being built for improving energy production. Geothermal energy is one of the most abundant sources of energy, and several nations are relying on it. There are three types of sources for this energy – flash steam, dry steam, and binary cycle.

In geothermal power plants, industrial valves find a wide range of applications. Geothermal valves can be of different types – globe valves, butterfly valves, and ball valves are some of the common types used in this industry. In industries such as these, there arises a requirement where the valves need to handle fluids of very high temperatures. Choosing the right valves is important when it comes to industrial purposes such as these.

Butterfly Valves

Butterfly valves are widely employed in geothermal power plants. While older designs faced issues of scaling, where sediments settled on the inside of the piping system, newer designs and versions of the valves are used for a seamless experience. Butterfly geothermal valves are usually preferred because of their tight sealing capabilities. These valves are also efficient when it comes to stopping the flow of a medium.

Globe Valves

Control valves, like energy and globe valves, play a crucial role in the power plant industry. Regulating media is crucial in power plants, and as a control valve, the globe valve is very precise in maintaining the flow. They are high-performance valves that can sometimes be operated with electric actuators – globe valves are also capable of collecting when they are equipped with sensors.

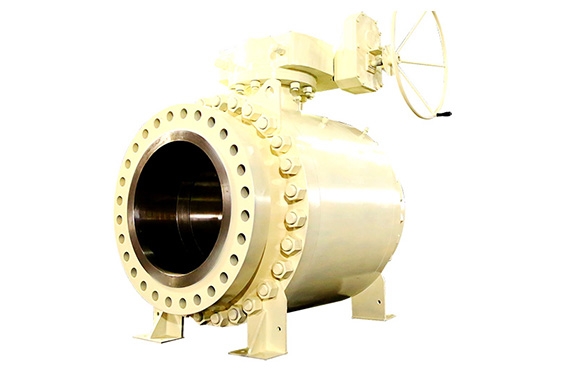

Ball Valves

Be it for tight shut-off, or for regulation, ball valves act as a great option in both cases. These geothermal valves are highly efficient and are suitable for tight sealing. Newly developed technology in ball valves ensures that there is no scaling when used in power plants. These valves operate smoothly and last long.

What is a Solar Valve?

A solar valve is a special type of valve that automatically shuts off the flow of gas when there is daylight. It is an automatic control valve that gained appreciation during the time of its invention. Due to the heat of the sunlight, a dark rod present inside the valve expands and cuts off the gas flow.

On the other hand, valves that are used in solar power plants can also be understood as solar valves. These valves include ball valves, check valves, and control valves.

Ball Valves in Solar Application

Metal-seated ball valves are used wherever there arises a need for handling high temperatures. These valves belong to the quarter-turn family, and they are specifically designed to handle the “turn on and off” capabilities. All valves experience lesser seat wear compared to other valves.

Check Valves in Solar Application

Non-return valves are crucial in any power plant, and the same applies to the solar industry. These valves ensure that the media in the pipelines do not experience backflow. These valves are perfect for stopping the flow of any medium at a given point in time.

Control Valves in Solar Application

Control valves, like energy valves, can be of great importance in the energy production industry. By keeping a check on the flow of media, these valves ensure that the pressure and temperature of a given medium do not change and cause accidents.

Factors to Consider when Selecting Energy Control Valve

Generally, there are a few things one must keep in mind while choosing a valve. They are:

- Valve Function – Valves serve a variety of functions – ranging from shut-off capabilities to preventing backflow, one can opt for a valve based on its main function. In the case of energy control valves, they are mainly used for regulating media in a system while ensuring that pressure does not build up.

- Application Conditions – In the case of energy production power plants, the working conditions for industrial valves will consist of high temperatures and pressure ratings.

- Media Type – The media that the valve is about to carry is an important consideration before choosing a valve. Based on the viscosity and strength of the medium, the valve needs to be chosen.

- Actuation Method – Some valves are automatically actuated while the others need an actuator. Ensure the type of actuation the application requires and then choose the valve.

Contact Industrial Valve Manufacturer to get Energy Valve

Finding a high-quality industrial valve manufacturer might be a tough task. Not every manufacturer is an expert in this field like SIO valves – with over 10 years of experience, we are one of the top industrial valve manufacturers in China. Get in touch with us today and find a wide range of energy valves that are suitable for your required applications.