Double block and bleed and double isolation and bleed are two very common terms used to describe valves that feature tight sealing and draining capabilities. However, there is still a lot of confusion about what the two terms really mean and how are they different. Part of the reason why these terms are still so ambiguous is that different valve manufacturing companies and industries have their own definition for DBB and DIB valves.

This blog is aimed at eliminating that confusion by providing a clear double block and bleed definition and describing the difference between DBB and DIB valves. Read on to find out more.

Table of Contents

What Do DBB and DIB Really Mean?

There are many different definitions of double block and bleed and double isolation and bleed valves available in the industry. Different valve standardizing authorities have their own versions of what makes a valve have DBB or DIB capabilities. However, the API’s definition of the two valves is the only one that is universally accepted by valve manufacturers and end-users. The American Petroleum Institute (API) is a trade organization that outlines many industry guidelines for safe operations. It acts as an advocate and a researcher for America’s oil and natural gas industry.

API 6D “Specification for Pipeline Valves” standards define double block-and-bleed (DBB) valve as a “single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve, with a means of venting/bleeding the cavity between the seating surfaces.” They also mention that a DBB valve cannot provide positive double isolation if only a single side of the valve is under pressure.

In the case of DIB valves, API defines them as a “single valve with two seating surfaces, each of which, in the closed position, provides a seal against pressure from a single source, with a means of venting/bleeding the cavity between the seating surfaces.” They go on to say that a double block and isolation (DIB) valve can provide positive shutoff when pressure is coming from one direction or both directions.

How is a Double Block and Bleed Valve Different From a Double Isolation and Bleed Valve?

The main difference between DBB and DIB valve is in the way the two valves function. Double block and bleed valves provide a firm seal against pressure from both sides of the valve. However, the pressure needs to come from both ends at the same time for the valve to work. Pressure from any single side will not be successful in sealing the valve completely.

Double isolation valve, on the other hand, provides a seal against pressure from a single side of the valve as well. This additional seal is important in critical applications where leakages and/or contamination have to be prevented at all costs. DIB valves are mostly used in high-pressure, high-temperature critical operations in industries like water, gas, and oil. They are quite popular in the food and beverage, pharmaceutical, and cosmetic industry as they provide a firm defense against contamination of medium.

Another difference between the two valves is how they relieve pressure. DBB valves usually feature two self-relieving seats that are unidirectional. These seats are capable of releasing any extra pressure on the valve without the need for an external mechanism. Double block and bleed philosophy is different. Since these valves provide a seal against pressure from both sides of the valve, they feature one or two bidirectional seats. However, these seats are not self-relieving. This means a DIB valve cannot relieve extra pressure from the body cavity unless it is helped by an external mechanism.

How Does a Double Block and Bleed Valve Work?

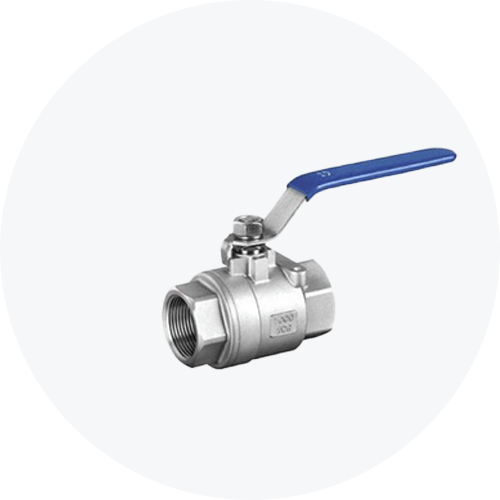

Double ball and bleed valves feature a single valve unit that houses three different valves. Two valves are used to control the flow of medium and a third valve is used to bleed any access medium from the valve body. Here is what a typical double block and bleed ball valve looks like.

The valves in a DBB valve are attached as either a unit or a manifold inside one compact body. The block valves are installed on either end while the bleed valve is in the middle. The DBB valve works by isolating the onstream flow of fluid or gas from either end of a pipeline. It then uses the bleed valve to drain the excess medium.

For example, if you want to remove impurities from a certain medium that is flowing through a critical process unit, you have to isolate one area of the pipeline from the rest of the system. To do this, you have to install a DBB valve like the SIO Double Block and Bleed Ball Valve between the pipeline and the machinery. This DBB ball valve will house two ball block valves and one ball bleed valve. One ball block valve will isolate the upstream of medium while the other will shut-off the downstream. When both ball block valves are tightly sealed the flow of medium to and from the machinery will stop. You can then open the side of DBB valve that is connected to the machinery to drain the contaminated medium. Once it is drained, you can seal the bleed valve shut.

What Kinds of Valves are Used in Double Block and Bleed Valves?

Almost all kinds of valves can have DBB capabilities. Trunnion mounted ball valves can handle high-pressure operations and provide better bi-directional shut-off. A needle valve can be used as the bleed valve as it can cut through the slurry and corrosive mediums.

Gate and globe valves can be used as block valves effectively as they are easy to operate and can be used in many different applications. Expanding plug and expanding gate valves can be used to block the flow while a needle valve or ball valve bleeds the surplus medium. The type of DBB valve you use depends on the nature of the medium, its pressure and temperature, and many other factors. For example, corrosive medium may require stainless steel DBB and DIB valves that can manage the flow of medium without getting damaged. Low-pressure operations may only require a single DBB or DIB gate valve with flexible wedges and a body bleed valve.

What are the Applications of DBB and DIB?

DBB and DIB valves are often used interchangeably in many industries. They are both used to provide isolation in critical applications. They also prevent product contamination and maintain system integrity. DIB and DBB valves are used for many different applications across different industries. They help check the integrity of seat seals in different industries like LNG, petrochemical, chemical, water and gas, and more. They are also used for isolation in the transmission and storage industry, refined products transmission lines, natural gas industrial processes, and mainline and manifold valves in liquid pipelines.

DIB valves are specially used in isolating critical operations where the liquid flowing upstream and downstream must not leak or be mixed with each other. For example, in liquid service near waterways or municipalities, DIB valves can provide a tight mechanical seal both upstream and downstream at the same time, while providing an additional seal from pressure from any one side.

Source: http://www.wermac.org

DBB and DIB valves are also used in the meter calibration market to ensure correct calibration in every operation. The valves in a meter system must seal tightly as even a small leak can cause errors in the meter calibration. This can make the end-users lose a lot of time and money. Choosing the right API-6D DBB or DIB valve can help get the correct calibration almost every time.

Both DBB and DIB valves are used for repairing, replacing, or maintaining the machinery without disturbing the unit. In high-pressure, high-temperature applications, DBB and DIB valves can be used to isolate the area that needs repairs. This is done by depressurizing the specific area that requires isolation. DBB and DIB valves’ reliable tight sealing ensures complete and reliable isolation of critical applications.

Conclusion

Both double block and bleed valves and double isolation and bleed valves are used extensively in different industries. This is because they provide the functionality of three different valves in one compact package. These valves are light in weight and don’t require any supporting brackets so they are easy to install. They are anti-static and feature anti-blowout stems making them resistant to system vibrations and changes in pressure. DBB and DIB valves are great for ensuring tight sealing and maintaining system reliability and integrity.

Looking for a high-quality DBB or DIB valve, browse our catalog of industrial valves to find the right fit. Not sure which valve is perfect for your needs, get in touch with us and our experts will help guide you to the right product.