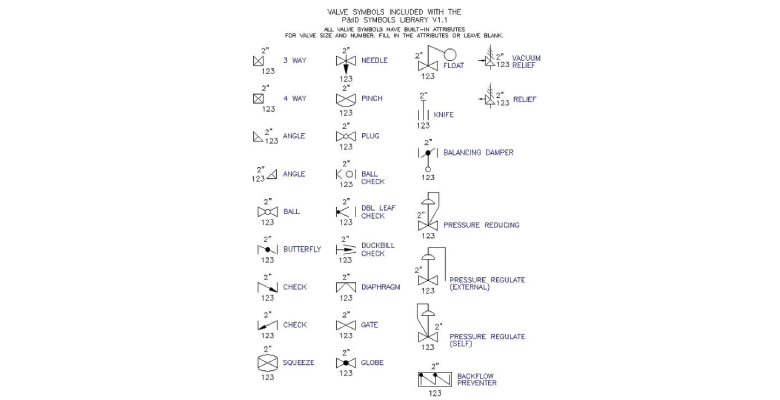

A valve can be defined as a style of fitting that regulates, controls, and directs the flow of fluids via a pipe. Valves are often employed in water distribution systems to guide the flow, shut off water access, prevent backflow, and alter water pressure.

This article elucidates the various kinds of valves and a complete buying guide to consider before purchasing valves.

What Is A Water Supply Valve?

Water supply valves control the flow and temperature of water through pipelines and plumbing fittings. These valves also maintain a steady flow and volume when correctly placed and operated properly. They are frequently employed in a wide variety of economic and industrial applications.

Wastewater treatment plants, pharmaceutical factories, chemical plants, and car production all depend upon water supply valves for fluid control and direction. Though valves are a kind of fitting, they’re often addressed as a separate, distinct category as each valve acts independently.

Plastic, lead-free brass, cast iron, stainless steel, and galvanized tubing are among the materials used to make valves. There are different kinds of valves used in the water distribution systems and each serves its own function.

Why Valve Plays An Important Role In The Water Supply And Distribution System?

Valves are essential components of the water distribution system. The distribution system includes a lot of components including storage tanks, pipes, valves, and hydrants. There are various types of valves in water distribution systems and some of the ways why valves play an important role in the water supply and distribution system are as follows:

Wastewater Treatment Plants

The wastewater treatment process is usually divided into three stages: primary, secondary, and tertiary. Ball valves or plug valves are employed during most stages of the wastewater process. This is so because it’s vital to own valves that will manage slurries since the wastewater at this point still contains sediment, particles, and sludge.

Power-actuated control valves, wafer butterfly valves, and check valves are employed during the second stage when the leftover organic debris is removed utilizing aeration systems that these kinds of valves are effective for. Check valves, cutoff valves, butterfly valves, and ball valves are utilized at the tertiary stage as there’s no silt within the effluent.

Desalination Of Seawater

Desalination is the process of converting salty water into potable water for human and industrial use. Because the liquids employed in the desalination process are corrosive, it’s critical to utilize long-lasting valves constructed of corrosion-resistant materials.

Butterfly valves are often employed within the seawater inflow, and filtration, and provide phases of the method, whereas diaphragm valves are utilized within the water pre-treatment and post-treatment stages.

Filtration Of Particles

Particle filtration is employed to separate water from solid materials like mud, sand, plant residues, and other pollutants. This process is also used to filter water from various water bodies like lakes, rivers, and wells. Butterfly valves are typically utilized during this technique for purification, especially for water with an occasional level of pollution.

Circuit For Industrial Water Cooling

Isolation or control valves are commonly employed in industrial water cooling circuits. High-performance butterfly valves are frequently utilized in systems with large-diameter pipes.

Purification Of Sewage

Basins are utilized in the method of domestic sewage purification. Underwater butterfly valves are often put at the sewage inflow and exit.

What Are The Different Types Of Valves In Water Distribution Systems?

Ball Valves

Ball valves are a typical form of the shut-off valve. They control water flow in pipes by a rotating ball located within the center of the valve. This ball encompasses a hole within the center that controls the flow of water. When the outlet within the ball is parallel to the water intake, water can rush through the valve and into the pipes.

The channel is stopped and water cannot flow through the valve when the outlet is rotated 90° to the pipe employing a handle. A quarter-turn of the handle is enough to prevent the flow of water.

Ball valves are widely used In water distribution systems thanks to their dependability, speed, and longevity. These valves are commonly utilized in residential and industrial settings to begin and stop water flow without causing a pressure decrease. The ball creates a firm, watertight seal within the valve, preventing leakage. Ball valves also are useful in emergency situations where water flow must be instantly stopped. These valves, however, can only open and stop water passageways. They cannot regulate the flow since doing so risks ruining the seats or the ball.

Ball valves of assorted types may change or divert water flow through several ports. Water could also be diverted through up to four distinct tracks using multi-port ball valves. Most shut-off valves are only designed to manage valves in a technique.

Advantages of ball valves

- High productivity

- Ball valves are called high recovery valves because of the scale of the orifice within the ball and their minimal pressure drop and high flow capacity.

- Convenient application

- Low upkeep

- Cost-effective

- Robust

- Prone to clogging

- Long-term throttling could be a challenge

Gate Valves

Gate valves are widely employed in water distribution systems. A wedge-shaped metal gate is placed, which might be lowered to prevent water flow and lifted to revive flow. When the gate is fully lifted, it entirely retracts, enabling water to flow through with no pressure decrease. On top of the valve, a wheel-shaped lever operates the gate valves.

One can regulate the movement of the gate within the valve by turning the lever. These valves provide progressive flow limitation, preventing blast. Sometimes a loud noise is caused by an abrupt change in direction or halts, leading to a hammering sound within the pipe.

Gate valves, like ball valves, simply start or stop the flow of water because utilizing them for throttling will reduce their efficiency. Gate valves are ideal for straight-line flow with little constraints and diversions, like in large facility lines.

In general, gate valves are seen in older plumbing systems since ball valves are more reliable nowadays. Furthermore, they will last longer if used just occasionally. A valve is good for water systems where the flow of water must be switched on and off more often.

Advantages of gate valves

- Fluid resistance

- Energy-efficiency

- Dual flow direction

- Minimal erosion

- Minimum pressure loss

Globe Valves

Globe valves are commonly accustomed to controlling water flow in pipes. Globe valves, unlike ball valves and logic gate valves, are designed to begin, halt, and throttle the flow of water.

When the knob on the outside of the valve is turned, a disc-shaped mechanism opens a Z-shaped passage, allowing water to ensure from one area into another. The knob could also be turned entirely open and closed partially to limit the flow.

Globe valves have a greater pressure drop than other kinds of shut-off valves. The curved Z-shaped tube inside the valve restricts flow quite like a ball logic gate valve. As a result, they’re suitable for controlling water flow at low pressures. Globe valves, on the opposite hand, avoid eruption since they open and shut gently.

Advantages of globe valves

- Excellent shut-off capabilities.

- Throttling capacity starts from moderate to excellent.

- Has a shorter stroke (compared to a gate valve)

- Available in tee, wye, and angle patterns, each with its own set of characteristics.

- Seats are simple to machine or resurface.

- When the disc isn’t attached to the stem, the valve is utilized as a stop-check valve.

Butterfly Valves

This valve is another form of shut-off valve that helps to control water flow. A valve contains a revolving disc within the center. Like ball valves, this moving disc is controlled by a quarter-turn of a handle. This disc bursts open because the handle is twisted, enabling water to enter through the valve. When the disc is closed, it prevents water from moving.

Butterfly valves are a part of the rotary motion valve family. This is often because of the fact that they manage water discharge by running a mechanism that causes the flow to shut. Although less functional than globe valves, a butterfly valve is also progressively opened to throttle water.

Some valve designs lock the disc half receptive and keep the throttled position. However, it’s not recommended to utilize a valve to throttle flow for extended periods of your time. Continuous exposure to flowing water will corrode the disc and compromise the watertight seal.

Advantages of butterfly valves

- Butterfly valves are lightweight, small, and easy to use.

- They’re suitable valves for controlling enormous amounts of water and gas.

- This valve guarantees a high-pressure drop.

- The disc is lighter than a ball, and therefore the valve requires less structural support than a valve of comparable diameter.

- Butterfly valves are extremely accurate, making them useful in industrial applications. they’re quite reliable and need little maintenance.

Needle Valves

Unlike the other valve, needle valves provide extremely fine flow control. They regulate the flow of water by lifting and lowering a threaded, conical spindle. The pointed tip of the spindle fits nicely on the valve seat at the valve’s bottom. A needle valve is activated by a revolving stem. because the stem is turned. The spindle gradually moves out of its valve seat, allowing water to flow via the limited route within the valve. Water flow is isolated, regulated, and throttled using needle valves.

Each twist of the stem causes a regulated increase in flow. This provides the operator with complete control over the flow of water. Needle valves are most ordinarily employed in systems where flow must be controlled carefully to safeguard equipment. They’re also appropriate for tasks requiring a gradual shut-off of the flow or a really low rate. Despite the small size of the water entrance and internal spindle, needle valves can withstand extremely high pressures

Advantages of needle valves

- The flow control is precise at low rates.

- Needle valves are more compact.

- Such valves function as bleed valves in quandary heating systems.

- These valves are simple to shut.

Plug Valves

A plug valve could be a cylindrical valve that is an isolation or redirection device. Within the plug, valve could be a cone-shaped “plug” with a hole within the middle. When the lever is moved 1 / 4 turn, the stopper spins, allowing water to flow through. When the outlet is closed, it spins flush with the valve walls, preventing flow.

Plug valves with several ports can even be used to divert flow over various channels. The ports on plug valves are available in different shapes such as rectangular, diamond, or circular. Round and rectangular apertures give unhindered water flow, whereas diamond ports obstruct flow.

These valves, however, can’t be utilized to manage the flow. the look of plug valves is fairly basic. Furthermore, its operation is comparable to it of ball valves

Advantages of plug valves

- Plug valves feature a basic design with few components.

- Plug valves have a coffee flow resistance.

- It provides dependable leak-proofing.

Air Logic Valves

Air Logic Valves are mechanical or electro-mechanical devices that are used to control the flow of air in pneumatic systems. The actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage are all important criteria to be considered while using the aerosol valves for the water distribution system.

Advantages of aerosol valves

- Air logic valves have a lot of uses. They are employed in pneumatic systems as e-stops, pilot valves, one-shot valves, and other functions.

- When the valve is open, there’s always resistance within the pipeline, which limits where butterfly valves are also employed.

Balancing Valves

Balancing Valves manage fluid flow by splitting it equally into several flow branches. The number of ports, port connections, valve size, and construction materials are all important parameters when managing the water distribution system. Balancing valves are typically employed in HVAC and fluid power systems.

Advantages of balancing valves

- Such valves are employed in commercial heating/cooling systems

- It helps to vary water temperatures under various loading situations.

- Balancing valves also provide a counterbalancing force for double-acting cylinders.

Check Valves

Check Valves allow liquids to flow in one direction. Lift-type check valves are just like globe valves as they employ a ball or piston, which is usually supported by a spring. This helps to open under a particular pressure but closes when the pressure lowers, preventing backflow. These valves are frequently employed in high-pressure applications.

The stop check valve, which also is a shut-off valve, may be a variation. Swing check valves use hinged gates, disc wafers, or wafers that are frequently spring-actuated to shut against ports when the pressure drops. These devices have the potential to be useful in low-pressure situations.

The theme is varied significantly by a tilting disc check valve, which hinges the gate slightly inward to reduce the pressure required for opening. Rubber check valves also are available, with designs like the flap and duckbill. They are tiny, a product of plastic, and have numerous particular characteristics, like metal seats.

Advantages of check valves

- Check valves are utilized in gas lines, airlines, and pumps—anywhere a fluid must flow in a particular direction.

- Small size and lightweight, which make them easy to handle

- They can also be used in remote control systems or other applications where there are limitations on the amount of machinery you can use.

Factors To Consider When Selecting A Water Distribution Valves

The correct valves should be employed in water distribution systems to ensure optimal overall performance. Consequently, certain things need to be considered when selecting a water distribution valves

Context In Use

The kind of valve required is decided by the situations under which the valve will be utilized. For instance, gate valves are appropriate for situations involving high pressures and temperatures. Similarly, butterfly valves aren’t intended for slurry applications, rather are intended to work in settings where slurries aren’t present, like within the last stages of wastewater treatment or in seawater inlets. Check valves are used to promote uninterrupted liquid flow by preventing backflow. It’s critical to know the circumstances that every variety of valve can withstand and also the usual applications during which it’s employed.

Pressure Loss

Low pressure is critical for any water distribution system. When water is pumped at high pressure, any loss in that pressure results in wasted energy. Hence any pressure loss across the system increases energy consumption.

Size

Choosing the proper valve for a given application begins with getting the sizing right. Thus, flow, pressure, and temperature all need to be taken into account. Valve selection criteria may also include tests, model standards to a certain market, as well as the actuation type and force needed to operate the valve properly.

Contact Professional Industrial Valve Manufacturer - SIO

SIO Valve has great expertise in producing industrial valves for water distribution. These valves play a major role in the smooth functioning of different machines. Moreover, the wide range of valves caters efficiently to the requirements and quality standards. Different industries utilize these valves most commonly for a smooth manufacturing process. With SIO the business would only expect professional and expert assistance in valves. Contact SIO for more details.