Industrial diesel valves are used in pipelines to control, direct, and regulate the flow of fluids in a channel. It operates by opening and closing various passageways to control the media passing through it. The SIO valve is a significant part of the industrial piping system as it can handle a variety of fluids and materials, including powder and slurry.

It is essential for anyone working in the gasoline or fuel industry to learn everything about these different types of diesel valves as they are an indispensable component. These devices can handle a variety of materials and fluids. Its flow media often forms the basis of classifying them.

What are Diesel Valves?

A diesel fuel shut-off valve is designed to cut off the supply of fuel to an engine. Its primary function is to protect the system from damage when the running parameters exceed. These devices are available in two versions.

One diesel return valve operates by missing the fuel supply to stop the engine completely. And the other consists of an adjustable needle valve to allow sufficient flow to run the engine at an adjustable idle speed.

A diesel fuel shut-off valve is designed for applications where fuel shut down is needed as a part of automatic engine shutdown systems. While the hydro chemical engine fuel shut-off valves are suitable for use as failsafe valves in oil pressure-based hydromechanical systems, the air intake depression engine is perfect to operate in combination with diesel engine air intake valves.

A gasoline or diesel fuel valve can easily handle petroleum-derive flammable liquid as its body is manufactured using materials that offer excellent durability, corrosion resistance, and a wide range of pressure and working temperatures. Cast steel and stainless steel are typically used for constructing these devices.

How Do Diesel Fuel Shut Off Valve Work?

The primary function of a diesel fuel shut-off valve is to transport fuel from a machine’s gas tank to its engine. It is attached to a machine’s electrical system to monitor and detect abnormal temperatures or mechanical malfunctions. If anything goes wrong, the electrical current running through the engine interrupts, causing the China actuated gate valve to close and shut off the supply of diesel fuel to the machine.

In a solenoid fuel shut-off valve, the mechanical force is its coil which converts the electrical energy into magnetic energy that modulates the valve. It features an inlet pipe to transport the diesel fuel from the line to the valve, which consists of a rubber or plastic stopper held against the inlet pipe to seal it close.

The front part of the stopper contains a rubber o-ring to seal the inlet pipe and prevent the diesel fuel from entering the solenoid valve. Its cork remains in place by a metallic spring attached to the back end of the stopper, which connects to a metallic pin via a bar running perpendicular from the hook to the cork.

Since the pin is located near the coil, when the coil activates, the magnetic field draws the pin back, pulling the stopper back, thus breaking the seal with the inlet pipe. It lets the fuel in the diesel ball valve enter the solenoid valve.

Unlike a regular valve, diesel fuel shut-off coils are attached to sensors capable of receiving and interpreting electronic signals from the central electrical system of the machine. If the sensors detect a problem with the engine or operations of a device, the electrical signal running to the coil automatically shuts off.

When the coil deactivates, the force of the spring pushes the stopper back into place against the inlet pipe. This shuts off the flow of diesel fuel to the engine.

What Are the Different Valves for Diesel Fuel?

Here are some common types of diesel valves employed in industrial pipelines for various purposes:

Pressure Washer Fuel Shut Off Valve

These types of diesel fuel shut-off valves are typically installed inline between the fuel tank and the fuel pump on a hot water pressure washer. It allows for easy repair and replacement of the diesel supply line, fuel pump, and solenoid. It is also used during the winterization of a power washer.

It is available in a ¼-inch barb and a ¼-inch MPT to permit smooth retrofitting for usage on all brands of hot water power washers.

Pressure Control Diesel Fuel Valve

A pressure control valve is often used in industries to control the supply of fuel to the engine. It is located at the extremity, often at the pump outlet. A pump-external PCV involves lower manufacturing costs, but the proximity of the regulator to the injectors introduces additional disturbances in injector dynamics.

In a pump-integrated PCV solution, the fuel throttled by a ball type control valve joins the leakage coming from the pumping chambers and the power flowing in the pump’s lubrication and cooling circuits. This flow is combined to discharge from the pump to return to the fuel tank.

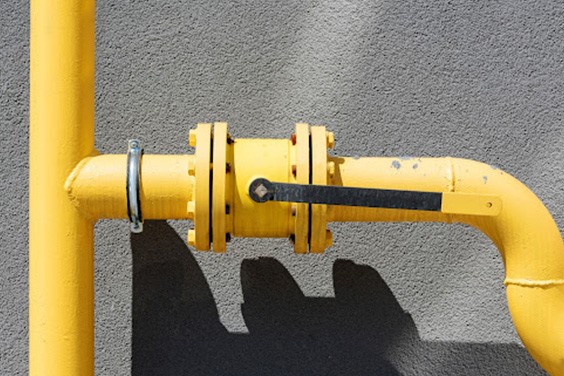

Ball Check Gasoline Valve

Ball checks or ball valves feature a built-in ball in their bodies. However, while a built-in ball valve rotates inside the valve body, a spring-loaded ball in check valves moves in linear motion. A ball valve is a quarter-turn device. When the ball turns inside the body, the flow of gasoline opens and closes accordingly.

Besides, butterfly, gate, plug, diaphragm, check, relief, and needle valves are also employed in industrial operations.

Diesel Fuel Pressure Relief Valve

A diesel one way valve is designed to accommodate the needs of today’s diesel engines as it is vital to maintain the integrity of the system while caring for the life of system components.

A pressure relief valve provides this peace of mind to the users. It also protects filter housings, hoses, fittings, seals, and pumps by eliminating any pressure spikes and irregularities. Often made using high-quality materials, these devices are durable and reliable. One can install them even under the harshest of operating conditions, and they will work fine.

Gasoline or Diesel Fuel Check Valves

This wholesale actuated globe valve is used in a variety of applications in oil refineries and power plants to prevent the backflow of media in piping systems. Its operation helps prevent damage to downstream apparatus, including compressors and pumps

Fuel Quantity Control Valve (FQCV)

Also referred to as an inlet metering valve or flow regulator, a quantity control valve is designed to control the quantity of diesel flowing from the low-pressure or lift pump to the pistons of the high-pressure pump. More significant amounts of fuel allowed to the pistons of the high-pressure pump result in a higher pressure generated. It thus causes higher pressure in the common rail.

If smaller amounts of fuel are allowed to the pistons of the high-pressure pump, it may generate lower pressure and thus create more downward pressure in the common rail. FQC valves control the quantity of fuel supplied to the high-pressure pump pistons to cause lower fuel temperature, eliminating the need for a cooler and reducing the load on the high-pressure pump. If there is any excess fuel, it returns to the tank.

Factors to Consider When Selecting Diesel Fuel Valve:

Here are a few vital factors to take into consideration when choosing the ideal diesel fuel valve.

Type of Media

The choice of diesel fuel valve depends significantly on the type of media flowing through it. It is so because the characteristics of liquid or gas type greatly determine the valve material to be used. It is vital to buy valves that can easily handle hash and corrosive materials flowing through them.

Usage Conditions

The application conditions greatly influence the choice of valves. The device should be sized appropriately because if it is improperly sized, it can cause operational issues within it or elsewhere in the system. Besides, it is equally crucial to determine the temperature, pressure, and flow rate under which it will work.

Pressure Differential

Diesel fuel shut-off valves are different from pumps in the sense that there is no mechanical device to force the diesel fuel through them. As a result, when purchasing a diesel fuel shut-off valve for industrial operations, it is imperative for them to have a pressure differential between the inlet and outlet pipe.

It is vital to consider that the inlet pipe has a higher pressure than the outlet pipe to force the fuel through the valve. If the pressure is equalized, the diesel check valve might prevent the diesel fuel from flowing through the device, regardless of the state of the stopper.

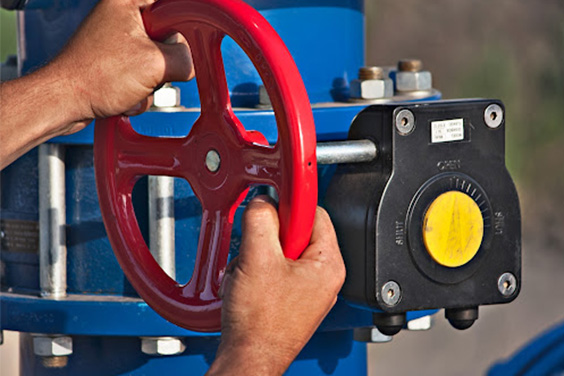

Actuation Technique

How to operate the valve is another critical consideration. That’s why it is essential to identify the actuation technique. Suppose it is to be operated manually or automatically. If the latter option is chosen, determine if the unit will be used with an electric, pneumatic, or hydraulic actuator.

Maintenance Needs

Lastly, maintenance requirements are an essential consideration when choosing a diesel valve. If maintenance needs to be done regularly, ball valves are a great option as they prevent clogging and are easy to service.

Performance Needs

Before buying a valve, it is vital to determine its pressure and temperature requirements. Find out the temperature and pressure ranges where it will be installed. For diesel and gasoline operations, valves made of metal are the best as they can withstand extreme temperatures very quickly and are way stronger than plastic valves.

Contact Industrial Valve Manufacturer to Get Diesel Valves:

Diesel fuel valves are an essential component of industrial pipelines. As widely as they are used in every process and system, choosing the right one can sometimes be a time consuming and confusing procedure. Selecting the correct valve means matching its size to the expected flow through the industrial piping system.

We hope the above tips help everyone know where to begin when they want to choose an ideal valve fastly and easily for certain operations. If anyone is looking to purchase high-quality diesel fuel valves along with personalized customer service and the finest team to help everyone make the best choice contact us.