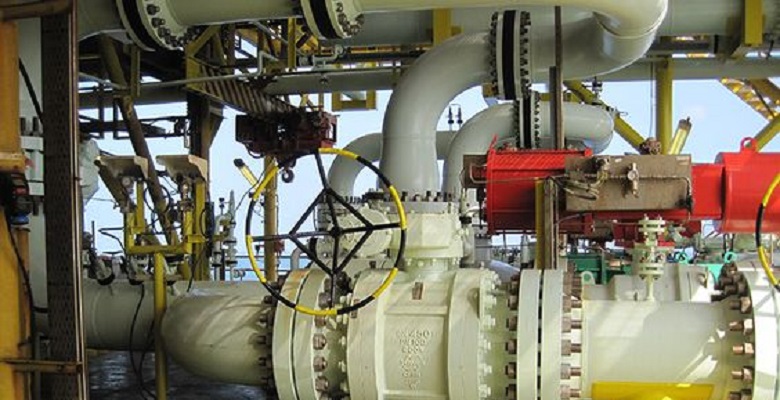

1. Ball Valve

Pneumatic actuated ball valves control the flow of fluid through compressed air from one opening to the next using a ball. In the center of the ball, there is a port which is popularly known as the bore. One of the features of a ball valve is that it can be opened and closed easily. When the valve is open, and the bore is aligned with the pipeline opening, the fluid passes through the valve. The bore is then placed in a perpendicular position with the pipeline opening once the valve is closed since it blocks the flow of the fluid from passing through.

A pneumatic ball valve is easy to operate. It has an airtight seal whenever it is closed, making it a reliable and durable choice for pipeline and gas applications where tight shutoff is essential. It is also an ideal valve for transmission and storage, chemical, pharmaceutical, and oil processes.