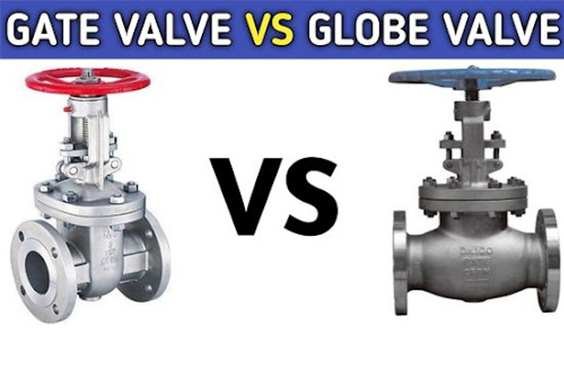

Globe valve and gate valve are two types of valves used in industrial applications. Both these valves have different advantages and disadvantages. Their main function is to control the flow of liquids or gasses in pipes or tanks. Globe valves can be used for both low-pressure and high-pressure applications while gate valves are normally used in low-pressure applications.

What Is a Gate Valve?

The flow can be started and stopped using the gate valve, but the flow level cannot be changed. They are, however, genuinely employed to separate or link liquids. Due to potential gate valve breakage and vibrations, some of the flow is not optimally regulated through the gate valve.

The name refers to the method of operation, which involves a gate sliding between valve seat perpendicular to the direction of fluid flow. The gate’s shape can be wedge-shaped, knife-shaped, or parallel.

Advantages of gate valve

- Gate valves have extremely little friction loss.

- They offer laminar flow with little pressure loss.

- Suitable for usage in high-temperature and high-pressure environments.

Applications of gate valve

- It permits goods to be delivered in a straight path with nothing in the way.

- Gate valves are very useful for stopping the flow of liquids when the partial flow causes irreversible damage to pipelines and systems.

What Is a Globe Valve?

The globe valve gets its name from the form of the valve body and can be used to initiate, stop, and modify the flow. During operation, the tapered plug enters and exits the fluid flow. The distance between the plug and the valve seat affects the flow rate. Operators must exercise caution to avoid damaging the valve seat by turning the valve stem too much.

Even when the valve is fully opened, it offers more resistance to fluid flow and has a higher pressure drop. Additionally, the bronze pressure regulator performs admirably when reducing pressure.

Applications of globe valve

- Water cooling systems

- Systems that run on oil.

- Chemical or feedwater systems

- Main steam vents and drains, as well as the boiler.

- Turbine lubricating oil system, among other things.

Advantages of globe valve

- Excellent shutdown capability.

- Moderate to excellent valve throttling

- Stroke lengthening (compared to a gate valve).

- The seats are simple to machine or resurface.

- It can function as a stop-check valve.

Globe Valves vs Gate Valves vs Ball Valves

Globe valves

Globe valves are used in low-pressure applications and gate valves are used in high-pressure applications. Globe valves are easier to install than gate valves. This helps you save time and money when it comes to installing your new valve, as well as making sure that the job is done right.

Gate valves

Gate valves are more durable than globe valves because they have stronger materials used in their construction, which means they’re less likely to crack or split over time (or even during installation). This makes them a great choice for long-term use or heavy-duty tasks like pumping water from an underground well or draining stagnant ponds!

However, if you need something that can withstand high pressures then you might want to consider choosing a globe type instead since this type of valve has been designed specifically for such situations where extreme forces may be applied onto them throughout their lifetime.”

Balls valves

Ball valves are a kind of quarter-turn valve that uses a bead-shaped ball with a hole in the middle to control the flow of media as opposed to gate or globe valves. The hole in the center of the ball, known as a bore or port, permits media to pass through the valve body when it is opened and is spun 90 degrees to halt the flow. When the valve is closed, the port is perpendicular to the valve body.

Globe Valves vs Gate Valves

Function

A globe valve is used to control the flow of liquids. The function is similar to that of a gate valve, which can also be used as a globe valve. However, the main difference between them lies in their construction and design. A globe valve has its own specific design that makes it easier for you to operate them without any difficulties whatsoever! You can even use your fingers if you want; no need for specialized tools or tools at all! Additionally, Globe Valves are extremely durable—you won’t have any problems with breaking them down after years’ worth of usage either! They’re also very easy and maintenance-free since there aren’t any moving parts within each component so everything stays intact until you replace it completely with new parts over time.

How Do They Operate?

The disc gets stuck between the seats of the gate valve’s operating mechanism. In terms of the media flow, its movement is at the proper angle. It offers either a complete flow or none at all. The flow space, where the stem and seats are placed, is almost equal in size to the valve cavity when it is opened.

On the other hand, the globe valve disc moves perpendicular to the media flow. The disc just needs to move slightly from its place when there is a complete flow. As may be seen in the second picture up top, its design permits throttling and tight cutoff.

Structure

Compared to globe and angle valves gate valves are used in the fluid flow direction of medium. This means that they can be opened or closed by rotating them sideways. Gate valves are classified into two types: rotating gate valves and non-rotating gate valves.

Rotating gate valves have a flexible shaft portion that rotates about a central axis when opened or closed by a pressure differential created between ports (or openings). The rotation of this shaft causes the movement of ports to open or close, respectively, allowing fluid flow through them under pressure control from one side port being higher than another (or vice versa). These motions may be reversed by reversing flow direction through the valve using its other port(s).

The Variation Between Sealing Surfaces

The screening surface of the valve is a little trapezoidal side of the valve core. The valve is said to have closed after the valve’s core has detached. On the surface of the valve disc, the gate valve is sealed. The globe valve effect is more powerful than the sealing effect.

Action

Globe valves manufacturers design globe valves to control pressure, while gate valves are designed to control flow. While both types of valves can be used in high-pressure applications, they’re best suited for different tasks.

Gate valve applications include:

- Low pressure applications (less than 100 psi)

- High flow rates (more than 100 GPM)

Price

The price of a globe valve is higher than that of a gate valve. This is because they are made with different materials and in different sizes, so the cost will vary accordingly. The price of a globe valve depends on:

- Material (ceramic vs stainless steel)

- Size (smaller or larger)

- Brand name

Material

The material used in a valve has a significant impact on its performance. A valve can be made from carbon steel, stainless steel, or alloy steel. In general, carbon steels are cheaper and lighter than stainless steel but they bend more easily and require more maintenance due to their higher sensitivity to temperature changes. Alloy steels provide the best balance between cost and performance because they’re stronger than either pure carbon or plain chrome-molybdenum alloys (which are commonly used as alternatives).

Pressure Drop

The pressure drop is the difference between the total pressure and the residual pressure. It is a measure of how much energy is lost through a valve. The flow rate, or how fast water flows through a pipe, affects this loss of energy.

Smaller valves have less loss of energy because they don’t require as much pressure to open or close in comparison with larger pipes that might take longer to fill up with water before starting to flow again after being opened up fully by an operator who has turned off their hose sprayer before entering into work mode (or vice versa).

In Terms of Their Use

Gate valves and globe valves are used in different industrial applications and have their own advantages and disadvantages. Gate valves are mainly used for high-pressure applications with a maximum operating pressure of 70 bar or higher, while globe valves are more commonly used for low-pressure applications with a maximum operating pressure of 50 bar or less. They can also be found on smaller vessels such as pumps, water meters, and chemical tanks among others. The main difference between globe valves and ball valves lies in their design characteristics: Globe valves typically have an integrated hinge allowing them to be opened when needed without having to manually remove them from their housing; whereas a gate valve requires manual removal because its body contains multiple parts that must be detached before opening it.

Conclusion

Gate valves and globe valves have different applications and are used in different industries. As a result, you should choose the right type of valve for your specific needs from the gate valves manufacturer and globe valves manufacturer .