Stainless Steel Valve Company

Stainless steel valves are revered for their ability to withstand chemical exposure, high pressure, and harsh temperatures. Pharmaceutical, oil and gas, and power generation industries prefer stainless steel valves in their operations as they boast on their revered durability, versatility, and strength.

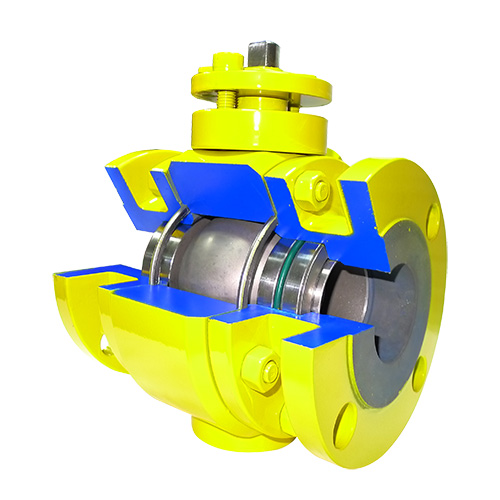

By opening, partially obstructing, or closing various passageways, stainless steel valves are used to regulate, direct, and control the flow of fluid. Stainless steel valves are commonly used in irrigation, military and transport sectors, residential purposes, and processes for industries.

Manufactured from the highest quality materials, stainless steel valves are the ideal choice for applications that require corrosion resistance. They also have very high resistance to leakage, making them an excellent choice for demanding applications that are exposed to high amounts of temperature and pressure.

SIO Stainless Steel Valves are made to meet the needs of every customer. SIO Stainless steel valves can endure harsh temperature, high pressure, and exposure to various chemicals.