SIO offers two-piece flanged ball valves that are specially built for zero-leakage sealing when control conditions require valve actuation exceeding 50,000 cycles. Our flanged ball valves have flanges with bolt holes that are used to lock them to matching flanges on the pipe. Gaskets are placed where the flanges connect to provide reliable sealing and prevent potential leaks. Flanges are an excellent means of connecting pipes, pumps, valves, and other components to produce a piping system. Having flanged connections make installation, removal, and cleaning easy.

Size:

1/2”-12”

Materials:

Body: Carbon Steel A216 WCB

Seats: PTFE

End Connections:

ANSI 150#

ANSI 300#

Flanged Ball Valves Selection Guide

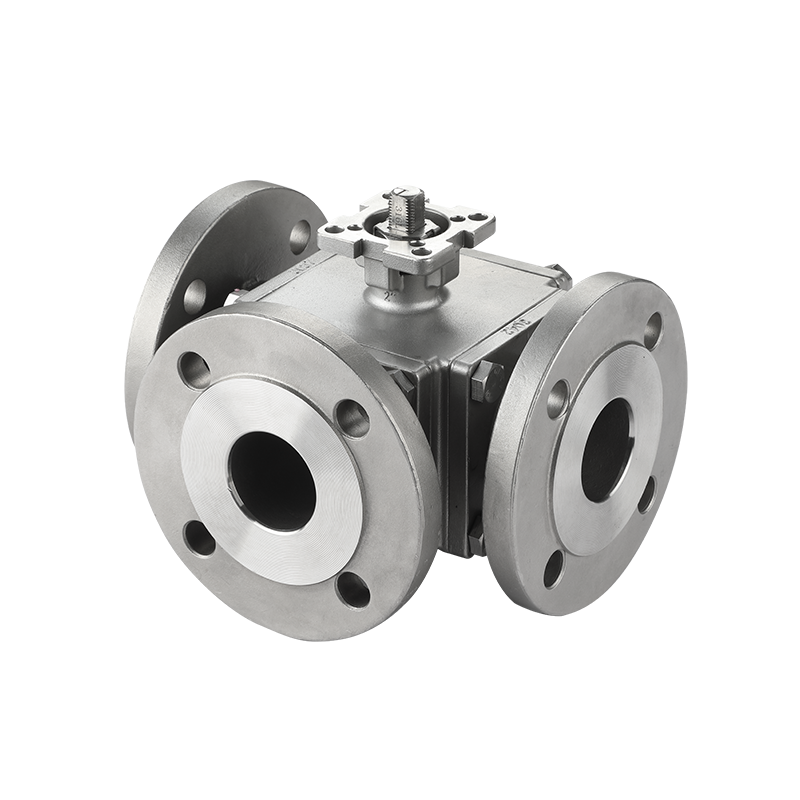

The main parts of a flange end ball valve include the cover, body, stem, ball, and seat. The cover is equipped with flanges mainly to install the valves into the pipelines. A ball valve flange can be manually operated by moving the lever in specific angles for open and closed positions. This ball valve type can also function through pneumatic or electric actuators. Flanged ball valve dimensions for the installation of actuators will vary, but are usually according to certain standards, like the ISO 5211.

As one of the top flanged ball valves manufacturers, we offer various customization options for our flanged end ball valves. Our two-piece flanged ball valves come in two models – ANSI Class 150 and DIN PN16-40. The maximum working pressure for our Class 150 model is 285 PSI, while for the DIN PN16-40 is 740 PSI.

The valve body is usually made from carbon steel or stainless steel, both are highly corrosion-resistant and temperature-tolerant materials that are great for crucial service conditions. The ball seats can be made from PTFE or RPTFE materials, which have high chemical resistance. They are available in sizes ranging from NPS ½” to NPS 12”.

Flanged Ball Valves Design Features and Options

Full Port for Unobstructed Flow

SIO flange end ball valve has full bore to ensure there are no obstructions in the flow. It is ideal in applications where low flow resistance and pressure drop are important. Having a full bore means the valves share a similar internal diameter with the pipes, which reduces pressure drop and cavitation. A full bore flanged ball valve is also widely used in media with mixed solids and liquids. This is to prevent build-ups that could affect the flow rate of the pipes.

Independent Stem Rotation

The rotational movement of the stem is independent with the adjustable Belleville washers and plate (the live loading system). The mechanism of stem rotation does not affect the sealing tightness of the disc plate. It also promotes quick quarter-turn rotation, which makes the flange end ball valve efficient and easy to operate.

High-performance Ball Seats

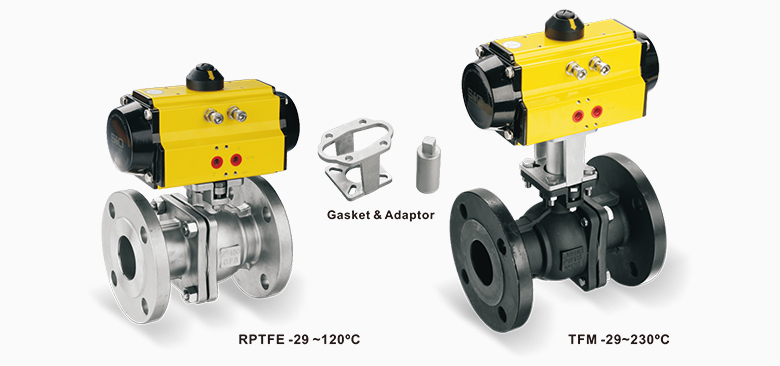

SIO offers two types of materials for the ball seats. PTFE, more commonly known as Teflon, is a type of plastic material highly resistant to chemicals. Its chemical compatibility is suitable for all types of media, including hazardous gases and toxic components, which makes it the most common material used for tight sealing.

RPTFE is a 15% glass-reinforced PTFE for enhanced strength and resistance to cold flow, abrasion wear, and permeation in molded seats. Reinforcement allows the flange end ball valves to operate in applications with high pressure and temperature.

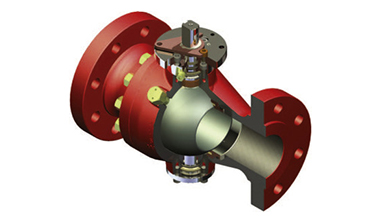

Blow-out Proof Stem

A blow-out proof stem contributes to the integrity of our flanged end ball valves. It means the stem is separated from the valve body to keep it from blowing out. In severe applications, the valve body will receive excessive pressure, which might cause the stem to dislocate. With a blow-out proof design, the stem is secured in place by the stem housing, which is attached to the valve body.

Antistatic Device

An antistatic device helps reduce accidental fire by providing a ground path to keep electrical conductivity between the valve body, ball, and stem. This ensures that the friction caused by valve operation does not cause static build-up. With the antistatic device, SIO ball valves will not produce sparks that could lead to fires and other accidents.

Fire-safe Design

An API 607 fire-safe system is a great addition to our flange end ball valve. The fire-safe design limits the acceptable leakage of ball valves when exposed to fire conditions. In case of an accidental fire, the metal seat retainers will connect with the ball to shut fluid flow, controlling internal leakage. Even when o-rings are damaged by the fire, our flanged ball valves will have a secondary graphite seal to prevent external leakage.

Live Loading Stem Sealing (Adjustable Plate and Belleville Washer)

Belleville washers are excellent for compression spring applications that need high loads in limited spaces. Their cylindrical structure allows them to hold high loads with small deflections compared to helical springs. They are widely used to address thermal expansion, vibration, and bolt creep issues.

The adjustable plate uniformly compresses the pair of Belleville washers to store energy for live loading, which extends the time required between maintenance. The live loading system works independently during high-cycle operations to maintain a reliable tight sealing.

Top Mounting Pad

We offer an ISO standard mounting pad so our flanged type ball valves can easily be actuated in several forms. The machined flat surface ensures proper alignment of the actuator to the stem top for minimum side loading during operation. Cast gasket and adaptor are also available for high-temperature applications to protect the actuators.

How Does a Flanged Ball Valve Work

A flanged ball valve is used to shut media flow in both directions. This SIO ball valve type is designed to be compact, simple, and generally the economical solution for flow control operations. It is an excellent alternative to lined-up plug valves and diaphragm valves.

A flanged ball valve operates similar to a typical ball valve. It is a type of quarter-turn valve used to release or obstruct media flow in pipelines. It has a spherical disc, more commonly known as a ball that has a hollow center which rotates to open or close media passage.

The difference is that the flange ball has a control spindle that controls the ball to open and closed positions. When the ball is pushed by system pressure against the side of the non-pressurized seal, the valve shuts the flow with no risks of leaking.

Applications for Flanged Ball Valves

Oil & Gas Industries

Our flanged ball valves are built to withstand demanding service conditions in the oil & gas industries. The ball seats ensure bi-directional and bubble-tight sealing while providing the lowest possible torque. Our TFM seat has an anti-expansion design for high-temperature applications.

Petrochemicals

SIO’s 2 flanged ball valve can endure chemicals and dangerous substances involved in petrochemical industries. It is equipped with a seat made from PTFE, which is the most chemical-resistant among plastic materials. It has excellent electrical and thermal insulation and useful in a wide temperature range between -40°C to 204°C.

Process Plants

The aggressive environments of processing plants require valves that are durable, reliable, and have a long service life. An SIO flanged ball valve is made from high-quality parts that promote tight sealing and low operational torque, which contributes to the ball valve’s long lifespan. Flanged ball valves also promote easy installation and removal, which are necessary for process plants.

Food and Beverage Industries

The food and beverage industries require that there is absolute zero leakage during operations. They also require valves that are durable and have excellent resistant abilities to pressure. SIO flanged type ball valves are made from durable materials that are corrosion-resistant and reliable parts that guarantee a bubble-tight shut-off.

Contact Our Experts

Send us a message if you have any questions or request a quote.We Offer:

- A reply from our experts within 24 hours

- The latest detailed product catalugue

- One-stop service for your project