Table of Contents

High-pressure applications are a part of every kind of industry. Hydraulic, oil and gas, cosmetic, pharmaceutical, and other industries require specialized valves to regulate the flow of the high-pressure medium. High-pressure ball valves help solve this problem. These ball valves are designed to handle liquid, gas, corrosive and slurry material flowing at a higher pressure than normal.

High-pressure ball valves are suitable for applications where the medium is flowing at a pressure greater than 3000 psi. High-pressure 3-way ball valves can even handle mediums flowing at a pressure greater than 15000 psi. Whether it is a three-way ball valve, ball valve flange type, or metal seat ball valve, they are designed to withstand the wear and tear associated with high-pressure applications and are suitable for critical operations in any industrial unit.

How are High-Pressure Ball Valves Constructed?

High-pressure ball valves are constructed in the same way as other ball valves. However, some of their parts like the stem, seats, and ball are reinforced to handle additional force and pressure from the onstream. They can be customized according to the application, the nature of the medium, and the pressure rating. Here is a diagram of a high-pressure ball valve.

Body

The body of high-pressure ball valves is made of materials like carbon steel, stainless steel, low-temperature carbon steel, duplex, super duplex, Inconel, and more depending on the application. Anti-static materials are used to make the body of the valve ensuring proper function and durability.

Stem

The stem of high-pressure ball valves is extended and can handle cryogenic and high-temperature applications. The stem connects the actuator to the ball so it has to handle most of the pressure from the onstream. High-pressure ball valves usually feature anti-blow out stems so they can easily handle all the added pressure.

Seats

The seats in a high-pressure ball valve are reinforced with special seat rings that can handle the high pressure from the onstream. In high-pressure floating ball valves, the elastomeric seat rings have O-ring seals so they are not damaged by the constant pressure on the valve.

Ball

The ball in a high-pressure valve is made of carbon steel or stainless steel depending upon the type of medium and application. The surface of the ball is perforated to help distribute the pressure evenly. High-pressure ball valves may have full-bore or reduced-bore balls. Full bore balls are used in operations where the unrestricted flow of medium is required. Reduced bore balls are more suited for operations where the pressure of the medium needs to be minimized by restricting its flow.

Actuator

High-pressure ball valves can be turned on and off using both manual and electric actuators. Hand levers, pneumatic actuators, and motor-operated actuators are more commonly used to operate the valve. Manual actuators are preferred in high-pressure applications or where trunnion mounted ball valves are being used. Electric actuators are more suited to extreme high-pressure applications or with floating ball valves.

How does a High-Pressure Ball Valve Work?

High-pressure ball valves work in the same as most ball valves. They are quarter-turn valves that help regulate the flow of liquids, gasses, slurries, and corrosive fluids. High-pressure ball valves are sometimes accompanied by a swing check located within the ball to give the valve a check valve feature. Here is a diagram of a typical high-pressure ball valve with swing-check.

Source: http://www.valvehydraulic.info

High-pressure ball valves are typically used in the water industry which is why they are also known as hydraulic ball valves. High-pressure hydraulic ball valves help you manage the flow of fluid flowing through a pipeline at pressures greater than 3000 psi. For example, to control the flow of water flowing at a pressure of 7500 psi in a hydroelectric power plant, you would install a specialized valve like the SIO air operated ball valve. The valve will be installed in the pipeline through welded or threaded connections.

Source: https://www.sciencedirect.com

To open the valve, you will move the actuator to 90 degrees. As the actuator is rotated, it will move the stem, which in turn will rotate the ball. The ball will rotate just enough so that the hollow side of the ball is in line with the pipeline. The water will flow, unrestricted through the valve to the other end of the pipeline. To stop the flow, you will rotate the actuator again, making sure to complete the 90-degree angle. This will rotate the ball so that the hollow side or bore is now perpendicular to the pipeline. This will stop the flow as the pressure from the onstream will cause the ball and seats to form a firm seal.

High-Pressure Ball Valve Applications

High-pressure ball valve provides tighter shut-offs and are easy to use. They are also suitable for critical operations and can handle corrosive materials without getting damaged. High-pressure carbon steel ball valves are used in many different industries to manage various applications.

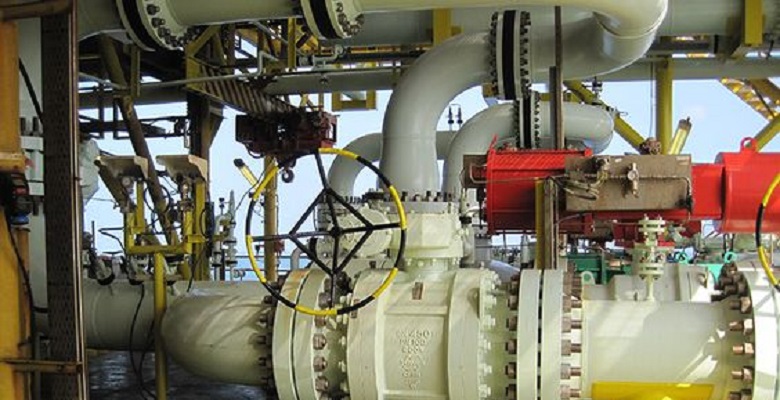

In the oil and gas industry, high-pressure ball valves are used to manage high-pressure operations in extreme temperatures. As they can handle both cryogenic and high-temperature operations, ball valves can manage many different operations in an oil and gas factory unit.

High-pressure ball valves made of stainless steel or carbon steel are corrosion and abrasion-resistant, making them perfect for managing operations with sensitive mediums. For example, SIO API-6D High-Pressure Ball Valve is used frequently in the pharmaceutical, food, and cosmetic industry. All these industries require leak-proof, durable, high-pressure ball valves to regulate the flow of sensitive and corrosive mediums.

2-way and 3-way high-pressure ball valves are commonly used in the hydraulic, cosmetic, pharmaceutical, and food industry to manage high-pressure operations. These ball valves can handle the flow of medium in different directions while ensuring tight shut-offs so that there is no mixing or leaking of the different fluids or gasses.

High-Pressure Floating vs. Trunnion Mounted Ball Valve

Floating and trunnion mounted ball valves are the two most popular types of ball valves found in the market. Both of them provide tight shut-offs but they have different construction and mechanism.

Construction

Floating ball valves feature a hollow ball that is connected to the stem on one end but is free to float inside the trim otherwise. The seats of a floating ball valve are made of an elastomeric material. Trunnion mounted ball valve features a perforated, hollow ball that is connected to the stem on one end and a shaft called the trunnion on the other. The ball can only rotate on its axis but is held stationary otherwise. The seats of the trunnion mounted ball valve are spring-loaded.

Function

A floating ball valve provides a tight shut-off when the onstream pressure pushes the ball and the upstream seat against the downstream seat. In trunnion mounted ball valve the pressure from the onstream pushes against the seats activating their springs. This causes the seats to move towards the ball, making a tight seal.

Application

High pressure floating ball valves are more commonly used in operations where there are no pressure changes in the medium. The onstream pressure pushes the ball to the downstream seat making a seal. If there are drops in pressure, the seal might not remain as tight. If the pressure suddenly increases, the downstream seat might not be able to handle the added pressure. High-pressure floating valves use O-rings and extra packing to ensure durability and ease of operation.

High-pressure trunnion mounted ball valves are more suitable for very high-pressure operations and applications where pressure fluctuations are expected. Unlike floating ball valves, the seats and ball in a trunnion mounted ball valve don’t take on all the pressure from the onstream. The pressure is divided between the seats, ball, stem, and trunnion of the valve. Since pressure is evenly distributed, any highs or drops do not affect the seal formed by the ball and the seats. High-pressure trunnion mounted ball valves can be easily used for large scale projects as well. However, these valves are larger in size and more expensive than floating ball valves.

Conclusion

Ball valves are suited for high-pressure operations because they provide tight seals and have a quick operation. These quarter-turn valves can be used to handle high-pressure operations in any kind of unit and in extreme temperatures. High pressure steam valves are easy to operate by using manual, electric, or pneumatic actuators. Their solid build and high-pressure compatible mechanism makes them a great choice for both large and small projects. As one of the best high pressure ball valves manufacturers, our ball valves are API 6D, API 598, BS EN 12266 -1 and 2 pressure rating certified. We can also customize valves to handle specialized applications. Get in touch with us for more information.