Gas Process Refinery Valves

Comprehensive types of valves used in refinery, SIO manufactures high- performance petroleum valves and refining valves.

Get Refinery & Petroleum valves from a Reliable Manufacturer

Fire safety is crucial in oil refinery plants and other alternatives like storage terminals and chemical processing industries. For this, temperature-controlled well-built valves are sustainable options, and that is what we at SIO offer. Our refining valves are made of high-quality material and technology, and we have tested our products for reliable automation processing.

Throughout the oil refining process, our refining valve solutions would safely and productively give the necessary support. We check and meet the strict industry standards and supply full-coverage refinery valves.

Valves suited for the gas process & refinery application

At SIO, we have a history of providing high-quality components and machinery that boost gas processes and refining systems to high measures. Our petroleum valves and other varieties support the functions well. Below are some types of valves used in refinery.

High-performance butterfly valve

The high-performance butterfly valve closes off the flow of the liquid effectively, ensuring the smooth functioning of the procedure. The seat-on type of disc design is helpful for proper field replacement and adjustment without any extra epoxy or special tools usage.

- The wafer design extends between 4" - 12" in most models.

- Have a high-pressure control limit.

Control Valve

This temperature control valve effectively stops the high petroleum and oil heating flow through the mechanism, ensuring a safe and tight seal. They can also be used in cogeneration systems to control temperatures in heat recovery loops, ensure proper engine cooling and maximize heat recovery.

- Its prime benefit is to regulate temperature control throughout the heating process.

- Suitable for process control applications where fluids are mixed or transferred to achieve optimum temperatures.

Pressure Relief Valve

The temperature-pressure relief valve helps handle the oil refinery process’s high pressure and temperature output standard. The prime benefit of this valve is maintaining the overall safety of the machinery by regulating the pressure-flow throughout the process.

- More straightforward design and operation.

- Allow for tight shut-off mechanism.

- This tight shut-off valve doesn’t get blocked no matter what type of media.

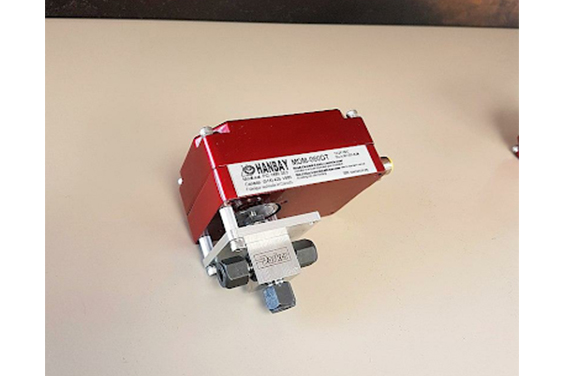

Ball valve

The diesel fuel ball valves regulate the flow of high-pressure gasses and liquids with a minimal pressure drop. Refinery valves lend the ability to be used in various locations apart from gas process and refinery plants.

- Easy to install and operate in complex locations.

- Tight seals with low torque and can be opened and closed quickly.

Why choose a refinery valve from a professional manufacturer

At SIO, our solutions are top-quality, and our types of valves used in refinery processes are well-tested. We carefully check out all of the products we provide in terms of build, functionality, and specifications before supplying.

Certificates

We follow the needs of the industry well and focus on offering certified solutions only. We provide ISO industry-standard approved models only to our clients.

Variety

One of the best quality benefits you can expect is that we offer different valves used in the refinery.

High Performance/Quality

Quality is a priority for us, and we offer that as a guarantee with our diverse solutions. We carefully evaluate the refinery valves for high precision before supplying them to our clients.

The ability to deal with refinery application

Gas and oil refinery methods quality valve items that can work fast and handle robust processing well. That we do offer with our products.

Support

The valves we offer can withstand large-scale power plants' various pressure and temperature needs. Our professionals are there to provide additional assistance whenever necessary.

Meet business requirements

We support our clients with the objectives they require from the machinery and processes and offer solutions that would allow you to gain high profits in the industry.