A pressure reducing valve, or PRV, is a valve that reduces the pressure of liquids and gases in a piping system. The primary purpose of a PRV is to maintain consistent system pressure despite variation in demand or climatic conditions. Learn how a PRV works and find out if one is right for your application.

How Does A Pressure Reducing Valve Work

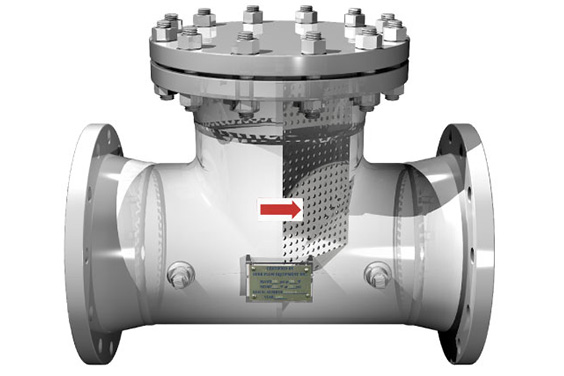

A pressure reducing valve (PRV) is a valve that automatically controls the pressure of a fluid. PRVs are used in a variety of applications, including in residential and commercial plumbing, as well as in industrial and process piping systems. A PRV typically consists of a body with an internal seat, a diaphragm, a spring, and an adjustable knob.

When the knob is turned to increase or decrease the pressure, it adjusts the tension on the spring, which in turn regulates the flow of fluid through the valve. In this way, the PRV can be used to maintain a constant pressure within a system, regardless of changes in demand or supply.

- The pressure reducing valve is designed to maintain a constant downstream pressure regardless of the upstream pressure.

- The pressure reducing valve can be used in systems where there are changes in elevation or when there are large variations in flow rate.

- The pressure reducing valve will control both the upstream and downstream pressures by regulating the amount of fluid that passes through it.

- When you install a pressure reducing valve, you must make sure that the downstream side does not exceed the maximum working pressure for your system.

How do you adjust a pressure reducing valve?

Adjusting a PRV is a simple process, but it is important to exercise caution and follow all safety instructions when working with valves and plumbing components. First, locate the PRV and identify the adjustment screw.

This screw is usually located on the top or side of the valve body. Next, use a wrench or other tool to turn the adjustment screw clockwise or counterclockwise to increase or decrease the pressure, respectively. If you are unsure about how to properly adjust a PRV, consult a qualified plumbing professional.

At what PSI do you need a pressure reducing valve?

The answer depends on the specific system you’re using. Each system has different pressure requirements, so you’ll need to consult with your manufacturer or engineer to determine the correct PSI for your PRV. In general, however, most PRVs are designed for pressures between 40 and 60 PSI. If your system has a higher pressure than this, you may need a special high-pressure PRV.

Installing a PRV is an important step in maintaining a safe and efficient pressurized system. By understanding the correct PSI for your PRV, you can ensure that your system stays at optimal performance.

How does a pressure reducing valve work in a hydraulic system?

A pressure reducing valve is a type of safety valve that is used to regulate the pressure in a hydraulic system. The valve is typically installed between the pump and the reservoir, and it is designed to open and release pressure when the system pressure exceeds a safe level.

Pressure reducing valves are an important part of many hydraulic systems, as they help to protect the system components from damage due to excessive pressure. When the valve opens, it allows oil to flow back into the reservoir, which lowers the system pressure.

Pressure reducing valves are typically set to open at a specific pressure, which is determined by the system designer. Once the valve opens, it will remain open until the pressure drops below the set point, at which time it will close again.

How does a 3 way pressure reducing valve work?

A three-way pressure reducing valve is a type of water pressure regulator that is typically used in commercial and industrial applications. Unlike a traditional single-stage pressure regulator, a three-way pressure reducing valve has three ports: an inlet, outlet, and feedback port.

The feedback port allows for the installation of a differential pressure gauge, which can be used to monitor the pressure difference across the valve. When the inlet pressure rises above the preset level, the valve opens and starts to regulate the flow of water through the system.

This prevents damage to equipment or pipes that could occur if the water pressure was allowed to get too high. Once the inlet pressure has been reduced to the desired level, the valve closes and stops regulating the flow of water. This type of valve is often used in applications where it is important to maintain a constant water pressure, such as in irrigation systems or fire sprinkler systems.