Water management is a significant factor and clean water can be accessed with the help of wastewater treatment. The wastewater piping systems consist of wastewater valves that control the movement and pressure of the fluid. There are different types of valves used in wastewater treatment, some can be easy while some are complex to use. Moreover, different valves have varying degrees of allowing the flow of fluids or gases.

What Is A Wastewater Valve?

A waste water valve is a valve that controls the fluid flow or gases. The flow meter and temperature gauge determine the functioning of the valve.

Furthermore, these valves restrict the waste and unclean water to pass through, allowing only the flow of clean water. There are different types of wastewater valve that has distinct functions and features.

Moreover, each of these wastewater valves has a specific function to perform in wastewater treatment. The valves provide a complete shutdown or closure when required. Most of them are operated manually and also help in preventing unwanted leakage.

What Are the Different Wastewater Valve Types

The valves used in wastewater treatment are available in various types, some of which include ball valves, butterfly valves, plug valves, globe valves, and many more. Such distinct wastewater valve types have been mentioned below.

1. Check Valve

Waste water check valve controls the flow of fluid by isolating or regulating it. The check valves enable the movement of fluid in one direction, thus there is a minimum to no chance of fluid backflow. In case, the liquid flow revers, the valve instantly shuts down and isolates it from the main piping system. They comprise a circular disc located towards the center of the valve to regulate the flow.

Furthermore, wastewater check valves operate efficiently in high-pressure systems as compared to low pressure. One of the beneficial aspects of waste water check valves is that they do not require manual operations. They are self-automated and cost-effective choices. Although large in size check valves are light weighted and appropriate for usage in pumps and processors.

The major drawback of wastewater check valves is that work effectively in the piping system with continuous water flow. For the ones that have a periodic flow, check valves might not be a suitable option.

2. Ball Valves

This ball-shaped element is located in the seat inside the valve. These valves are open or close by semi-turning movement. The movement of the ball restricts the flow of the liquid allowing a uniform seal. When the valve is open the ball enables swift movement of the fluid through it.

The ball valves play a significant role in controlling the pressure and flow of the liquid. Moreover, these valves prevent leakage and also fluid movement from a lower compressed air line toward the higher hydraulic systems. The distinct features of the valve make it easy to use and maintain.

Due to their high withstanding capacity in terms of pressure, temperature, and velocity, these valves are more commonly found in shipping systems and chlorine manufacturers. The only issue might arise in cleaning these valves. Therefore it is advisable not to use ball valves in the pharmaceutical or food and drink systems.

3. Gate Valves

The primary function of the wastewater gate valves is to prevent and regulate fluid flow. Gate valves are also known as full-stop valves. While the system is functioning the valve remains open allowing the liquid like wastewater to pass through. In reverse conditions, the sewage gate valve restricts the flow of the liquid completely with the help of the gate closure.

The wastewater gate valve are only utilized for controlling the flow of the liquid, and not to adjust the pressure as it might lead to their damage. Furthermore, it can function efficiently in high pressure and temperatures. The common application of this type of valve is in the wastewater

treatment, pharmaceutical industry, manufacturing systems, and automotive sector.

4. Butterfly Valves

A butterfly valve is similar to the ball valve as it uses the half-turn mechanism to operate. There is a series of centrally-located flaps used to open or close the valve. The handle of the valve is attached to the stem which is further connected to the disc placed inside the valve. The movement of the handle causes the disc to rotate and open or close the valve. This type of valve can be further categorized into three types: double eccentric, concentric, and triple eccentric.

They are a convenient choice to restrict and regulate the liquid flow. Moreover, it is an appropriate option for pipes with a greater diameter. Moreover, its compact, lightweight design allows plenty of space for other equipment. The major drawback of this type of valve is that it can lead to a drop in the pressure due to the presence of a disc inside the valve.

In secondary and tertiary treatment processes, when organic matter is eliminated by a suspended growth process and, correspondingly, chemical treatment, they often take center stage. Power-actuated control valves, commonly wafer butterfly valves, and high-power centrifugal air blowers are frequently used in aeration systems.

Processes used in tertiary treatment can range from biological to chemical, including tertiary filtering, effluent disinfection, and dechlorination of the final output water before it is pumped for reuse or released into a river.

Because of their small size and inexpensive price, butterfly valves made in line with AWWA C504 are frequently employed here, especially for large pipe sizes. For this service, quarter-turn butterfly and ball valves are both dependable and easy to automate.

5. Globe Valves

Globe valves sphere-shaped valves are divided into two halves separated by an internal baffle. Their main function is to limit the fluid flow. Thus there are minimum chances of leakage. They have been designed to start, limit or restrict the movement of the liquid. These valves might lead to a higher pressure drop as compared to other valves.

Thus it should be used in piping systems where pressure does not play a major role. The application of these valves is in food processing and wastewater management facilities. It can also regulate the fuel oil systems and be used in chemical processing units.

The flow via a globe valve has a cyclical motion: the fluid enters the valve parallel to the valve port and exits the valve after two 90° spins, exiting the valve once more parallel to the valve port. When the globe valve is fully opened, the disc (plug) can completely block the flow passage, or when the valve is fully closed, it can completely seal the flow path. The globe valve seating is parallel to the line of flow. By altering the size of the port aperture through which the fluid flows, a globe valve controls fluid flow. This is accomplished by moving the disc (plug) perpendicularly away from and toward the valve seat in order to change its position.

6. Plug Valves

Similar to the ball valves, the plug valves also operate by half-turning the plug which further allows or prevents the flow of the liquid. These types of valves are a great option for commercial and industrial sectors.

Their smooth design, low maintenance, and leak-tight service make them an appropriate fit for several sectors. Moreover, the plug valves have higher durability and corrosion resistance. The versatility of these valves allows even a larger flow of fluid.

The foundation of a plug valve is a plug with a hollow tube in the valve body. The alignment between the pipe and the hole is produced by the quarter-turn motion, resulting in an open condition. The valve rests across the pipe that leads to a closed state when it is turned to a 90-degree angle from the open position. The valve rests across the pipe that leads to a closed state when it is turned to a 90-degree angle from the open position. There are numerous styles and port openings available for plug valves:

- Two-Way Plug Valves: This design enables both a straight-through, two-way service for the open and close function, as well as a closure element in the middle (a plug and a sleeve).

- Three-Way Plug Valves: These valves have a third port, which usually faces away from the inlet at a right angle. These plug valves can assist with flow combining or diverting.

7. Non-Return Valve

A non-return valve is used to prevent reverse flow in situations where pressure circumstances may otherwise result in it by allowing a medium to flow only in one way through a pipe. When constructing the system, it is important to consider the relatively significant pressure drop that the flow via the non-return valve creates.

Non-return valves come in a variety of designs, including spring-loaded, swing-type, and clapper valves. Non-return valves are used in home wastewater systems to avoid backflow and with mixing loops in heating and cooling systems to ensure proper operation.

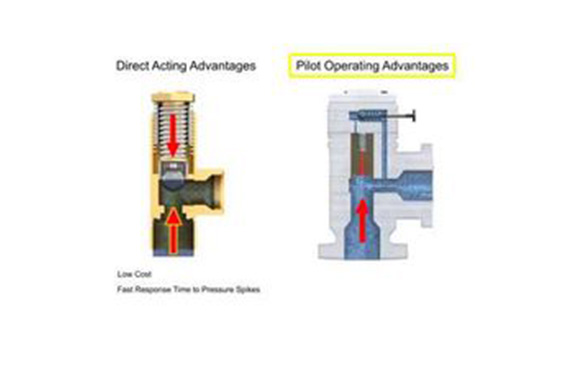

8. Pressure Relief Valves

A pressure Relief valve is a type of safety device used to guard a pressurized system or vessel from overpressurization. Any circumstance that could raise the pressure in a vessel or system over the designated design pressure or maximum permissible working pressure is referred to as an overpressure event (MAWP).

A pressure Relief Valve’s main function is to safeguard people and property by releasing fluid from an overpressurized vessel.

There are numerous electrical, pneumatic, and hydraulic systems in use today that regulate the pressure, temperature, and flow of fluid systems. Each of these systems needs some kind of power source to function, such as electricity or compressed air. A pressure Relief valve must always be able to work, especially during a power outage when system controls are inoperable. Therefore, the process fluid is the only source of power for the pressure Relief Valve.

The pressure Relief Valve is the sole device that can stop a catastrophic failure once a situation arises that causes the pressure in a system or vessel to rise to a dangerous level. The design of the pressure Relief Valve is as straightforward as feasible because device complexity directly affects reliability.

When the system pressure reaches a safe level, the pressure Relief Valve closes. It must also open at a predetermined set pressure, flow at a specified overpressure, and close at a planned set pressure. The materials used to create pressure relief valves must be suitable for a wide range of process fluids, from the least corrosive media to basic air and water. Additionally, they must be built to function consistently smoothly, and steadily across a range of fluids and fluid phases.

9. Solenoid Valves

Solenoid valves are utilized in applications where fluid flow must be controlled automatically. They are being utilized more and more in a wide range of plants and machinery. Solenoid valves are control devices that, depending on whether they are electrically activated or deactivated, either shut off or permit fluid flow.

The actuator is an electromagnet. A plunger or pivoting armature is pulled by an electrified magnetic field in opposition to the force of a spring. The plunger or pivoting armature is brought back to its initial position by the spring action when the device is de-energized.

Why Valve Plays An Important Role In The Wastewater System?

The main purpose of the wastewater system is to collect the wastewater emitted from industrial or residential areas. The wastewater is processed into the final outflow and the freshwater passes through the piping systems. The valves should be placed appropriately inside the piping system to enable efficient wastewater treatment.

There are a lot of non-operational pumps and piping systems through which the wastewater might flow. The valves prevent the fluid from flowing into these piping systems. However, it is essential to consider that the valves are appropriate for the different types of fluids comprising unwanted materials.

Most industries and commercial places include unwanted corrosive elements that can pollute the water leading to wastewater. Therefore, the placement of the valve isolates and controls the flow of liquid. Be it the protection from the abrasive elements or protecting the infrastructure of the piping systems, the valves can do it all. Different valves perform different functions in wastewater management and different industries.

- Control Valves: These valves play an important role in stabilizing the different processes. It provides reliable control over the flow at the same time increasing sustainability and maximizing the productivity of the industries.

- On-off valves: These kinds of valves prevent and reduce unwanted emissions. They provide a long-lasting shut-off and maximum safety for the different piping systems.

How To Select The Types Of Valves Used In Wastewater Treatment?

It is significant to select the type of valve that is efficient and safe to use in wastewater facilities. The one with the lower maintenance and higher proficiency should be selected. Besides the efficient features, it is also necessary to consider the purpose, reliability, and accuracy of the valves.

Some of the factors that should be considered before selecting a valve for wastewater treatment are:

1. Components Used In Construction

Understand the standards for chemical compatibility. The materials used to construct the valve must be compatible with the liquids that pass through it. Plastic valves typically outperform metal valves in terms of resistance to corrosive or harsh substances.

2. Prerequisites For Performance

Determine the necessary pressure and temperature. The temperature and pressure ranges at which the valve will be fitted should be determined. In comparison to plastic valves, metal valves often endure higher temperatures and pressures. The finest valves for pressured elements are often made of metal. They are typically more durable than plastic valves.

3. Maintenance

The need for maintenance should be taken into consideration while selecting any valve. Both valve dependability and application stability depend on this. They withstand jamming, clogging, and malfunction. However, they are ineffective for changing flow. They may leak or fail before their time is used to control flow. The ease and speed of repair or replacement depend on the valve connection type. There are advantages and disadvantages to each connection style.

4. Wastewater Treatment Valves Must Meet Specific Criteria

Ascertain that the new check valve performs as planned. Consider both the cracking pressure and response time needed to open the waste water valve.

The distinction between normally closed and normally open is another factor. Simple check valve configurations need positive downstream pressure to open. Common names for them include normally closed valves. Other designs need strong backpressure in order to close. Typically, these are referred to as normally open sewage valves. Between these two options, making the right decision can increase check valve efficiency.

When making this choice, it is typically appropriate to consider whether the sewage valves are typically more open or closed during regular system operation. If installed vertically as opposed to horizontally, some wastewater valve types might not function properly. For water treatment valves designs that can be installed vertically, fluid density and flow direction (upwards vs. downwards) are also important factors.

Professional Water Treatment Valves Manufacturer - SIO

Valve manufacturer SIO is one of the leading suppliers producing high-quality valves. The wastewater valves they manufacture are not only reliable but also cost-effective. The premium quality industrial valves manufactured by them have multiple applications and specifications.

The wastewater valves are one of their specialties that can be a perfect choice for any kind of wastewater treatment. Contact SIO for more information.