Source: En.Siovalve

Valves are an essential part of the pipeline sector of the economy. Piping systems, in general, transfer useful substances that are needed in our day-to-day lives and are essential elements in many industries. It is vital for these systems to be made with quality products and caution to be able to withstand all the pressures they face. Butterfly valves are examples of the things they use in industries to facilitate operations and other things. This article highlights everything you need to know about butterfly valves from their advantages, functions, types, drawbacks, and the things you need to consider before purchasing. Read on.

What is a Butterfly Valve

Source: Pinterest

Butterfly valves are 90-degree rotary motion valves utilized in regulating, stopping, and starting the flow of media. They are valves that are easy to open, and turning the handles a quarter-turn will fully open or close the valve. The butterfly valve is usually used in systems where a positive shut-off is needed. You can describe the valve as a disk connected to a rod, and when the rod turns the disc (quarter-turn), the valve closes. The position achieved by this rotation is usually perpendicular to the direction of the flow. During the opening, you rotate the disk back to permit the flow of fluid.

The butterfly valves are usually popular since they have some features that make them desirable. Such features include a quick operation, being available in multiple sizes, cost-effective, lightweight valves, and having a small footprint during installation. The operation of these butterfly valves can either be through gears, automatic actuators, or operated using handles. Whichever way you choose, the valves are efficient and reliable for piping systems.

Most large valves usually have an actuator in the form of a gearbox, and the handwheel is normally connected to the stem through the gearbox. This arrangement reduces the force and speed of operation. You should install such a valve in the open position to prevent the rubber seat from wedging against the valve disc making opening difficult. Smaller valves are normally operated manually since they do not require a lot of force compared to the larger ones.

In terms of design, the butterfly valve can either be centric or eccentric. Centric valves have their stem at the center of the disc, which is in the middle of the bore. For the eccentric design, the stem usually one or two are not situated at the center of the disc. They are either double eccentric or triple eccentric.

Butterfly Valve Symbol

Source: Kindpng

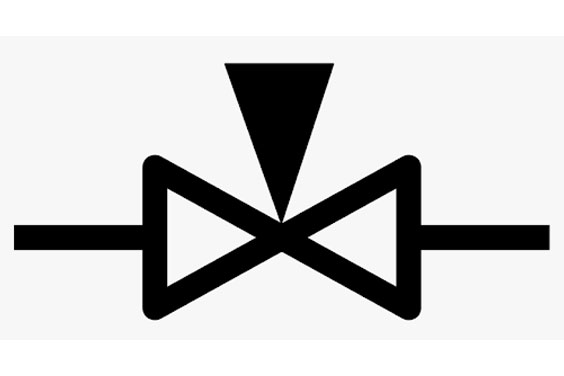

Symbols are usually used in the representations of different industrial valves. There are two major types of valve symbols; generic symbols and modifiers. Generic symbols are general, they only indicate the presence of a valve without specifying the type. Symbols with modifiers on the other hand show exactly what type of valve is used. The butterfly valve symbol is a bit different from the rest as it’s the only valve with an incomplete triangle on its symbol.

The symbol of the butterfly valve makes it easily identifiable among all the other valves.

Butterfly Valve Symbol

Source: Pinterest

There are various types of butterfly valves that are applicable in different situations. You can classify butterfly valves according to major categories, based on;

Disc closure design

How the disc closes will be categorized into either concentric or eccentric valves. The designs are as follows;

Concentric valve: it is among the most basic types of butterfly valve. Here, the stem of the valve passes through the midline of the disc. The disc is also situated at the center of the bore. The concentric valve is usually referred to as the zero-offset valve. The main application of this valve involves low-pressure and temperature applications.

If the valve is open, the disc splits the flow into halves making the disc parallel to the flow while being in the middle. The concentric valve has a very strong seat to enable its functions. Additionally, sealing in this valve is possible when the soft seat is deformed by the disc. Even with its various uses, the drawback of using the concentric valve is; usually, there is friction between the seat and the disc when the valve is in optimum use, making operation a bit hectic.

Eccentric butterfly valve: the eccentric actuated butterfly valve is opposite of the centric one; here, the stem passes away from the midline of the disc, making it an offset valve. There are three types of this valve;

- Single offset butterfly valve: it is where the stem is situated exactly behind the disc’s midline.

- Double-offset design: the stem is behind the midline of the disc as well but there is another offset on one side of the disc. The arrangement in the double offset creates an action that raises the seat out of the seal during operation. Opening and closing in this valve are easy since friction is minimal and only present during the first and last degrees.

- Triple-offset design: in this design, the additional offset is between the seat contact axis and the disc. It is a design that results in a very efficient valve that has minimal wear. The triple-offset valve is applicable in crucial applications. The triple offset also has a frictionless operation that ensures efficiency.

Based on Piping Connection

The piping connection is the design at the end of the valves where they connect with the pipes. According to piping connections, the types of valves are;

Butterfly valve flange type: in this category, the body of flanged butterfly valve has flanges that align with the pipe dimensions. This alignment makes it easy to connect the valve and the pipe without resistance.

Lug Type Butterfly Valve: it has legs that are protruding which have holes that align with those in the pipe flanges. There are metal inserts in the bolt holes of the valves. The lug butterfly valve is installed between flanges using different bolts. This design makes the valve easy to manipulate as you can disconnect one end of the line without any effect on the other one.

Wafer type butterfly valve: in this type, the valve is situated between two pipe flanges, and the valve body is surrounded by flange bolts. Long bolts cover both the valve body and the flanges. It is considered to be the most resourceful butterfly valve. This wafer butterfly valve is applicable in sealing services such as against pressure difference from two sources in the media flow while also providing a tight sealing.

Butt-welded valve: the butt-welded valves have welded ends. The end of the valve is welded to the pipe to facilitate its function. It is applicable in high-pressure applications that other valves might not be able to handle.

Based on Method of Control/Valve Actuator

How you operate the valves will also categorize them into different classes. There are two ways in which valves are operated; manual or hand-operated and automatic actuation. They are further categorized as follows;

Manual Actuation

A manually operated valve is one that uses hand-wheels/cranks to either open or close the valve. The operator has the ability to manipulate the valve however they want. These valves, however, cannot be applicable in major systems as they require more effort; hence they are mostly used in remote systems, especially those that don’t have access to power. For easier handling, a hammer/stem is connected to the hand-wheel making opening and closing effortless.

There are two types of valves under manual actuation;

- Lever-operated: it is a manual operation common in small butterfly valves. This type of control makes it possible to set the valve into three positions; open, closed, or partially open.

- Gear operated butterfly valve: these are manual operators utilized in small valves but a bit larger than the lever-operated ones. The gear is useful since it increases torque when there is a lower opening or closing speed. They are also capable of locking themselves. Additionally, you can install position indicators on the gear operated butterfly valve to make work easier.

Automatic Actuation

This method of valve control is very reliable as you can remote control the valves from another location and still be able to achieve your desired outcome. They are mostly applied in larger valve operations that manual controls cannot handle. There is a design of automatic actuators that can make them stay open if there is a failure in the actuator (fail-open) or stay closed if there is a failure (fail-close).

- Electric actuated butterfly valve : uses an electric motor to turn the stem of the valve. The electric actuator is the most preferred type when it comes to the handling of massive work and huge valves. They are very efficient since they are both automatic and use electricity as a source of power. Also, not so much work is needed in this type of actuator since all the work is done for you by the machinery. You only need to touch a dial and everything starts working according to plan.

- Pneumatic actuated butterfly valve: the pneumatic valve needs air that is compressed to move a diaphragm or piston so that it can open or close the valve. These valves are quick to action, hence, they are applied in open-close position and for throttle valves.

- Hydraulic operated butterfly valve: just as the name suggests, this valve requires a hydraulic to either open or close the valve. The hydraulic actuator results in a semi-automatic or automatic position of the valve. Hydraulic operated butterfly valves are mostly applicable in cases where a large force is needed to open the main valve. The spring in the system retains the valve in a closed position and fluid enters the chamber. It results in a change in pressure. If the hydraulic pressure is greater than the pressure of the spring, the valve opens. To close the valve, fluid is poured into the piston side and drained on the other side. These actuators are available in a variety of sizes at an affordable price.

Based on the Seat Material

A seat is a surface in the valve body that is in contact with the valve disc. It is a movable part in the valve that permits and restricts the transmission of media through the valve. The seat has numerous functions, some of them being the prevention of gasses, either combustion or compressed from getting into the manifold.

Soft seated butterfly valve: it means that one side of the valve is made of metal while the other side is made of a non-metal elastic material. It provides very good sealing; however, it performs poorly in high temperatures and wears out easily, especially in mechanical applications.

Metal seated butterfly valve: metal seated butterfly valves are made with metals on both sides of the seal. Although it is metal, they sometimes usually have poor sealing performance but are very reliable when it comes to resistance to temperature.

Difference between Seat Material;

- Temperature: soft seat material is applicable in a normal temperature environment, while metal seats can be applied at any temperature, whether high, low, or normal.

- Structure: most soft-seated materials are midline, while metal-seated is single, double, and triple eccentric valves.

- Pressure: soft seat is applicable in low to normal pressure, while a metal seat is applicable to medium to high pressure.

- Sealing properties: both types perform well in sealing, although the soft seat requires less manipulation to be efficient in sealing than the metal seats.

Advantages and Disadvantages of Butterfly Valves

Just like any other industrial valve, the butterfly valve has some benefits and drawbacks that are experienced in an industrial setting. Below is a preview of why you should choose the butterfly valve while still being aware of the problems you will face with it.

Advantages of the Butterfly Valves

- The structure of the valve is simple, making it a simple valve to handle during operations.

- It is convenient and can be operated frequently since the opening and closing is effortless. Also, there is low media resistance.

- You can achieve a good seal when there is low pressure.

- It is versatile, and its performance is easily adjusted.

- Media like mud can be transported through the valves without leaving much debris. It is a good feature that valves should have.

- It is straightforward to install the butterfly valve.

- The butterfly valves can be operated either automatically or manually, depending on your preference and the size of the system.

- The sealing material used is plastic or rubber, meaning the performance under low pressure is good.

- The structure of the valves permits labor-saving operations.

- Fluid resistance is small, especially when the valve is fully open.

- Non-metallic seats on butterfly valves are applied in chemical usage and other corrosive fluid.

Disadvantages of the Butterfly Valves

Even though the valve has many advantages, there are some drawbacks that you may face when using it. They include;

- There is usually poor sealing in the butterfly valve, and some work needs to be put into it to ensure there is a tight sealing.

- The temperature and pressure ranges are minimal during operations. Low-pressure ranges result in high energy consumption which in turn leads to a high cost of operation or production.

Butterfly Valve Function

Source: Pinterest

Every valve is made with an intended function, and for reliable butterfly valves, its main applications are;

- It performs well in industrial applications that involve high temperatures and pressures. The materials used to make the valve and its components permit it to work under such conditions.

- High temperature butterfly valves are among the best in dealing with media like slurry since their structure enables them to limit debris from this kind of media.

- They are also applicable in other media such as gasses, liquids, steam cryogenics, water, and so on. They are useful in applications like firefighting and vacuum.

- They are the best for throttling the flow of media.

Butterfly Valve Parts

Source: Pinterest

The butterfly valve is made of several components that collaborate to facilitate its function. The parts include;

1. Body Construction

The butterfly valve has a unique body construction contributing to its name. Although their design is unique, it is also simple. The closure component and the body shape are what make it known as the butterfly valve. The structure also makes the valve easy to maintain and repair. The body consists of a few parts such as ;

Valve body: the valve body fits perfectly in the pipe flanges. There are two valve bodies; the wafer and the lug. The wafer body is fixed using nuts and studs between the flanges. It has features like lightweight, economical in terms of installation and purchase, and lacks protruding legs. When handling the wafer body, take precautions during installation since some fail to form the seal properly. The wafer body is easy to replace and install.

On the other hand, the lug body’s legs are protruding, offering a surface for bolt holes that match those in the pipes. Separate bolts are used to install the valve between flanges. The lug body is beneficial in the butterfly valve as it permits downstream piping removal and dead-end applications.

2. Butterfly Valve Seat Design: the seat of a valve is a part that enables shutoff. To facilitate this function, the seat uses interference between it and the edge of the disk. The seat can either be locked, pressed, or bonded to the body. The seat is the part of the valve that different manufacturers design differently depending on their capabilities and creativity. However, the popular design is usually the single-piece versatile seat. If you use the seat in the application of line pressure, the pressure will cause the seat to deflect naturally according to the disc.

Valve can either be soft, metal or resilient seated butterfly valve. Metal seats have several advantages and feature making them suitable for industrial applications, they include;

- There is no jamming in the valve.

- There is a low torque in the metal seat.

- It is made with corrosion-resistant metal.

- It has good tightness.

- There is a wide temperature range when using this seat.

3. Valve Disk and Stem: the disk and the stem are also important elements in the butterfly valve. The disc is the part that halts the flow of media. Discs come in various designs and orientations. The stem world is close to the disk and consists of either a one-piece or two-piece shaft. The design of this part will help prevent galling potential in materials with rust-resistant properties.

4. Butterfly valve shaft: it is a motion valve that rotates a quarter-turn to either stop, start, or control the transmission of media. Some valves have gearboxes that simplify the work, although the speed is affected.

How Does Butterfly Valve Work?

Source: Pinterest

The butterfly valve works according to the fast shut-off principle. The disc in the valve is located at the middle of the pipe which permits a rod to pass through. The rod goes to the actuator which is on the outer side of the body of the valve. When using the handwheel, the disc rotates so that it can be perpendicular to the flow which opens a passageway for the flow or closes it depending on your intentions.

In the detailed description, the butterfly valve is a quarter-turn valve that can close and open when you turn the handles at 90-degree. Understanding the functions of the valve will help you understand its working principle. The primary function of the valves is to regulate media flow through the passageways. These valves are mostly used in waste treatment plants due to their features such as durability and reduced maintenance.

The metal disc is a vital component of the valve and its manipulation leads to either the closure or opening of the passageways. The butterfly/metal disc is situated on the rod and when there is the closure of the valve, it blocks the media from passing through. In the opposite state when the valve is open, the metal disc moves at a 90-degree angle opening the passageways and permitting fluid from passing through.

The operation also depends on whether the valve is fully or partially open. If it is partially open, it means there would be a restriction in the path of fluid flow restricting fluid from passing without resistance. Other components of the butterfly valve also contribute to the general performance of the valve. If they are all in optimum working condition, then the operations will be efficient and increase productivity.

In terms of operations, it is either done manually or electronically. Manual valves are operated using a lever and gears while the electric/automatic actuators are divided into pneumatic, hydraulic, or electric. The application of these actuators depends on the scale of the operations, the size of the valves, and other essential properties.

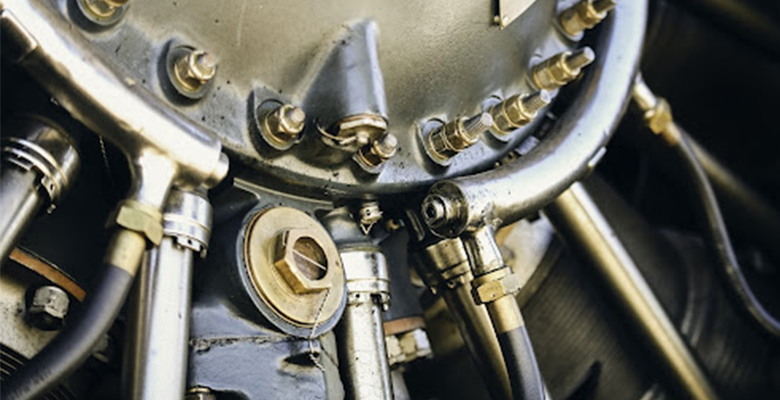

The butterfly valve can also be applied in automobiles. For example, you can find this type of valve in a car carburetor where it is utilized in the regulation of airflow to the engine of the car. When you use it this way, the valve will be partially open for maximum performance.

Installation and Maintenance

Source: Pinterest

Installation and maintenance of the butterfly valve are quite straightforward. There are some steps to follow to ensure everything is in order.

- You can start by cleaning surfaces, especially those that come in direct contact with the valve. Cleanliness will prevent the accumulation of debris and rust in the valve components.

- For orientation, you can install valves however you want but for maximum performance, an upright position is the best, especially when dealing with large valves. This position reduces the shaft load.

- Before any installation, always check the valve, disc, and seat material to make sure they are in good condition to prevent problems during operations.

- Always check the valve’s specifications to know what it can handle. If the valve ratings align with your application, then it is the suitable one to use.

- Any welding needed should be done before you install the valve. After welding, the valve and its components should cool first before installing.

- When attaching the bolts, be careful not to damage the seats, also, the faces should be aligned with the flanges to create space when the valve is open.

- Always remember to tighten the bolts to prevent falling off the valve after installation.

- After a successful installation, test the valve a couple of times to ensure it is ready for usage.

Maintenance of the valve is also simple, some of the practices include;

- Maintain regular usage of the valve since under usage also causes damage through rust and destruction of the operating systems. If you have no impending use, you can cycle the valve occasionally.

- Every time you want to do maintenance, remove the pressure first.

- Lubricate the valve regularly, especially if it’s working in dry areas.

- If you want to remove it from pipework, reverse the installation steps.

- Always follow the manufacturer’s manual every time you purchase a new butterfly valve.

- Moreover, avoid improper use of the valves like using it in an application with higher pressure than it can handle.

What to Consider Before Buying Butterfly Valves

Source: En.Siovalve

Before placing an order from high performance butterfly valve manufacturers, , there are some factors you need to consider. The main factors are;

Material

The material plays a vital role in the performance of the valve and also has an effect on finances. The durability of the valve will also be determined by the material selection. Popular valve materials used in valves are;

- Stainless Steel Butterfly Valve : stainless steel is an alloy of iron with some addition of chromium. The chromium helps in the formation of an oxide (chromium oxide) which forms a layer on the surface of the metal. If there is any damage on the metal surface, the chromium reacts with oxygen forming a protective layer preventing any rust from reaching the iron. This is a useful feature of this metal as it makes non-corrosive valves that are durable, like cast iron butterfly valve or carbon steel butterfly valve. There is a further classification of stainless steel which you can choose according to the valve applications. For valve manufacturing, the most preferred ones are duplex and austenitic stainless steel.

Austenitic stainless steel: this type contains additional elements apart from chromium. For instance, nickel is an additional element that adds more suitable properties for an industrial valve. Nickel has the effect of retaining temperature. It also gives the material additional strength and ductility. This type of material becomes applicable in cryogenic use.

Duplex stainless steel: this type contains both austenitic and ferritic iron. It is developed through a method that controls heat and the alloying components. It results in a material with higher strength and increased toughness. A superior product called the super duplex consists of more molybdenum and chromium to improve resistance against crevice corrosion and pitting.

- Bronze: this material is also an alloy but an alloy of copper and tin. A combination of these two materials makes bronze a very durable material with additional properties such as malleability. Being malleable means that any bronze butterfly will last long since it will not easily break. This material is also cost-effective and rust-resistant. You can apply this valve in applications that involve high temperature, high pressure, and those that deal with corrosive media.

Examples of these applications are water systems (hot and cold), compressed air procedures, utility applications, HVAC, gas systems, among others. Bronze is a very suitable material for making butterfly valves.

Furthermore, some bronze can also include lead and zinc in their alloys. If you need a bronze butterfly valve with these additional elements, you should be clear so that you get the one you need.

- PVC: polyvinyl chloride is a material that is used widely in many piping systems. PVC is a material that offers a variety of benefits to the valve. Some of the benefits are heavy-duty, low maintenance, lightweight, and the capability of various applications. Some of these applications are the production of gas and oil, in paper and pulp industries, air conditioning, marine, fuel management, refrigeration, petrochemical industries, and utilities.

PVC is a very suitable material to use in industrial valves. They have a high heat resistance meaning the valves can also be applied in situations involving a higher heat in the operations. If you are using this material in the production of butterfly valves, the design of the valve will either be lug design or wafer design.

Design

The design of the butterfly valve depends on its components. Each part will be developed differently depending on the services of the valve. The body, shaft, disc, and seat will vary from one valve to the other, distinguishing them for different types of applications. For body designs, the most popular ones are wafer type and lug type, although there are more designs. The lug body has lugs protruding from it, and they offer a bolting surface. For wafer design, the valve is sandwiched between flanges of the pipe. More design distinctions come from the disc, shaft, and stem.

Butterfly Valve Standard

Just like in any other industry, there are regulatory bodies that help govern manufacturers in the production of usable, quality, and safe products. In the piping industries, such organizations also exist to ensure valves are produced with all safety precautions in mind and to set the standard for manufacturers to follow. When choosing butterfly valves, you also need to consider such issues as certification and approval.

The popular butterfly valve standard are;

- ANSI: in full, it stands for American National Standard Institute.it is an independent organization that inspects and assesses the performance of valves to ensure they are fit for application.

- Uniform Plumbing Code (UPC): a UPC valve is one that is able to carry out various and complex applications. The shape of these valves makes them able to have low losses in load, very high ranges, and a high recovering factor.

- Underwriters Laboratory (UL): this organization tests the valves for a specific service and once approved, it becomes a UL listed valve. This type of valve means it can be able to perform the function it’s intended to, and you should not worry about safety issues or failures during operations.

Butterfly Valve Sizes

Valves come in several sizes that align with different applications and capabilities. By the operating features to perform the desired application and not by the size of the pipe diameter. The opening angle is considered when you want to know the size of the valve. If you are looking for a reliable fluid delivery operation, then choosing the right measurements for your valve is vital. The right size will improve efficiency by a high percentage. You can measure your valve with the following measurements:

- Diameter of side bore.

- The thickness of the seat.

- Height of seat.

- The outer diameter of the seat.

- The internal diameter of the seat.

All these measurements are usually in millimeters.

Butterfly valve sizing is the process of choosing the right valve for your application. Although the above are measurements for the valve, sizing requires a more detailed understanding in order to apply the right valve for the right application. You can do it by either determining pressure drop or by measuring the volume coefficient. The former is calculated by getting the difference between upstream and downstream pressures. Note that a big difference increases energy usage which in turn increases production cost. Volume coefficient is calculated using the pressure drop. The result you get will indicate the rate at which media is passing through the valve in a minute.

Working Pressure

The most common working pressure measurements are pressure nominal and PSI ratings. Before purchasing a valve for your application, you need to get conversant with these terms.

Pressure nominal (PN): it is the rate that shows approximate pressure rates. The rates show the pressure at which the particular valve is able to withstand. As a buyer, this is an essential property to look for when buying a butterfly valve to be sure of how much it can withstand during operations. Having this knowledge will help you prevent accidents, costly repairs, and wastage of time and resources.

PSI rating: Pounds per Square Inch is a unit representing pressure and is expressed in pounds of force in each square inch of an area. It is a unit used in various applications that involve pressure such as in a piping system.

Conclusion

Butterfly valves are valves that have many uses in an industrial setting. There are many things to know about the valve before committing to using it. These valves are manufactured by trusted manufacturers who put all their expertise in ensuring they are in good condition and of high quality to be effective. Whether it is a butterfly valve or reduced bore ball valve. At SIO, we understand that our customers need superior goods that will keep them ahead of the pack. We are dedicated to providing you with all your requirements in butterfly valves.

Contact us for more information and any inquiries about the butterfly valve.