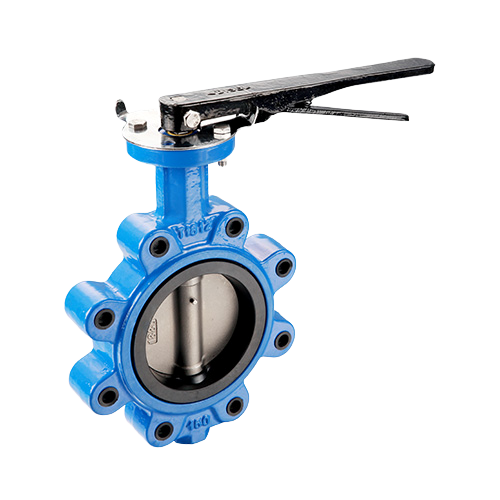

Resilient Seated Butterfly Valve

Features

- Economy & high performance

- One-piece body construction and self-centering disc.

- Seat facing acts as flange gasket.

- 3 shaft bushings support actuation.

- Shaft sealing against external leakage

- Meets MSS SP-67 and API-609 specs.

- Complete line of accessories

- Option: silicone free lined EPDM

Materials:

Body: Epoxy Coated Ductile Iron

Disc: 316 Stainless Steel (standard) NI Plated D.I. or Bronze available

Seats – BUNA-N or EPDM

End Connections:

Wafer: 2″ to 12″

Lugged: 2″ to 24″

Temperature Range:

BUNA-N: -4 to 194°F

EPDM: -22 to 230°F

Pressure Range:

225 PSIG (2″ to 12″)

160 PSIG (14″ to 24″)

Pressure Testing:

Body Hydro: 343 PSIG

Seat Hydro:243 PSIG

Dead End Service: (lug type only)

150 PSIG (2″ to 12″)

100 PSIG (14″ to 24″)

Available Actuators:

Electric

Pneumatic (spring return)

Pneumatic (double acting)

Manual Handle Lever

Manual Geared Hand Wheel

Contact Our Experts

Send us a message if you have any questions or request a quote.We Offer:

- A reply from our experts within 24 hours

- The latest detailed product catalugue

- One-stop service for your project