Plumbing systems in both homes and businesses use valves. Valves are mechanical devices that open, close, or partially restrict the flow of water in order to control, direct, and regulate it. They can be constructed from a variety of materials, including brass, bronze, and PVC.

Valves are used in residential and industrial structures, water supply systems, wastewater treatment facilities, and chemical factories to control water pressure, direct flow, and prevent backflow. There are many different types of valves, each with a distinctive design and a specific purpose. In today’s blog, we are going to talk about the types of valves in plumbing.

What is A Plumbing Valve?

With respect to sanitary or storm drainage facilities, a venting system, and public or private water supply systems, plumbing is the practice, use of materials, and erection of pipelines, fixtures, appliances, and appeals.

Plumbing valves are a type of equipment that regulates or directs the flow of fluid by partially obstructing, opening, or closing the valve. In an industrial plumbing system or process, a valve is a mechanical device that regulates the flow and pressure of a fluid. In essence, it regulates the flow and pressure.

Why Valve Plays An Important Role in The Plumbing System?

Valves are frequently employed in every business for a pipe system to control fluid flow, regulate fluid pressure, precisely calculate the ratio of any mixture, or take a sample of any product. In a plumbing system, valves generally limit, halt, and control the flow of fluid. In-depth, a plumbing system has valves fitted to:

- regulates and controls temperature gain or loss from a pipe system.

- according to the needs of the piping system, switches the flow from one direction to another.

- Limit the flow to maintain system balance and prevent overpressurization.

- In a system with one-way fluid flow, avoid reverse fluid flow.

- If a system failure occurs, stop the flow of any gases or liquids.

Despite their critical role in boosting productivity, regulating product quality, enhancing safety measures, and maintaining system functionality, valves are still infrequently mentioned during project design, building, or processing. One fundamental factor among several is that it has the lowest project-wide cost.

What Are the Different Types of Valves in Plumbing?

1. Ball Valve

Ball valves use a rotating ball in the valve’s center to regulate the flow of water. The water flow is controlled by the hollow core that runs through the center of this ball. Fluids are permitted to pass through the plumbing ball valves and exit out into the pipes when the hollow core of the ball is parallel to the water intake. Water cannot flow through the valve when the hole is turned so that it is perpendicular to the pipe.

A handle that is situated on top of the valve rotates the ball. A quarter turn of the handle is all that is required to stop the fluid flow. The hollow core of the ball is parallel to the valve and pipe while the handle is in that same position.

The most popular type of shut-off valve is a ball valve. Plumbing ball valves are commonly used in residential and industrial systems to turn the water on and off without a pressure drop because of their quickness, dependability, and durability. Any fluid cannot escape the valve because of the ball’s strong, watertight seal.

Plumbing ball valve is also widely used in chemical and natural gas applications because of their tight seal. Additionally, emergency situations when water needs to be easily and rapidly shut off are perfect situations for ball valves.

Of all shut-off valves, ball valves typically have the longest lifespan and are not prone to leakage or early failure. Ball valves ought to just be utilized to open and seal fluid passages, nonetheless. They are not designed to restrict flow because doing so could harm the valve’s seats or rotational ball.

Plumbing ball valves have several ports that they can use to direct or change the flow of fluids through. These multi-port valves may control the flow of water through up to four distinct channels. Ball valves are widely used and favored since the majority of shut-off valves are only intended to control valves in one way.

Advantages of Ball Valves:

- Simple and adaptable: Ball valves are low maintenance, have a small footprint, and provide dependable, tight sealing. Small plastic ball valves can be used to install a home water filtration system under the sink, while bigger brass ball valves can control the plumbing flow throughout the entire structure. They are the most popular valve option due to their wide variety of applications and ease of use.

- Ball valves are strong and effective, enduring high pressure and high flow rates without suffering any harm. They don’t need to be greased or maintained like other valves, and if used appropriately and with the right fluids, they shouldn’t need replacement parts either.

- Ball valves are more affordable than many other valves that perform related functions. They are more prevalent in household and industrial plumbing settings due to their low cost.

Disadvantages of Ball Valves:

- A ball valve is ineffective for throttling; it just isolates water flow. The seat of the ball valve will deteriorate and fail if it is used to throttle fluids or gases. You would be better off spending money on a valve made specifically for throttling, such as a globe valve or a needle valve if your intended use requires you to throttle fluids. Furthermore, a water hammer can result in closing the valve too quickly.

- Clogging: If a piece of silt or other particulate gets lodged in the center of the ball, it may lower pressure and damage the valve. This typically occurs when the valve is handling water with a lot of silt or when it is being used for fluids other than what it was designed for. It is essential to install a sediment filter to get rid of dirt and debris in order to prevent this issue.

2. Gate Valve

Another often used plumbing shut-off valve is a plumbing gate valve. A wedge-shaped metal gate that is part of gate valves can be lowered to stop the water flow and elevated to resume it. The gate completely retracts when it is fully pushed up into the valve, allowing water to flow through without any pressure loss. A wheel-shaped knob on the valve’s top is used to operate gate valves. The gate is gradually lowered into the valve by turning the knob. The gradual flow restriction that gate valves provide, which prevents water hammers, is one of their advantages.

A water hammer is a loud banging sound that occurs inside the pipe when water is forced to abruptly shift course or halt. Water hammering usually happens when a sudden shut-off valve is met by rushing water. The water pressure gradually drops as the gate opens and closes, preventing these pressure waves.

Plumbing gate valve must only be used to start or stop the flow of fluids, just like ball valves. They can harm the gate and over time decrease the valve’s effectiveness if used to throttle pressure. Gate valves work best in straight flow paths with few obstructions and detours, such as longer water supply lines.

Gate valves are typically seen in older plumbing systems. Plumbing gate valves tend to degrade over time and are more susceptible to corrosion and failure, therefore ball valves are typically seen as better options. Their handwheel knobs can also be problematic because it can be challenging to adjust the gate valve in constrained areas. If gate valves are only occasionally utilized, they will survive longer. A ball valve is a far better option for applications where the flow of fluids needs to be periodically turned on and off.

Advantages of Gate Valves:

- Low resistance: A gate valve’s straightforward construction lets water flow freely. The valve’s design does not in any way obstruct the passage of the fluids because the gate retracts completely into the valve’s body.

- Water pressure is permitted to change when the flow is either being restricted or released since gate valves open and close slowly, preventing water hammer. This safeguards your pipes and prevents the banging sound of water hammers.

Disadvantages of Gate Valves:

- Gate valves are vulnerable to wear and strain. The seal on the valve can deteriorate if the valve seat develops scratches. When a valve is used to throttle fluids, the gate will deteriorate and lose a lot of its efficiency.

- Manually raising and lowering the gate takes a lot of time. Gate valves require manual operation to open and close, in contrast to ball valves, which can be operated with a quick turn of the handle. This extra time can be expensive, particularly in emergency situations.

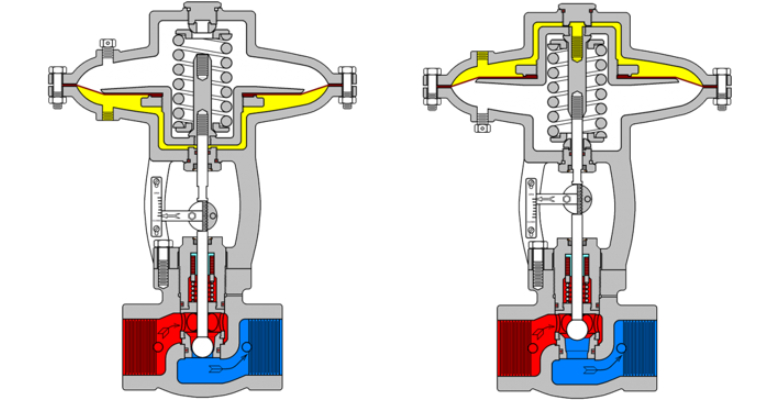

3. Globe Valve

Globe valves,as one types of valves in plumbing, are used to start, stop, and control fluid flow. Globe valves are intended to moderate and throttle water flow, in contrast to ball valves and gate valves. A fixed ring seat is housed in the body’s spherical valve, which gives the structure its nickname “globe.”

A rotating disc-shaped mechanism that spins upward when the handwheel knob is twisted is released from the ring seat, creating a Z-shaped tunnel that allows water to flow from one chamber into another. To enable a throttled flow and lower water pressure, the handle can be fully opened, sealed shut, or only half opened. They work similarly to a kitchen faucet or an outdoor hose bib in this capacity.

Like a ball valve or a gate valve, a globe valve can be used for isolation. Globe valves, on the other hand, exhibit a bigger pressure drop than conventional shut-off valves. They work best when handling fluids or steams at lower pressures because the curved Z-shaped interior of the valve is more flow restrictive than the designs of ball valves and gate valves. Globe valves can, however, be utilised to prevent water hammers because they open and close very slowly. Additionally, they don’t leak when working with low pressures.

Advantages of a Globe Valve:

- Dependable throttle: Globe valves, as opposed to ball valves and gate valves, are made to throttle the flow of fluids through them. Globe valves are frequently employed in situations where flow needs to be constantly regulated. Globe valves can be used for shut-off and isolation in addition to throttling.

Disadvantages of a Globe Valve:

- High-pressure drop: When compared to other valves, globe valves have a higher pressure drop. This is due to the fact that a globe valve forces fluids to shift their direction, increasing the flow’s resistance.

- Restrictions on flow: The globe valve’s special curvature design makes it effective for shut-off and throttling capacity, but as a result, the flow will still be controlled even when the valve is fully opened.

4. Butterfly Valve

Another plumbing shut-off valve frequently used to isolate and control water flow is the butterfly valve. A butterfly valve has a revolving disc at its center. This movable component is managed by a quarter-turn of a handle, just like ball valves. This disc flares open when the handle is turned, allowing liquid to flow into the pipe. The disc blocks all fluid movement when it is closed. The “rotary motion” family of valves includes plug valves, ball valves, and butterfly valves. This is because they use a rotating mechanism to control flow, which starts the flow’s closing.

Although a plumbing butterfly valve can be opened gradually, it is less efficient than globe valves for throttling fluids. It is not advised to use a butterfly valve to throttle fluid for long periods of time, even if some of them are made to lock into place with the disc only half open to preserve the throttled position. The disc part will deteriorate over time from exposure to rushing water, weakening the watertight barrier.

Although plumbing butterfly valve can be used in residential plumbing, butterfly valves are more frequently found in commercial plumbing. They take up little room, are portable, light, and simple to operate manually. They are therefore the best candidates for managing big amounts of gas and water. As with many facilities that process wastewater, sewage, and slurries, many municipal water treatment facilities employ butterfly valves on their supply lines.

There will always be a pressure drop when a butterfly valve is opened. When it is turned on, water is compelled to circulate around the rotating disc. Butterfly valves can only be utilized in certain situations since there is always an impediment in the pipeline when the valve is open. However, compared to other valves, plumbing butterfly valve are simpler to manually open and close against incoming water pressure since the disc pivots on an axis.

Advantages of a Butterfly Valve:

- Simple operation: Compared to most valves, especially those made for industrial usage, butterfly valves take up far less space. Their uncomplicated design is small, convenient to install, and smoothly functional. They are well-liked industrial options due to their simplicity and convenience.

- Low cost: Compared to other valves that perform identical duties, butterfly valves are typically far less expensive (like gate valves). Butterfly valves are among the most economically advantageous valves on the market since they are simpler to produce and use less material in their construction.

Disadvantages of a Butterfly Valve:

- Pressure drop: The range of applications for butterfly valves is constrained by their design. Because the central disc always remains in the valve’s flow stream, pressure drop cannot be avoided. A bypass valve may need to be placed to redirect some of the flow and maintain water pressure in order to reduce the pressure difference.

Where Can the Plumbing Valve be Used?

Conveying heating and cooling

In order to interrupt the flow of chilled water and condenser water during commissioning, repairs, and other situations, they function as isolation valves.

Gas and oil

Valves are an important component of every piping system, thus they have a significant impact on the oil and gas sector. Types of valves in plumbing can be used to regulate flow rates, isolate and safeguard machinery, and direct and guide the refinement of crude oil.

Wastewater

A wastewater valve is a component that regulates the pressure and flow of fluids, such as liquids and gases. Different types of wastewater valves allow different volumes of fluid to pass through them. The various wastewater valves come in simple to complicated designs. Wastewater valves are managed by flow meters and temperature gauges.

Water distribution

The most dependable and popular kind of valves used to control water flow are ball valves. To open the valve, a revolving sphere with a hole and an attached lever handle are used. The hole in the sphere is lined up with the pipe while it is in the open position, allowing water to pass through.

Factors to Consider When Selecting Valves in Plumbing System

1. Simplicity

Simply said, plumbing valve types should be simple to open when necessary, and vice versa. Even though this one task might appear basic, it is not in industrial plants. Valves can, unfortunately, become stuck owing to a variety of causes, such as corrosion, rust, and moisture buildup.

The valve should function exactly as intended for years, whether it is automated or manual. The performance of the system depends heavily on the estimated service life of the valve, just like it does for any other component of the pipe system. A malfunctioning valve results in expensive downtime and repairs.

2. Efficiency

On a modest, continuous scale, valves are essential to efficiency; also, they enable plants avoid downtime to a greater extent. A valve that is difficult to move or that is entirely stuck can lead to:

- Inadvertent chemical mixtures can be harmful.

- Continued flow in the direction of an upcoming leak.

- fluid to heat up beyond practical levels.

- A plant worker who attempted to manually close it was hurt.

The system’s continued productivity is another component of efficiency that valves affect. The system’s limiting factor is the point on the system with the lowest pressure or temperature rating. The integrity of the entire system may be jeopardized if a valve is incompatible with the medium of the line or has a lower temperature or pressure rating than the rest of the system.

3. Safety

The primary function of a valve is to guarantee safety. There may be a lot of problems if one sticks or leaks:

- If a reaction is fed, its chemistry may be changed or allowed to go on longer than necessary.

- A significant leak develops when a valve used to disconnect a pipe from a tank does not effectively seal it off.

- A check valve is the first line of defence in the event of an unintentional flow reversal.

- A valve must open if a failure happens farther downstream to stop further spills and reduce exposure to the chemical being transported.

- Unintentionally allowing two chemicals to combine can become dangerous in an industrial plant, and an inoperative valve can make this happen.

Contact Professional Plumbing Valve Manufacturer - SIO

In China, SIO valves is a well-known producer and supplier of industrial valves. SIO is committed to delivering safety, efficiency, and profitability to any business that requires automation. SIO has more than 10 years of experience in the design and manufacture of high-quality industrial plumbing valves.

We are committed to offering distributors, importers, and project managers all around the world the best industrial valves and machinery. We are able to satisfy even the most exacting demands and specifications thanks to our custom valve production. You can contact Sio Valve for further details.