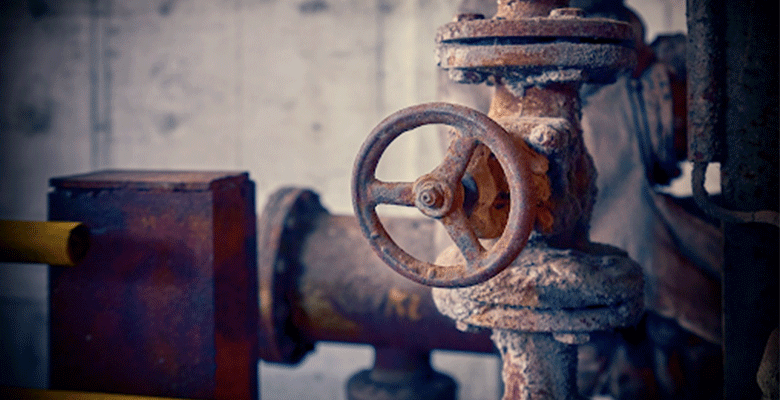

Valves are tiny devices used to isolate, regulate and restrict the flow of certain liquids or gases through the piping system. It performs this function by partially opening or closing, allowing only the necessary liquid to pass through. These valves are formed of different materials such as brass, bronze, PVC, and others. Different kinds of water valves have different features and applications. While some might be a perfect choice for chemical plants, others might be suitable for wastewater management.

What Is A Water Valve?

A water valve is a kind of fitting that enables fluid flow via a pipe to be regulated, controlled, and directed. Different types of water valves are frequently employed in systems to control water pressure, stop backflow, direct flow, and shut off access to water.

The use of valves, may isolate plumbing systems for repairs or turn off a water supply when a leak appears. In the majority of commercial and industrial applications, these are generally employed. Valves are essential for the direction and control of fluids and gases in chemical plants, pharmaceutical factories, wastewater treatment facilities, and automobile factories.

What Are The Different Kinds Of Water Valves?

There are different kinds of water valves available to meet the varying demands of the industries. Each type of valve has its own specialties, advantages, and principle of working that needs to be considered before selecting one for use.

1. Water Diaphragm Valve

A flexible diaphragm is used in a water diaphragm valve to block, regulate, or isolate fluid flow. The diaphragm serves as the flow control component, flexing up or down to alter the rate of fluid flow, as required. As the diaphragm is forced against the solid dam inside the valve body, the sealing action of the valve is produced. A water diaphragm valve is categorized as a linear motion valve because it needs the flow control element to move linearly.

Advantages

- Throttling applications benefit from the usage of diaphragm valves.

- Diaphragm valves are hygienic and exceptionally clean because the regions or pockets that capture sediments or biofilms are lesser.

- These valves perform remarkably well for handling highly viscous, sticky, and particle-containing fluids.

- With diaphragm valves, there is little chance of stem leaking into the environment.

- The diaphragm valve’s working mechanism is separate from the medium that is flowing through it. Contamination is, therefore, less likely to occur. The fluid won’t obstruct the mechanism’s operation. Moreover, the pipeline may be serviced and maintained without stopping it.

Why They Could Be Used In Water Application

Diaphragm valves perform well with liquids, gases, and semi-solid media such as brackish water, slurries, and colloids. These valves are perfect for handling liquids that contain solid particles. They are built considerably more simply than conventional valves.

Diaphragm valves are less susceptible to the accumulation of sediments and biofilms due to the low contact created by their interior components.

2. Ball Valve

Ball valves are commonly used as shut-off valves in water systems. Ball valves are commonly used in residential and industrial applications to turn the water on and off without a pressure drop because of their agility, dependability, and durability. Any fluid cannot escape the valve because of the ball’s strong, watertight seal.

Water ball valves are also widely used in chemical and natural gas applications because of their tight seal. Additionally, ball valves are fantastic for emergency situations where water needs to be easily and quickly turned off.

Advantages

- A Water ball valve is low maintenance, has a small footprint, and provides dependable, tight sealing. Small plastic ball valves can be used to install a home water filtration system under the sink, while bigger brass ball valves can control the plumbing flow throughout the entire structure.

- They are the most popular valve option due to their wide variety of applications and ease of use.

- Ball valves are strong and effective, enduring high pressure and high flow rates without suffering any harm. They don’t need to be greased or maintained like other valves, and if used appropriately and with the right fluids, they shouldn’t need frequent replacement of the parts either.

Why Ball Valve Could Be Used In Water Application

Most ball valves for water systems have several ports that they can use to direct or change the flow of fluids through. These multi-port valves may control the flow of water up to four distinct channels. They are widely used and can be categorized under the plumbing water valve types.

They are mainly used in residential plumbing systems since the majority of these valves are user-friendly and have efficient controlling mechanisms.

3. Gate Valve

Gate valves for water have a wedge-shaped metal gate that may be lowered to stop the water flow and lifted to resume flow. The gate completely retracts when it is fully pushed up into the valve, allowing water to flow through without any pressure loss. A wheel-shaped knob on the valve’s top is used to operate gate valves. The gate is gradually lowered into the valve by turning the knob.

Advantages

- Low resistance: A gate valve’s uncomplicated construction lets water flow freely. The valve’s design does not in any way obstruct the passage of the fluids because the gate retracts completely into the valve’s body.

- Water pressure is permitted to change when the flow is either being restricted or released since gate valves open and close slowly, preventing water hammering. This safeguards your pipes and prevents the banging sound of water hammers.

Why Gate Valve Could Be Used For Water Application

With gate valves the water pressure gradually drops as the gate opens and closes, preventing pressure waves. The gate valve for water works best in straight flow paths with few obstructions and detours, such as longer water supply lines.

4. Butterfly Valve

A butterfly valve is a type of shut-off valve that is widely used to isolate and regulate water flow. To throttle fluids, a butterfly valve can be opened gradually. To maintain the throttled state, some butterfly valves are made to lock into place with the disc just half open. The “rotary motion” family of valves includes butterfly valves. This is due to the fact that among different kinds of water valves only they manage flow by deploying a revolving mechanism that begins flow closure.

Advantages

- Butterfly valves are much smaller than the majority of valves, especially industrial-grade valves. Their uncomplicated design is small, convenient to install, and smoothly functional. They are well-liked industrial options due to their simplicity and convenience.

- Compared to other valves that perform similar duties, butterfly valves are typically far less expensive. Butterfly valves are among the most economically advantageous valves on the market since they are simpler to produce and use less material in their construction.

Why They Could Be Used In Water Application

Although they can be used in residential plumbing, butterfly valves are more commonly found in commercial plumbing. They take up little room, are portable, light, and simple to operate manually. They are therefore the best candidates for managing vast quantities of gas and water.

5. Pressure Relief Valves

In the plumbing system, pressure relief valves are used to reduce water pressure to the desired limit and safeguard equipment or pipe systems from bursting. Depending on the pressure of the water supply, the spring and diaphragm make up the mechanism, which is adjusted to a certain limit.

Advantages

- The pressure relief valves are reliable and dependable if operated and scaled in a correct manner.

- It is rather versatile, such that it can be employed in a variety of applications including firefighting, high-rise buildings, water towers, drinking water applications, and water tanks.

Why They Could Be Used In Water Application

When a condition arises that causes the pressure in a system or vessel to rise to an unsafe level, the pressure Relief Valve may be the only device left to avert a catastrophic failure. The pressure Relief Valve’s design is as simple as it can be because device complexity directly affects reliability.

6. Check Valves

Pipelines typically have check valves fitted to stop backflow. In essence, a check valve is a one-way valve that permits free flow in one direction but closes to safeguard the piping, other valves, pumps, etc. if the flow changes. Water hammering may happen if the flow reverses and there is no check valve in place. A pipeline or other components can easily be damaged by a water hammer, which frequently occurs with great power.

Advantages

- Minimize chatter and the likelihood of unexpected valve failure.

- Fewer moving parts; reduced maintenance expenses.

- Ability to adapt to changing flow conditions.

Why They Could Be Used In Water Application

Various types of check valves for water are employed in a variety of settings. For instance, they are frequently installed on a pump’s outlet side to prevent backflow. Check valves are crucial for maintaining water pressure in the pipes since centrifugal pumps, the most prevalent kind of water pumps, are not self-priming.

Applications Of Water Valves

Types of water control valves have a wide range of applications. Their efficiency and adapting features make them a perfect fit in different areas. Valves can be used in distinct chemical plants, water management systems, water supply systems, and many more.

Different kinds of water valves have different applications and some of them have been mentioned below.

- Used In Chilled Water System

Chilled water control valves are crucial parts of fluid pipelines because they regulate the flow of a fluid by changing the size of the aperture through which the chilled fluid passes. The valve, an essential component of any fluid pipeline, controls the flow of fluid between the minimum necessary and the pipeline’s installed maximum capacity. These valves are frequently referred to as final control elements.

- Hot Water System

A valve is required to halt the water flow if the tank is leaking or needs repair without interrupting water delivery to the entire house, as well as when cleansing the tank to remove sediment collection at the bottom. The hot and cold pipes near the hot water system occasionally include shut-off valves.

- Wastewater System

The wastewater valve is the tool that controls the flow and pressure of fluids, including liquids and gases. Valves for wastewater treatment of various types allow varying amounts of fluid to pass through them. Many wastewater valves have simple designs. The flow meters and temperature gauges manage the flow meters.

- Water Distribution System

Values are an essential component of the water distribution system. These mechanical components have the ability to modify, direct, turn off, stop backflow, and control water flow in pipelines. Different types of water valves are specially created to meet a variety of requirements in the water distribution system. They can be created from a variety of materials, including copper, brass, and stainless steel.

How To Select The Right Types Of Valves For Water?

It is significant to be cautious while looking through the types of water valves and their functions. Moreover, keep in mind the purpose or application to avoid having to replace it anytime soon.

Additionally, there are a number of factors to consider when making the choice, including expenses and the valve’s entire service life in addition to functioning. Some of the significant factors that have to be kept in mind before selecting the perfect type of water valve have been given below.

Key Capabilities

First, consider the valve’s function. Compare the objectives with the fundamental principles and functionalities of the different types of water valves. This factor can be determined by defining the precise performance requirements for the system in which the valve should be installed.

For instance, if there is a requirement to install the valve in the water faucets, in such a case a globe valve would be the perfect choice due to its efficient regulatory feature.

Components And Qualities

The most crucial factor affecting the valve’s service life is the quality of the wedge, stem, and coating. Therefore, component materials used by the water valve manufacturers should be taken into account, along with their resistance to things like corrosion, porosity, and biofilm growth.

Even the slightest damage or degradation in the quality can lead to disruption in the entire system. Furthermore, lower-quality components might require frequent replacements making the valve more expensive.

Pressure Loss

It is essential that the valve results in either zero or the least amount of pressure loss feasible, especially in water systems. Any energy loss throughout the system will result in requiring more energy. This is because pressure loss is essentially a loss of the energy utilized to pump the water. Some of the valves might affect the pressure of the piping system, thus it is advisable to utilize them in scenarios where the system is not dependent on the pressure conditions.

Total Ownership Cost

It’s crucial to focus on the overall cost of ownership in addition to the purchase price when estimating a valve’s price. The total cost of ownership (TCO) includes all costs, including those incurred during installation, use, and disposal, or also the mechanical parts of the valves.

Dimensions And Features

Sizing the valve correctly is a crucial step in choosing the best valve for an application. It is important to think about temperature, flow, and pressure. Additionally, any demand for a certain actuation as well as regional market specifications, including design standards, testing, approvals, or certifications, might also be crucial considerations when choosing a valve.

Professional Water Valves Manufacturers - SIO

Valve manufacturer SIO specializes in the design and manufacture of industrial water valves, which are widely used in systems for the treatment of water and oil as well as other industrial systems.

The factory possesses certificates from API 6D, DNV CE, and ISO 9001. The production of SIO valves complies with engineering, quality, and safety standards that are created to meet the particular requirements of a certain sector. SIO valves are used in a variety of industrial sectors and are completely constructed in compliance with the standards set out by the sector. You can contact their team for more information.