Butterfly Valves

Products Portfolio

By Type

By Design

By Material

By Actuator

By Industries

- Slurry Valves

- Water Treatment & Wastewater Valves

- Natural Gas Valve

- Chemical&Petrochemical

- Geothermal Energy

- Gas Process & Refinery

- Pulp and Paper Valves

- Mining Valves

Assessories

Butterfly Valves

SIO makes top-quality butterfly valves using different materials and configurations. Butterfly valves are a 90 degree-turn rotational valve that is useful in stopping, regulating, and starting flow. They’re easy and quick to open as the quarter rotation allows the entire closing and opening of the valves.

They are a popular choice because of their thin feature between the flanges, which makes them lightweight and affordable. Most large butterfly valves will come with a “gearbox,” which makes the application of the valve easy to operate. However, this will affect the speed of the operation.

AT SIO, you can be confident that we will see to it that you only get the best butterfly valves for your projects.

Butterfly Valve Manufacturer

Butterfly valves function as regulatory or shut-off valves. They are operated in a quarter-turn rotational motion to regulate, start, and stop the fluid flow. They limit the flow by being partially open, or they can entirely shut off the flow. Butterfly valves are best suitable for shutting off and throttling processes.

As a butterfly valve supplier, butterfly valves are maunfactured to control the flow rate of a fluid. The type of fluid varies on what materials butterfly valves are made of. They can be chemically neutral fluids, pharmaceutical fluids, or even corrosive fluids. These valves are the best choice in cooling water, gases, air, and fire protection systems, and vacuum and steam services.

Butterfly valves have a good sealing system which is suitable for heating circuits. Some butterfly valves are equipped with flanges, they are essential in pressure drop.

Metal Seated Ball Valves Features

Temperature range

The SIO valves have a wide temperature range. They can resist temperatures from -4 degrees Fahrenheit to 260 degrees Fahrenheit.

Body Material

The SIO valves can be made with different body materials, including stainless steel, carbon steel, nickel alloy steel, nickel aluminum bronze, titanium and titanium alloys, cast iron, and ductile iron.

Diameters

When it comes to the diameter of SIO valves, it varies from one model to another model. Depending on the application, you can choose from valves with 2″ to 24″

Fluid regulation

The SIO valves can regulate the flow of slurry as well as compressed gas. The corrosion resistance is different for a pfa lined butterfly valve and others.

Benefits of using Butterfly Valves

Manufactured by a reliable and experienced butterfly valve supplier, the quality and price of butterfly valve could be guaranteed for our customers.

Cost-effective

If you compare butterfly valves to other types of valves for fluid flow regulation, they are comparatively easy to manufacture without being expensive.

Easy Maintenance

Along with being compact in design, butterfly valves are very easy to handle and manage. The maintenance costs with teflon lined butterfly valves are significantly reduced due to the reliable construction of a butterfly valve. The abrasion free nature of these metal seated butterfly valves helps any plant owner to save costs.

Less Structural Support

Butterfly valves are comparatively light and require less structural support than any other kind of valve vene if the diameter is the same. This makes it one of the most preferable valve types on the market.

Standard and Specification of Butterfly Valves

Pressure Range

Wide Temperature Standard

End Connections

Low maintenance

Common Metal Seated Ball Valve Applications

Steam service

Gas service

High temperature service

Vacuum service

High pressure service

Butterfly Valve from China

The primary consideration with butterfly valves is how they are manufactured. SIO’s factory and facilities are capable of manufacturing butterfly valves that can withstand high pressure and temperature conditions.

If you want a wholesale manufacturer from China for quality butterfly valves, our facilities ensure that the production is on time every time. The high precision equipment used in the manufacturing of butterfly valves helps in the making of cost effective products, even in bulk.

What Are the Components of a Butterfly Valve?

Body

The body of butterfly valves fits between two flanges, and the common designs are lug and wafer. The lug body provides bolts to match those in the pipe flange using protruding legs, while the wafer body is positioned between two flanges using nuts and studs or bolts. Unlike the lug body, the wafer body does not have protruding legs and are more economical in initial and installation costs.

Seat

Most butterfly valves utilize an elastomeric seat and the disc seals against it. The seat provides shutoff using an interference fit connected to the disc edge. When the disc is sealed against a seat inside the valve body, the flow of fluid stops. The seat can either be locked in or pressed inside the body.

These designs increase the pressure in the pipeline, adding more interference between the disc edge and seat. The seat has different temperature and compatibility variations depending on the material used for the construction.

Stem

The stem of a butterfly valve varies in design. It can come in a split-design, a one-piece or two-piece shaft. The stem gives the strength required to unseat or seat the disc, so the position the stem should be accurate. Since it has a close contact with the media, the stem should be compatible with the fluid.

Disc

The disc is designed to close the valve and stop the flow of liquid, playing a role similar to the ball in a ball valve, the plug in a plug valve, and the gate in a gate valve. Besides, the disc regulates the fluids like water and chemicals.

The disc is aligned with the stem, which improves the flow of fluid, sealing and operating torque. The disc closes or opens the valve through a 90-degree rotation.

What Are the Different Types of Butterfly Valves?

Butterfly Valves by Valve Body Material

Carbon Steel butterfly valves

Carbon steel butterfly valves are characterized by their strength and durability. Because they are primarily used for low pressure systems they can work well in the chemical, food and Pharmaceutical industries.

Stainless Steel butterfly valves

Stainless steel butterfly valves are composed of iron, nickel and 10.5% chromium. The use of chromium in the manufacturing process adds an additional layer of oxide to prevent rusting and corrosion from exposure to toxic media.

Nickel Alloy Steel

A nickel alloy steel butterfly valve is made for all the industries where fluid will be highly corrosive. The facilities will offer challenges in terms of high pressure and temperature conditions.

Titanium and Titanium Alloy Butterfly Valves

Titanium boys and titanium alloy material is the most preferable when it comes to strength-to-weight ratio. The oxide layer in these valves prevents any rusting which can be seen in valves made of other base materials.

Nickel Aluminum Bronze

The nickel aluminum bronze alloy features 5% nickel, 5% iron, and 10% aluminum which helps improve the resistance and strength of the material. They prevent biofilm which is the primary cause of corrosion in valves.

Ductile Iron

The most notable benefit of ductile iron butterfly valves is that they are extremely well equipped to handle harsh conditions and have a high tensile strength. They are resistant to high pressure and corrosive media which makes them well equipped for different industries.

Cast Iron

A cast iron butterfly valve has added strength because it is actually in an alloy of silicon, iron and carbon. They are perfect for industrial systems with high pressure and temperature conditions. They also have impressive shock absorbance.

Butterfly Valves by Design / Disc Alignment

The design of the valve will vary based on the type of disk used as well as the number of stems. Both two piece and one piece shaft designs are used for industrial applications and account for different types of butterfly valves.

Concentric / Zero Offset

In a concentric or zero offset butterfly valve, the center of rotation is focused and the middle of the desk and every process is streamlined at the center. They're more popularly used in soft seated valves with low pressure systems.

Double Eccentric / Double Offset

Also known as high-performance butterfly valves, double eccentric or double offset walls are commonly used in high-pressure and temperature situations and systems across different industries. Double eccentric valves are used in power generation, oil and gas industries to prevent jamming.

Triple Eccentric / Triple Offset

Used mainly in power generation operations and pharmaceutical industries. , triple eccentric butterfly valves have uniform sealing a 90-degree rotation to prevent leakage and facilitate easy regulation of media.

Butterfly Valves by Sealing Material

Rubber Lined Butterfly Valves

Rubber Lined Butterfly valves are constructed to be utilized for separating or controlling flow with rubber as the primary sealing substance. The valves are light in weight and their discs relatively induce a pressure drop.

Plastic Lined Butterfly Valves

The rubber lined butterfly valves are also light in weight and free of maintenance, and act as heavy-duty solutions to applications that handle high pressure. For example, they are suitable for petrochemical processing, paper industry, and fuel handling systems.

Metal Lined Butterfly Valves

These valves retain a metal to metal sealing, which provides the power to resist elevated pressure and weather circumstances. Because of their wear resistance and durability, they are suitable to be used in fuel, petroleum, and food industries.

Butterfly Valves by End Connection Type

Different types of butterfly valves can be classified based on their end connections which help classify them as per their industrial applications. Butterfly valves have flanged ends, lug type ends, wafer type ends, and butt-welded type ends.

Wafer Type

Wafer type butterfly valves are the best option for use across different industries. The tight sealing feature helps create a strong blocking point which does not allow any block backflow even in case on bi-directional media flow.

Lug Type

Lug type butterfly valves are characterized by using different sets of bolts to attach different flanges. In an industry where downstream piping service is to be removed when relying on using lug type valves.

Flanged Type

Iceland guide butterfly valve has a flange face on both the sides and is often used for heavy-duty applications. Irish temperature in pressure conditions will not impact the performance of this particular butterfly valve.

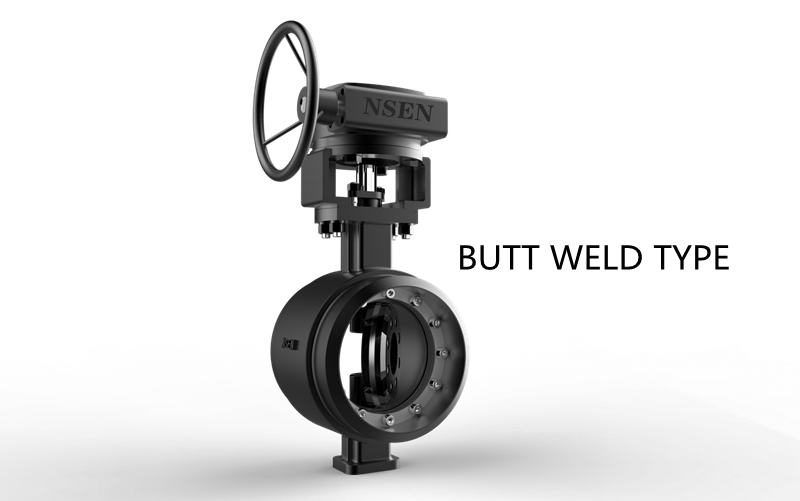

Butt Welded Type

This type of butterfly valve is known to prevent scratching in the internet parts and tolerate high pressure and temperature fluids. They are used mainly in the petrochemical and power generation industry.

Butterfly Valves by Seat Type

The walls may have a locked, pressed, or bonded seat. A metal seat butterfly valve will have different features than a soft seated one.

Metal Seated Butterfly Valve

Between the body and the flavor of metal seated butterfly valves use a sealing surface made of metal. They have a wide range of applications across different industries as they can tolerate harsh conditions related to temperature and pressure.

Soft or Resilient Seated Butterfly Valve

For all industries with less critical applications and low pressure systems resilient seated butterfly valves come in handy. Used in the pharmaceutical industry and food production valves come with a quarter turn rotation.

Butterfly Valves by Valve Operation

The valve operation of butterfly valves makes it easy for the controller to manually or remotely access and control the media in a large facility. Different types of butterfly valves are operated differently, but mostly they operate like quarter-turn valves.

Manual Butterfly Valve

Manual butterfly valves are of two types: lever handle and gear butterfly valves but the basic process of usage remains the same. Manual operating valves are used in smaller spaces and with smaller systems to effectively regulate media flow.

Automatic Butterfly Valve

Automatic butterfly balls are characterized by a remote control of media flow. Almost all automatic involves manual levers as a failsafe method. Automatic butterfly balls out of 3 types: electric, pneumatic and hydraulic.

Three Types of Actuated Buttefly Valve

Pneumatic Actuated Butterfly Valve

Pneumatic actuated butterfly valves convert an air signal into valve stem motion through the air pressure in a diaphragm or piston which is connected to the stem. Pneumatic butterfly valves are suitable for open-close positioning and throttling operations since they are considered fast-acting valves.

Electric Actuated Butterfly Valve

Electric actuated butterfly valves may have an automatic, semi-automatic, or manual operation. Electric actuators are one of the most common types of actuators in butterfly valves because they are maintenance-free and reliable. These actuators allow electric actuated butterfly valves to be operated remotely.

Hydraulic Actuated Butterfly Valve

Hydraulic actuated butterfly valves are designed to regulate the flow of hydraulic fluid in a hydraulic circuit. Hydraulic actuators are often used to open a valve which requires a large force. They are utilized to redirect pressurized fluid or completely close a line.

Butterfly Valve Manufacturer

Butterfly valves function as regulatory or shut-off valves. They are operated in a quarter-turn rotational motion to regulate, start, and stop the fluid flow. They limit the flow by being partially open, or they can entirely shut off the flow. Butterfly valves are best suitable for shutting off and throttling processes.

Butterfly valves are designed to control the flow rate of a fluid. The type of fluid varies on what materials butterfly valves are made of. They can be chemically neutral fluids, pharmaceutical fluids, or even corrosive fluids. Butterfly valves have a good sealing system which is suitable for heating circuits.

Butterfly valves have a disc mounted on a rotating shaft. The disc forms a right angle to the flow of the fluid when the valve opens. When the valve is fully closed, the disc blocks the line completely, which disrupts the flow.

Butterfly valves help in decreasing pressure in a system as they control the flow of the fluid. Once the

fluid passing through the valve’s opening is restricted, the pressure drops significantly further down the pipeline. Some types of butterfly valves, like PVC butterfly valves, have a handle that stops and locks at any position as it fully opens or closes to control the flow of the fluid with precision.

Some butterfly valves are equipped with flanges, which means they cannot be attached to piping right away. They are essential in pressure drop since the valve disc is always present amid flow. Butterfly valves are used for different fluid services and in slurry applications. These valves are the best choice in cooling water, gases, air, and fire protection systems, and vacuum and steam services.

What Are the Components of a Butterfly Valve?

Body

The body of butterfly valves fits between two flanges, and the common designs are lug and wafer. The lug body provides bolts to match those in the pipe flange using protruding legs, while the wafer body is positioned between two flanges using nuts and studs or bolts. Unlike the lug body, the wafer body does not have protruding legs and are more economical in initial and installation costs.

Seat

Most butterfly valves utilize an elastomeric seat and the disc seals against it. The seat provides shutoff using an interference fit connected to the disc edge. When the disc is sealed against a seat inside the valve body, the flow of fluid stops. The seat can either be locked in or pressed inside the body.

In high-performance designs, the shutoff can be provided by a line-energized seat design or an interference-fit design. These designs increase the pressure in the pipeline, adding more interference between the disc edge and seat. The seat has different temperature and compatibility variations depending on the material used for the construction.

Stem

The stem of a butterfly valve varies in design. It can come in a split-design, a one-piece or two-piece shaft. The stem gives the strength required to unseat or seat the disc, so the position the stem should be accurate. Since it has a close contact with the media, the stem should be compatible with the fluid.

Disc

The disc is designed to close the valve and stop the flow of liquid, playing a role similar to the ball in a ball valve, the plug in a plug valve, and the gate in a gate valve. Besides, the disc regulates the fluids like water and chemicals.

The disc is aligned with the stem, which improves the flow of fluid, sealing and operating torque. The disc closes or opens the valve through a 90-degree rotation.

What Are the Different Types of Butterfly Valves?

Butterfly Valves by Valve Body Material

Source: Indiamart

Carbon Steel

Carbon steel is an alloy of iron where the main element is carbon. Carbon steel butterfly valves are affordable and useful for low-pressure applications. These valves are highly suitable for food, oil and gas, chemical, and pharmaceutical industries.

Carbon steel butterfly valves come in several different grades. These grades are cast grades ASTM A216 WCB or Weldable Cast B-grade, which are great for high-temperature applications, and LCC or Low Carbon Content steels, which are most suitable for low or sub-zero temperatures.

Stainless Steel

Stainless steel is made from an alloy of iron and nickel with 10.5% of chromium content. The addition of chromium forms a self-healing layer of oxide on the material which prevents it from rusting. The common classifications of stainless steel are ferritic, martensitic, precipitation hardenable, duplex, and austenitic. However, when it comes to valve construction, duplex and austenitic stainless steels are the most commonly used materials.

When the surface of stainless steel butterfly valves is scratched, the chromium reacts with oxygen, which in turn stops the surface from reacting with iron and prevents rusting. Therefore, stainless steel butterfly valves are highly recommended in applications that require high corrosion resistance, such as water systems.

Source: Indiamart

Nickel Alloy Steel

Nickel alloy steel butterfly valves are often used in severe and harsh conditions in terms of temperature, pressure, and fluid. They are designed to withstand highly corrosive environments, which are not recommended for lower grade steels, such as stainless steel materials. Extreme corrosive environments may wear down the protective oxide layer stainless steel valves have.

Source: Alibaba

Titanium and Titanium Alloys

Titanium butterfly valves are known for their excellent corrosion resistance and remarkable strength. Compared to other metals, titanium alloys have the highest strength-to-weight ratio. These materials also have a protective oxide layer found in stainless steel valves, which protects the valves from rust.

Titanium butterfly valves boast on its durability as it can withstand corrosive environments, such as seawater and industries operating with hypochlorite.

Nickel Aluminum Bronze

Nickel aluminum bronze butterfly valves are made from a copper alloy which has approximately 5% nickel, 5% iron, and 10% aluminum. They are highly resistant to corrosion and are much more suitable for seawater applications. These nickel aluminum bronze butterfly valves can prevent biofilm, one of the causes of corrosion problems among stainless, from forming.

Source: Engineering 360

Ductile Iron

Ductile iron butterfly valves are made from a modern iron alloy which is manufactured with nodule-shaped graphite. These valves have an excellent ductility, which means that it does not break easily when bent. Ductile iron butterfly valves boast on its remarkable tensile and yield strength and their high resistance to corrosion.

Ductile iron butterfly valves have impressive structural integrity, which means that these valves can handle high temperatures and pressures without making a flinch. Because of their ductile nature, these valves do not crack easily even when bent.

Source: Indiamart

Cast Iron

Cast iron butterfly valves are made from a type of metal that has been utilized for hundreds of years now. These valves came from an alloy made of small amounts of silicone, 2 to 4% of carbon and 96 to 98% of iron, which gives cast iron butterfly valves their impressive temperature tolerance.

Cast iron butterfly valves are remarkably strong because they usually remain undamaged after experiencing intense vibrations during operations. These valves can deal with higher pressures compared to any plastic.

Butterfly Valves by Design / Disc Alignment

Concentric / Zero Offset

Centric or concentric butterfly valves are the most basic types of butterfly valve design. In concentric butterfly valves, the center of rotation is at the centerline of the valve disc which is located in the center of the bore. The seat is inside the diameter periphery of the valve body.

A concentric butterfly valve has a conically-designed frictional interference seal between the seat and the seal which is located at the center. This design is best applied in soft seated valves as they rely on the flexibility of the seat rubber to seal the flow of fluid efficiently when the valve is closed.

In concentric butterfly valves, the media that passes through the valve will not come in contact with the body since the seat is constructed as a sleeve in the valve body. The disc comes in contact with the seat first at around 85 degrees when a quarter-turn rotation is taking place. Zero offset butterfly valves are best used in low-pressure applications.

Double Eccentric / Double Offset

Also known as high-performance butterfly valves, double eccentric butterfly valves are commonly used in power generation, chemical, HVAC, and oil and gas industries. Compared to zero offset or concentric butterfly valves, double eccentric valves can withstand higher pressure and temperature conditions.

The double offset butterfly valves have two stems offset from the center, which are responsible for creating a cam action during the application process. In double offset butterfly valves, the sealing plane of the disc is offset from the axis of rotation. Because of the position of the sealing plane which leads to a circular sealing surface on the disc, an annular sealing element can be placed in the valve. The axis of rotation of the disc is positioned at the side of the center so it can move freely from the seat to prevent the valve from jamming as it opens and closes.

Double eccentric butterfly valves remove wear points at the top and bottom of the seat and around the disc, extending the duration of the valve’s leak-free performance. Seats are generally available in plastic or metal materials.

Source: Crane Engineering

Triple Eccentric / Triple Offset

Also called triple offset butterfly valves, triple eccentric butterfly valves have three offsets. Two of them are located in the same position as the double offset butterfly valve. The third offset, on the other hand, is geometrically placed to the seating surface, which creates a cone-shaped angle of the seat and disc. These three eccentric shaft offsets make a seal between the disc and the seat with no friction.

Triple eccentric butterfly valves have a tight shutoff and a uniform sealing. These valves are designed to have easier automation at a very affordable cost, which is an alternative for metal seated valves.

Generally used in applications where a metal seat is required and a 90-degree rotation and tight shutoff are preferred, triple eccentric butterfly valves are best suitable for high-temperature gases and oils and high-pressure steam. These valves are needed in demanding operations, such as petrochemical and power generation industries.

Butterfly Valves by Sealing Material

Source: Indiamart

Rubber Lined Butterfly Valves

Rubber lined butterfly valves are designed to be used for isolating or regulating flow with the use of rubber as the sealing material. The closing mechanism is the disc that sits in the center of the valve body and is connected to an actuator or handle through a shaft that passes through the top of the body for the disc. Compared to a ball valve, the disc of a rubber lined butterfly valves induce a pressure drop since it is always present in the flow. Because they are lightweight, rubber-lined butterfly valves can be shut off easily without requiring too much support, unlike ball valves.

Rubber lined butterfly valves are fully operated in a 90-degree rotation motion. In order to throttle flow, these valves can also be opened incrementally. Throttle flow can be done by manual rubber lined butterfly valves, but actuated rubber lined butterfly valves give more precision.

Rubber lined butterfly valves are lightweight valves that provide lower cost, maintenance-free, and heavy-duty solution to high-pressure applications, such as pulp and paper industry, fuel handling systems, petrochemical processing, and HVAC operations.

Plastic Lined Butterfly Valves

Using a plastic sealing material, plastic-lined butterfly valves are used to regulate, stop, and start the flow of fluid. They are great with on and off operations, throttling, and control applications for powdery media, liquid, or gaseous service.

Source: Garlock

Metal Lined Butterfly Valves

Metal lined butterfly valves have a metal to metal sealing, which gives these valves the capacity to withstand high pressure and temperature conditions. With their stable sealing performance, metal-lined butterfly valves are durable and wear-resistant. These valves are designed to be used in various applications, such as operations in the petroleum, fuel, and food industries and those systems requiring high fire resistance.

Butterfly Valves by End Connection Type

Source: Indiamart

Wafer Type

Often considered as the lightest and cheapest option in choosing butterfly valves, wafer type butterfly valves are installed with two or more centering holes. Wafer butterfly valves are designed to retain a seal to protect the valve from dual-directional pressure differential in the fluid flow. To make it simpler, wafer butterfly valves prevent backflow in the systems by holding a tight seal to prevent the bi-directional pressure differential from entering the valve.

To safeguard the systems from the bi-directional pressure differential, a tightly fitted seal, such as a gasket, O-ring, precision machined, along with a flat valve face on the upstream and downstream areas of the valve.

Lug Type

Lug type butterfly valves connect with pipe flanges by using a separate set of bolts for each flange. These valves are designed like a 3-piece ball valve, which means that when one end of the line is taken off, there is no effect on the opposite side of the line. Lug butterfly valves allow the removal of downstream piping or dead-end service.

Source: Indiamart

Source: Garlock

Flanged Type

Flanged type butterfly valves have a flanged face on both sides of the valve. These valves are commonly large in size. Known for its flawless and hassle-free performance, flanged type butterfly valves are used for heavy-duty applications and can withstand harsh environments, such as water desalination plants. These valves have a distinct stem retention design to check and regulate the flow of fluids for different applications efficiently.

Butt Welded Type

Butt-welded butterfly valves are uniquely designed to prevent scratches and to gall between the metal disc and metal seat. The seal only comes into contact with the seat once, which is during the valve is completely closed.

Welded type butterfly valves are widely used in applications that require very high pressures and those that require bi-directional tight shutoff, such as petroleum, chemical, and power generation industries. These types of valves are also designed to prevent extrusion in dirty or heavy oil.

Source: Pinterest

Butterfly Valves by Seat Type

Source: Alibaba

Metal Seated Butterfly Valve

Metal seated butterfly valves use metal for the sealing surface between the body and the flap; hence, the name of the valve. A special thin seal can be used in the body of the metal seated butterfly valves to improve the tightness and reduce the temperature resistance. Since these valves have a higher resistance in high pressure and temperature, their applications are more extensive compared to the soft seated butterfly valve.

Metal seated butterfly valves are widely used in industries that are under extreme temperatures and pressure. To be able to withstand harsh environments, the metal seats are manufactured to add more durability and versatility to the valves. Metal seated butterfly valves are very popular for their system compatibility and general make up.

Soft or Resilient Seated Butterfly Valve

Primarily used to regulate, stop, and start the flow of fluid in pipelines, soft or resilient seated butterfly valves are highly suitable for low pressure and non-critical applications, such as food and pharmaceutical industries. These valves can be operated by gears, handles, or actuators.

In this type of valve, the stem is at the center of the valve disc, which is placed at the center of the pipe bore. Resilient seated butterfly valves move the valve disc into the optimal position to close or open the valve completely. These valves typically have a rubber or a resilient seat which significantly relies on the contact between the disc and the seat to provide a tight seal, which usually happens at around 85 degrees during a quarter-turn rotation.

Butterfly Valves by Valve Operation

Manual Butterfly Valve

Manual operated actuators use a crank or a handwheel to close or open the valve. These actuators give the user the ability to position the valve as necessary. Butterfly valves that are manually operated are great for remote systems have no access to power. Manual actuators are more recommended on smaller valves.

In manual actuated butterfly valves, the handwheel is fixed to a stem or hammer to allow the valve to be pounded closed or open when needed. For additional mechanical advantage, gear heads are added to increase open and close speed.

Lever Handle

Small butterfly valves commonly use lever handle actuators. These actuators can lock valves into an open, partially open, or closed position.

Gear Handle

Gear handle actuators are designed to be used by slightly larger butterfly valves. Butterfly valves with a gear handle decrease the speed in opening and closing the valve to increase the torque using a gearbox. Gear actuated butterfly valves are equipped with position indicators and are self-locking valves.

Automatic Butterfly Valve

Automatic operated actuators are used in controlling valves remotely. These actuators allow the rapid operation of larger valves.

The designs of power operated actuators are fail-open or stay open when there is actuator failure, fail-close or stay closed when the actuator fails, often comes with a manual actuation method when the actuator fails. The three types of automatic actuators are electric, pneumatic, and hydraulic.

Source: Indiamart

Pneumatic Actuated Butterfly Valve

Pneumatic actuated butterfly valves can either be semi-automatic or automatic. They convert an air signal into valve stem motion through the air pressure in a diaphragm or piston which is connected to the stem. Pneumatic butterfly valves are suitable for open-close positioning and throttling operations since they are considered fast-acting valves.

Electric Actuated Butterfly Valve

Electric actuated butterfly valves may have an automatic, semi-automatic, or manual operation. Electric actuators are one of the most common types of actuators in butterfly valves because they are maintenance-free and reliable. These actuators allow electric actuated butterfly valves to be operated remotely.

The high-speed motor of electric actuated butterfly valves, which are usually reversible, are used for close and open functions. Electric actuators are connected through a gear train. They increase the torque by reducing the motor speed. Electric actuated butterfly valves are operated by the torque of the motor or by the position of the valve. To stop from fully opening or closing the valve automatically, a limit switch can be included.

Hydraulic

Hydraulic actuated butterfly valves can either be in an automatic or semi-automatic position. They are designed to regulate the flow of hydraulic fluid in a hydraulic circuit. Hydraulic actuators are often used to open a valve which requires a large force, such as the main steam valve. Also, they are utilized to redirect pressurized fluid or completely close a line.

Hydraulic actuated butterfly valves are closed using a spring force with no pressure coming from the fluid flow. The fluid changes the pressure inside the valve as it enters the chamber. When the valve opens, the piston moves upward to accommodate the force of the hydraulic fluid, which is greater than the spring force. The valve closes as hydraulic fluid enters one side of the piston, and the other side is bled or drained.

Hydraulic actuated valves are affordable, and they are used in various applications, such as food, pharmaceutical, and chemical industries.

Contact Our Experts

Send us a message if you have any questions or request a quote.We Offer:

- A reply from our experts within 24 hours

- The latest detailed product catalugue

- One-stop service for your project