Source: Unsplash

In an industrial setting, versatility is a characteristic that is valued. Valves are the flexible components of piping systems as they allow efficiency and functions that would have otherwise been very costly or impossible to achieve. There are many types of valves, and with the improvement of technology, more advancements are required to facilitate new piping systems that enable various functions. The three-way valves are among the most vital valves you can have in your company.

This blog post focuses on the details about 3-way valves and everything you need to know before deciding on the valve choice for your pipelines. Let’s dive in.

What is a 3-Way Valve?

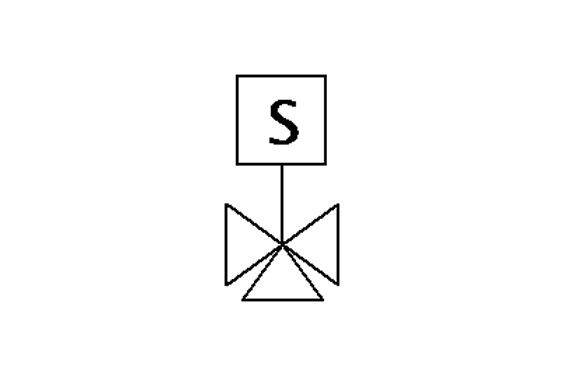

Source: Siovalve

A valve is a device used in industrial settings to regulate the flow of fluid, that is, gasses and liquids. Fluids flow under pressure among the multiport valves. The openings/ports can either be two inlets and one outlet or two outlets and one inlet; it depends on the direction of the fluid flow. The 3-way valve is popular compared to other ball valves because it’s affordable and serves both as a shut-off and a direction controller. For a 3-way valve, there is a metal ball on the connection between the openings. This metal ball has orifices that control the flow of media.

The ability of 3-way valves to mix gasses and liquids from multiple inlets makes it the best option for cooling and heating media such as oils, chemicals, and water. They are also used as bypass valves in loop applications (primary and secondary). Additionally, 3-way valve construction is done with premium materials since the valve needs to be strong enough to withstand the pressures of its functions.

The most preferred metal used is stainless steel, as it is a reliable and durable metal. Every 3-way valve must be high-performance and dependable to handle its applications well. Apart from being known as a 3-way valve, there are other names that refer to it, such as a bypass valve, constant flow valve, mixing valve, among others.

In general, three-way ball valves are able to solve challenging flow issues than any other valve. They are very useful in numerous industrial applications. For instance, in the food and beverage industries, you can employ the valves to mix juice concentrate and purified water from two different sources. Another example; is a diverting valve in the fuel industry where you could divert the flow of fuel from one tank to the other and still be able to shut off the flow if need be.

What is a 3-Way Valve?

Source: Gallery

There are various types of valves in an industrial setting, and for proper representation, symbols are employed to differentiate the various valves. There is a system used to give these valves symbols, it is explained below.

A square is used for every state of the valve. For instance, a 2/2 valve has two states; it is open and close; therefore it is represented by two squares. Arrows are used on each square to show the direction of the flow and also to show which ports are connected. Closed ports are identified by the letter ‘T’. For showing activation states, an actuator symbol is used on both sides of the square. On the right side, a spring will show the valve is in a rest state, and on the left side, a solenoid symbol identifies an energized state.

Additionally, numbers are used in valves to show the connection ports and the switching states. The first number indicates how many connection ports are present on the valve, while the second number is for the switching states. Other symbols include the normally closed or normally open states. NC and NO represent each respectively to show if the valve is open or closed in de-energized mode.

Types of Three-Way Valves

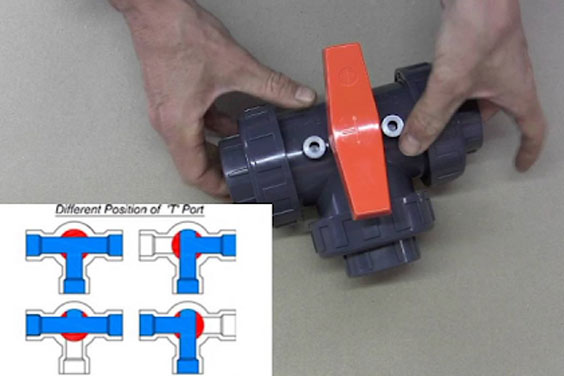

Source: 5iming

There are two types of three-way valves; the L port and the T port ball valve. These valves have different applications and types. The valves are named according to the shape of the opening in the ball valve. In some instances, the three-way valve types can also be categorized as 3-way normally closed or normally open solenoid valves. Moreover, the general categorization of the 3-way valve is described according to the following;

- Flow pattern; either the L-pattern or the T-pattern. The valve’s passageway is shaped like an L in the L-port and like a T in the T-port.

- Orientation; is how the handle is oriented either vertically or horizontally. The orientation also affects the overall performance of the valve.

- Positions; the number of turns the handle rotates. There are three positions; 90-degree (two-position), 180-degree (three-position), and the 270/360-degree (four-position).

L Port Valve

Source: Image

The L-port 3-way valve is popularly known as the diverting valve. They have flow paths in the shape of an L forming a 90-degree angle. The angle allows flow from one inlet and directs it into one of the outlets. The main purpose of an L port valve is to direct different media from several sources. The handle turn in the valve can change the connection and block one tank to draw from the other one.

In a manual 3-way L-port valve, the diverters are normally situated at the bottom part of the body as the flow entry or as the common port. The l-port can be further categorized according to the rotating angles or positions. The two-way L-port valve has a quarter-turn creating two positions. The rotation can either be a right turn or a left turn of the handle.

When you add an additional turn to make it a half-turn (180-degree), the flow also stops and it acts as a shut-off valve. This position is referred to as a three-position. The valve can have a further rotation of a 270-degree and 360-degree turn. The L-port valve has two possible shut-offs.

Moreover, for horizontal L-port valves, their handles are limited to the half turn (180 degrees). This feature allows various flow options; right flow, left flow, and the cust-off the flow. It is also a three-position valve due to the number of turns it can allow.

The vertical L-port valve, on the other hand, the common port is always open. A 180 turn on this valve will cause a diversion to the left or the right. The flow here is cut off if the rotation is a 90-degree one. The handle will face the front or the back of the valve. Similar to the horizontal valve, the vertical L-port valve also has three options, right flow, left flow, and one-off position.

Application of an L-Port

- The L port diverts the flow from one source to another source. Diversion is the primary function of the L-port valve. It is very useful in industries that deal with more than one media as the transmission process will be easy.

- It has the ability to divert flow from two storage tanks. You can transmit more than one fluid from different sources using the L-port valve. If you don’t need any mixing, this is the right valve for you.

- If you want to avert from a free cooling to a chiller, then the L port is the way to go.

- You can switch between two separate pumps using the L port. You don’t have to disconnect every time you want to transmit fluid from a different pipe. The working mechanism of an L-port valve permits the change easily.

T Port Valve

Source: Image

The T port valve is the valve referred to as the mixer or, better yet, the 180-degree valve. It can also transfer media from one source to another by aligning the T lines with the valves so all the ports can mix up. You can also direct opposite flows from one source into two places simultaneously. The valve can also be used to direct flow between two ports, to the left, right, or straight.

The T-pattern valve is sometimes used as a diverter, meaning it can work as an L port as well. It is done by a 90-degree turn of the handles. Even with all these functions, the T port cannot offer a bubble-tight closure (shut-off); however, they still limit the flow to the two openings or can permit passage to all the other three ports. For a vertical T port valve, the standard port is usually open; the only way to divert the flow is turning a quarter turn since the 180 turns will not divert the flow of the fluid.

The T-port 3-way valve also can change flow with the turns of the handle. For instance, the motion of the handle can either result in a diversion flow, split flow (mixing), or a straight flow. The t-port also has horizontal and vertical valves. The horizontal T-port valve has four flow paths from the quarter-turn to the full turn.

The vertical one is a bit different from its counterpart. The common/bottom valve is usually open and turning the handle at 180-degrees does not affect the transmission path. However, if you rotate the valve at 90-degrees and the handles face the back or front, the flow will cut off completely. The vertical T-type valve is mostly limited to either a quarter-turn or a half-turn. The flow options for this valve are flow cut-off and flow between the three ports. The other name for vertical T-pattern valves is tee port valves (Valves with tee port balls).

Application of the T-Port

The following are the general application of the T port valve;

- They blend flow from various sources. Not every valve has the ability to blend flow, it is a unique feature of the T-port valve.

- T-ports are able to split flow between various destinations.

- They alternate flow between two sources to make it more efficient.

- As the mixer valve, the T-port valve permits blending from two sources. You can use this valve if you are dealing with different media that need mixing.

- There is a possibility of an alternate flow between two destinations.

3-Way Normally Open Solenoid Valves

This kind of solenoid valve has three pipe connections; the stop port, body cavity port, and the body orifice port. The open feature comes in with the orifices, the stop, and the body orifices, and one is always open. This feature permits two paths of flow. It works by; the plunger raises when the power goes off which closes off the stop opening, and the body orifice opens up. After opening, the media flows through the valve to the cavity port.

If there is power, the plunger goes down and seals off the body orifice, and opens up the stop orifice. This action creates a passageway of media to flow from the cavity port to the stop port.

3-Way Normally Closed Solenoid Valves

Same as normally open, the normally closed valve also has three pipe connections and two orifices. It works opposite of the normally closed one, here, when the power is off, the plunger drops and seals off the body opening and opens up the stop opening. Media then flows through to the stop port from the cavity port and when there is power, the plunger goes up and closes off the stop opening and the body orifice opens permitting flow out through the stop port.

3-Way Directional Control Solenoid Valves

This valve has two orifices and three connections. One of the orifices is always open, allowing a double path of flow. When the power is turned on, the plunger lowers or raises, sealing off the stop orifice and opening the body orifice. The media is then directed through the body of the valve. When the plunger has dropped, the body orifice closes and the stop orifice opens directing media via the port.

Advantages of the 3-Way Ball Valve

The three-way valve has some features that make it advantageous compared to other valves. Its features permit it to be applied in various ways. The features are as follows;

- It is a self-cleaning valve, meaning maintenance will be cost-effective.

- The valves have no friction making closing and opening easy.

- It is single-seat, eliminating any influence the media has on safety.

The three-way ball valve has the following advantages;

- Total shut off: the 3-way ball valve has the ability to completely shut off the valve when the need arises.

- It has the capability to mix two different fluids making work easier in an industrial setting.

- The valve is able to divert the flow of fluid to another direction. The handles in the valves help with the diversion.

- The 3-way valve can also split media flow into two directions.

- Additionally, the valve has the ability to cause blockage of one fluid and permit another one to flow in the initial direction.

- How the valve is made provides low resistance of the media passing through it.

- The maintenance of the valve is simple and uncomplicated.

- The valve is made in various sizes, increasing its applications. The size of the valve is vital for alignment when connecting with the pipes.

3 Way Valve Function

The three-way valve is a versatile valve, meaning it has several functions and is applicable in various situations. The 3-way valve functions are as follows;

- Flow diversion: the valve functions as a flow diverter as it has the capability to change the course of flow.

- 3-way valves can completely shut off flow when there is a need to stop the flow of media.

- If you need to mix with different media, then this valve is the best for the job. It can mix the flow from two different locations and directly into one.

- You can switch flow from two directions.

- They are used in flow volume variation.

- They can also be applicable in flow with temperature variation.

- The 3-way valves are essential in primary and secondary pumping systems.

- For two and four-pipe distribution systems, 3-way valves play a vital role.

A three-way valve is an essential tool in industries dealing with piping systems. They are used in closed-system applications and other important uses.

How Does a 3-Way Ball Valve Work?

Source: Image

In a piping system, various fluids will be needed at different times and locations. Valves are the easiest way to ensure there is no wastage of fluids or time by directing the correct media to the right destination. These valves work by various mechanisms depending on the type and abilities. 3-way valves are the most preferred valves since they are very efficient and serve a couple of functions making the whole process easy and cost-effective.

The working principle of the three-way valve starts when the fluid flows in the passageways from different sources. The fluid will be cut off from each other or mixed, it all depends on the operator’s intentions. The valves start by turning mechanical valves (handles) or activating electric ball valves (actuators). This action rotates the ball inside the valve body, hence resulting in an alignment between the channels and the openings of the valve to direct the flow.

The L shape in an L port directs the liquid/gas from one port to the other through a 90-degree angle. On the other hand, the T shape on the T port directs from one port to another but can also rotate to align the T with the T shape to mix all three ports.

In simple terms, the valve works through the following principle; the valves open and the fluid enters the valve through the first port, ‘A’, it then flows out through port B. The bypass then triggers the actuator to open when the media is required to flow in. The valve core is hence reversed and the fluid enters C. If there is no need for media to flow in, the actuator is unblocked and the valve cuts off the fluid.

The working principle of the 3 way valve also depends on the function you want to carry out. The L and the T port valves serve different purposes hence their working mechanism although similar, have some slight differences to facilitate their different functions. Any inappropriate use of any of the two valves will lead to vibrations, water hammering, damage mage to the piping systems, and chattering.

Which is the Right 3-Way Ball Valve for You?

The best valve for you will depend on your applications. If you need a valve for shutting off ports at any step of the procedure, then the L-port is the right fit for you. On the other hand, the T-port valve is applicable if you need to mix all three flows.

How to Manipulate the T-Port to Shut-off Flows

If you want to shut off every flow on a T-port valve, you need an extra valve where you will add it to the opposite sides of the T-port valve. To shut off the flow, close the two additional valves and turn the ball in the 3-way valve to face the rear side.

How to Tell Direction of Flow

It is quite simple to know the direction of flow on the 3-way valve as it is indicated on the valve. There is a T-shaped arrow on the handle that imitates the cut-out of the ball inside, this indicator shows the directions of the flow.

How to Mix the Flows Properly

To mix the flows properly in a 3-way valve (T-port valve), you need to ensure the pipes have similar static pressure and large diameter to sustain any changes in the flow rates.

How is the Line Up of the ports and Pipes?

The piping lineup will help you in deciding whether to use the T-port or the L-port. The arrangement is different to serve the various functions, such as diversion or mixing. In a diverter, the center port will be the standard one while in the T-port valve, one of the sides will play as the standard port. You can also utilize the T-port to work as an L-port simply by changing the arrangement.

Things to Note When Choosing a 3-Way Valve

- The arrow symbol on the handle indicates the position of the cut-out ball.

- The L-port valves only direct flow through a quarter-turn (90-degrees).

- If you want a proper mix with the T-port valve, you should maintain the consistency of the head of the mixing streams.

- You can use a T-port to direct flow in any direction but can only partially shut off the valve.

- Make servicing effortless by incorporating flanges on every port. Flanges will make your work easier, especially during operations.

2 Way vs 3 Way Valve

Many people new to industrial valves may face the challenge of deciding which valve is best suited for their industrial application. The 2-way and 3-way valves are both useful valves but they both serve different purposes. The two valves have the same elements but the clear difference between the 2 way and the 3-way valves is the number of openings. The two valves can be operated by electric actuators or pneumatic ones. However, there are some features that differentiate the two valves. Below is an overview of the main differences.

Application

The 3-way valve is used to change the direction of the flow and sometimes to mix different media from the two inlets to one outlet. During the mixing of the different media, the fluids involved are mixed in the valve body and transferred by the outlet port to their destination. When you use the 3-way valve as a mixing valve, the media of different pressures and temperatures from the two ports are mixed inside the valve and directed out through the AB port.

As a diverting valve, the media flows from AB to B or AB to A and vice versa. On the other hand, the 2-way valve is used in pipe systems/closed tubes as shut-offs for media (liquids and gases) moving through it. They are basically found in on/off applications and they are called the isolation valves.

The 2-way are also applicable in emergency situations as they can stop media flow to a particular location immediately.

Features

The two-way valve has two openings, an inlet, and an outlet where the tubing and the valves are connected. The ball in a two-way valve has a single straight opening via which the media passes through. The three-way valve has three openings, an inlet, and two outlets, and vice versa. The openings give it more flexibility to perform more functions.

Finances

2-way valves can be cost-effective since they have the ability to increase efficiency through cooling and heating systems. However, 3-way ball valves are more economical for piping systems since they can be utilized for both diverting and mixing media, instead of having multiple 2-way valves.

Water Flow

You can use a 2-way valve in a system with unpredictable water flow that has changes in pressure, flow, and temperature. You can run cooling and heating systems at different rates, lowering operating costs but increasing efficiency. A 3-way valve is a bit different and it is used in constant water flow systems.

Working Principle

The working mechanisms of the two valves are different due to the number of orifices each valve has and the various functions they each serve. The 3-way valve works by rotating the ball in the valve when you turn the handles. The ball aligns the cut-out channel with the outlets and inlets. For the L-port, the L shape transmits the media through 90 degrees from one opening to the other. For the T-port valve, the T shape also sends fluid from one port to the other, moreover, rotation can also cause alignment between the T shape and the port so that mixing happens.

The 2-way valve has two connections; an inlet, and an outlet. They are called the cavity port and the body orifice port respectively. When there is power in the valve, the plunger opens up permitting fluid to pass through the cavity valve and transmits it out via the outlet. If the valve is de-energized, the orifice closes up and the transmission is halted.

Why are Handles so Important for Three-Way Ball valves?

Handles are a part of the valves and they serve an important purpose in the working of the valves. Why are handles so important? Simple handles are the regulating factor to prevent the valves from exceeding the required angle such as the 90-degree turn. The handle stops are especially essential in three-way valves due to the number of orifices in the valve. The three openings can cause havoc if not well-controlled.

The handle plays the role of regulating the amount of fluid that passes through the valves by diverting or combining it if any mixing is required. The handle also has a regulation system called the handles stops. The handle stops are an extension of the handles and the valve body top. Their function is to control the rotation of the handle by preventing the handles from exceeding their set rotation limit. The limit is usually a 90-degree turn.

Handles are also essential in the three-way valve since they determine the position. The basic valve usually has 2 positions, that is, it is only limited to a quarter turn. It is referred to as a selecting, directional, or diverting valve. The handle rotation determines the position of the valve, the L-pattern valve has additional positions such as the 180, 270, and 360 degree turns.

In the 180-degree limit, it starts with a flow between the left and the bottom port. A quarter-turn clockwise permits flow through the bottom and the right port. An additional 90-degree clockwise turn to make it 180-degree leads to a cut-off of the flow. It is known as the three-position valves; the starting position, quarter-turn, and the 180- turn.

The four-position is simply an additional 90-degree turn from the 180-turn. When the valve is in the 180-degree position, it is completely closed. An additional quarter-turn will still not open it but will lead to a four-position valve (270-degree turn). If you want the flow to reopen, you will need to add another turn to make the rotation a complete 360-degree turn.

Trouble Shooting in 3-Way Ball Valve

In any industry dealing with piping systems, there are some problems that you need to anticipate. Most of these problems are minor and you can easily fix them. However, some of the issues facing valves can interfere with the performance of the valves and the operations at large. Such problems need to be fixed immediately after detection to prevent deterioration of operations and prevent any danger that may result due to the faults. Some of the most common issues facing valves are as follows.

What To do During Leaking

Sometimes issues like leakages can occur in a valve, and the 3-way valve is not exempted. Although our valves are durable and strong to withstand various conditions, leakages can sometimes happen. When it happens, you first need to find the reason behind the leakage to fix it correctly. The most likely cause can be a problem in the seal surrounding the valve. The solution is to remove the seal and replace them with new ones.

Another issue can be a crack on the ball valve where the pipes connect. It can be due to corrosion or old age. You can replace the valve with a more suitable one that is durable and rust-resistant. A quick hack as you wait for the replacement, put tape on the edges to act as a temporary seal.

How to Solve a Blockage

A blockage is a common problem in any piping system. The media flowing through the pipes can deposit debris on the valves and will accumulate over time. The debris build-up will cause interference in the flow of the concerned fluid. Although it can be a huge problem for piping systems the 3-way valve has been carefully designed to handle such a problem. You can effortlessly remove the valve from the pipe and clean it. Cleaning and reinstalling the valve is straightforward.

Solving a Jam in the Valves

Jamming occurs when there is corrosion or minimal usage of the valves. You can easily solve this problem by cleaning the valve and ensuring regular use. If it is corrosion, apply a suitable lubricant but if it’s much, replace the part entirely. Get a suitable valve that is corrosion-resistant from a reliable industrial valve manufacturer.

Failure to the Actuator

Actuators are elements that facilitate the movement of the valves in terms of opening and closing. Failing of the actuator will result in disruption of the system since the valves will not open or close as required. The problem may be due to electric or motor failure. Solving this issue will require professional help. Fixing the actuator repeatedly may become expensive, hence the more economical solution is to replace the actuator.

Chattering

Valve chattering is an unpleasant noise found in the valve body. The possible cause is vibration from the plug or the spindle. The vibrations can cause destructions to the valve parts, reduce the efficiency of the valves, and cause failure in the system after a while. If you ignore this problem, it will cost you a lot of money to repair the valve.

The vibration is caused by either wrong part orientation or sizing. Due to the improper features, the flow and spring pressures in the system lead to the chattering noise you hear in the valves.

Water Hammering

Hammering is also a common problem in valves. Hammering is a pressure overload resulting when gas and liquid are forced to alter the direction or stop suddenly. It occurs when you suddenly close the valve at the end of the pipe. The resulting problem is vibrations and noise, which later lead to the destruction of the piping system. This problem will require repair and maintenance which causes money.

You can prevent water hammering by using a faster-closing valve that prevents the pressures from surging. It also prevents shock waves that damage the equipment.

Conclusion

The three-way valve has proven to be among the most useful valves in piping systems. The many functions of the valve from diversions, mixing, shutoffs, and many more make it a huge part of industries. If you need a multipurpose valve that solves all of your problems at an economical price, then you are in the right place. The three-way valve has multiple applications and advantages that surpass all the other valves combined. Also, it is an easy valve to deal with as most of the problems it faces are easily solved in a cost-effective way.

Reach out to us for any inquiries you may have about the three-way valve and get a chance to get recommendations from the best valve manufacturer in the world.