Valves are an important component of any kind of piping system. They help start, stop, and regulate the flow of materials and prevent leaks and unwanted flow. Valves are vital to the operations of many machinery and equipment across various industries and applications. It is hard to imagine a set-up where valves are not involved. However, not all valves are the same.

While there are many different types of valves available in the market like 220v solenoid valve and globe valve, ball valves and gate valves are two of the most common types of valves used in almost all industries. Though both of these valves perform more or less the same function, there are structural differences between the two that make them suitable for different applications. It can be confusing to choose which one is suitable for your needs. That is where this guide can help you. Read on to find out how gate and ball valves work, what makes them different from each other, and how you can choose which one is best for your application.

Related Products

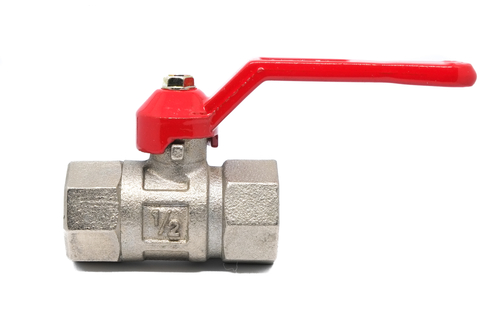

What are Ball Valves?

Ball valves are ‘shut-off valves’ in that they help prevent the flow of materials through the piping system. They are called ball valves because of their structure and function; each valve features a small sphere or ball inside. The ball has a hole in its center called a bore, it is the position of this bore that indicates whether a ball valve is open or closed.

Ball valves are normally controlled by a lever. This lever can rotate 90 degrees, when it is rotated perpendicular to the pipe, the ball valve is opened. The bore of the valve aligns with the pipe and allows materials to flow through. Rotate the lever again bringing it parallel to the pipe to stop the flow. The bore of the valve now becomes perpendicular to the pipe and stops any flow.

Ball valves such as air operated ball valve have a simple design and are easy to turn on and off quickly. They are durable, rarely freeze, provide reliable service, and can be used across multiple industries and applications. They are mostly used in oil and gas applications, marine applications, pharmaceuticals, and more. Ball valves are compact in size and require very little space to install.

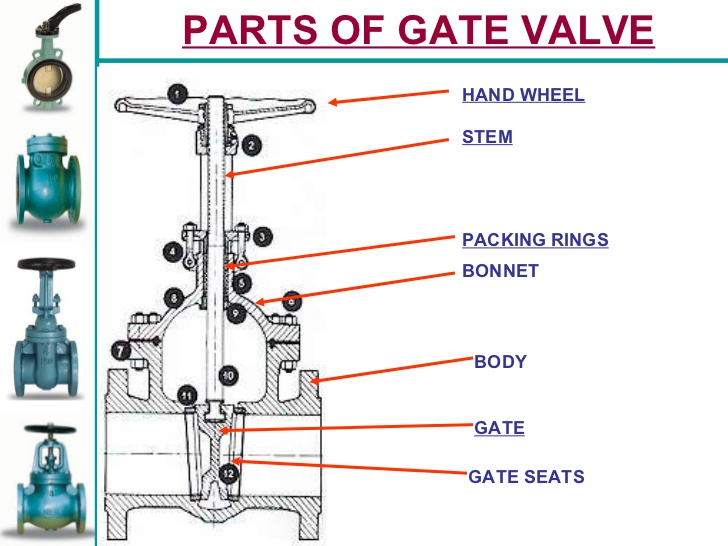

What are Gate Valves?

Gate valves get their name because they feature a flat closure element that moves up and down to start or stop the flow of materials. This closure element, also called a gate, is connected to the stem of the valve. The stem is in turn connected to the actuator, which in case of manual gate valves, is a handwheel. When you rotate the handwheel, the gate slides up, removing any barrier for the materials in the pipe and they are free to flow. Rotating the handwheel counter clockwise, slides the gate back in place, stopping the flow of materials.

Cast steel gate valve are sturdy and durable. They are used in on/off applications where the valve is used infrequently. You can find gate valves in the oil and gas industry, pharmaceuticals, manufacturing, automobile industry, and marine applications. Gate valves prevent pressure drop due to flow of materials. That is why they are great for high pressure and high temperature applications as well.

Gate valves come in many different shapes and sizes. They are extremely versatile both in terms of design and application. They are bi-directional which means you can use them to regulate flow of materials in any direction. They also require very little maintenance and can last for ages.

What are the Differences Between Ball Valves and Gate Valves?

Now that you know what ball and gate valves are and how they work, let’s take a look at what makes them different from each other. As both valves perform basically the same function, it can be confusing to choose which one is right for your needs. Here are some main differences between ball valves and gate valves.

Structure

Ball and gate valves may work in similar ways, but they have different structures. While ball valves feature a small sphere attached to a stem, gate valves have a round or rectangular gate that is attached to the stem and is used to regulate the flow of materials. Because of the way they are structured, ball valves offer immediate shut-off, which is not possible for a gate valve to do.

Source: https://www.slideshare.net/aks_shriv/valves-8662201

Gate valves don’t provide quick shut-off, but they do give you more finely tuned control over the flow of materials and the pressure of the flow. For example, gate valves are great in situations where there’s high water pressure potential. In similar situations, a ball valve would likely form a water hammer, while a gate valve makes sure that doesn’t happen.

Ball valves may in smaller is size than gate valves, but they require more space for actuation. Manually operated ball valves require their lever to be turned at 90 degrees to work. The lever requires more space to work. While a manual gate valve is operated through a handwheel. So even if the gate valve is larger in size, it may take less space than a ball valve to operate.

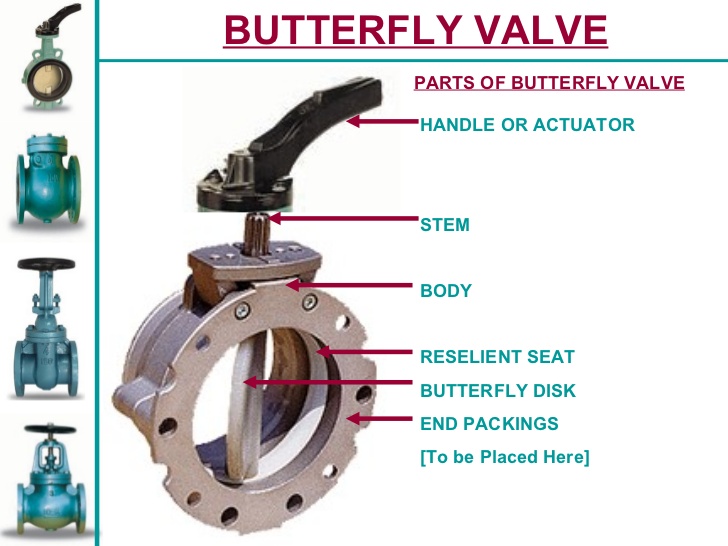

Source: https://www.slideshare.net/aks_shriv/valves-8662201

Another structural consideration is that gate valves are more prone to corrosion than ball valves. The valve opens and closes with a screw handle attached to the gate. The handle is in constant contact with the material flowing through the valve and can easily corrode. This hampers the performance of the valve. You can choose a material like stainless steel and brass for handle construction to counter this problem.

Ports

The inlets and outlets of a valve are called ports. Gate valves are bi-directional, this means they have only two ports. The ports can be threaded, soldered, or flanged depending upon the type of gate valve and the application.

Ball valves on the other hand, can have two or more ports. These ports may be threaded, soldered, or flanged based on the valve’s application and type. Ball valves with three ports are used for mixing and diverting the flow of materials. In addition to their number, the size and function of ports in valves also plays a role. A full-port ball valves features a ball with a bore size that is the same as the diameter of the pipeline the valve is attached to. A reduced-port ball valve features a ball that has a smaller bore size than that of the pipeline.

Flow Characteristics

Gate valves can function in either fully open or fully closed states. If a gate valve is partially open, it causes throttling which can damage the valve and affect its function. Also, a partially opened gate valve is not proportional to the motion of the closure element. This means you cannot use gate valves for active control of media flows. Gate valves are more suitable for shutoff of materials flowing in linear direction. They are used in piping situations where flow needs to be regulated infrequently like when isolating equipment or sections of pipes.

Ball valves are designed so that the flow of materials is closely proportional to the rotation of the closure element or ball. This causes a flow characteristic called the ‘modified equal percentage’. Ball valves are thus suitable for active control of media flows. Ball valves seal very well, better than gate valves in most instances. That is why they are great for regulating the flow of gasses and other light materials that are prone to leakages. Ball valves have a quick shut-off so they are mostly used in applications where you need to start or stop the flow completely and frequently.

Actuation

Gate valves are usually used for isolation of general purpose flows and for high-pressure and high temperature applications that require manual operation. This is the reason why most gate valves are actuated using a handwheel. The handwheel offers more control over opening and closing the valve. However, it is more difficult to operate as it requires great strength especially during high-pressure operations. Also, since handwheels need to be rotated for the valve to turn on or off, it is difficult to actually ‘see’ whether the valve is open or closed. This problem is eliminated when using mechanical, electric, or pneumatic gate valves.

Ball valves are used for active control of material flow so they can be manually, electrically, or pneumatically actuated. Manual ball valves are more frequently used in industries as they are cheaper and they offer greater control over the flow of materials. Another advantage of manual ball valves is that the lever needs to be held perpendicular to the pipeline for the valve to be opened and turned back when closed. This makes it easy to ‘see’ just from the position of the lever whether the valve is open or closed.

Cost

Comparing the cost of gate and ball valves is like comparing apples and oranges, since both of them are used for different purposes and applications. However, if all things are kept the same, ball valves are generally more expensive than gate valves. This is because they offer more features and are more versatile than gate valves. Also, metal seat ball valves and carbon steel ball valve are more durable than gate valves as they are less prone to corrosion. So the slight increase in price more than makes up for the years of use you’ll get out of ball valves.

How to Choose the Right Valve for Your Application?

Choosing between a ball valve and gate valve comes down to a number of factors. Here are some considerations you need to make to see which valve is better for your application:

- The type of medium that you need to control can dictate the type of valve you need. Gate valves are better with liquids and viscous liquids like oils as they are more prone to leakages than ball valves. Knife gate valves can help you regulate the flow of slurry materials. Ball valves can be used with liquids and gasses like wastewater treatment as they provide a firmer seal.

- The size of the space you have can also help you decide between a ball and gate valve. Ball valves are smaller in size but manually actuated ball valves need more space. Gate valves are normally larger in size.

- The kind of application you require is also important when choosing a valve. Gate valves are more suitable for high-pressure, high-temperature, infrequent applications. Whereas, ball valves like ball valve flange type are more suitable for active control of media flow.

- The cost of valves is another consideration. Ball valves are generally more expensive than gate valves but they offer a more reliable operation as well.

What are Ball Valves Used for?

A ball valve is a shut-off device that permits, obstructs, and monitors the flow of liquids, vapours, and gases in a piping system by rotating the ball with a bore. People often wonder if ball valves are more suitable for plumbing or industrial applications. But it is perfect for both as it comes in various designs and features to satisfy industrial needs.

Depending on the industry where the valve is employed, its standards and specifications alter according to the requirements. Whether plumbing or industrial, a ball valve can be used wherever it comes in multiple styles to serve various purposes, they are smaller and lighter than other valve styles and usually have a low price point.

Industrial Applications

Ball valves are used in different industries for varied purposes. Such industries include oil and gas, pharmaceutical, chemical, HVAC, food processing, sanitary, and others such as corrosive media and cryogenics. Several manufacturing industries also widely employ them as they can effectively function with a full range of media, including liquids, gases, chemicals, potable water, fuels, food, and beverages.

In industries, it controls the flow and pressure in gas distribution systems and reduces the pressure connections with gas storage. They act as a helping mechanism in the food and oil processing industries. Ball valves are widely found in flowing systems on ships, chlorine-making industries, and fire-safe protection services as they are leak-proof, low maintenance, and easy to operate.

Plumbing Applications

A ball valve is ideal for various plumbing applications as it regulates water flow by rotating the sphere with a hole. In the open state, the hole is in line with the pipe, allowing the water to flow through it. But in the closed state, the hole is perpendicular to the pipe to restrict the flow.

In plumbing applications, it offers excellent sealing, but unfortunately, it does not permit precise flow control because it has positive stops.

Using a ball valve in slurry applications is unreliable because the suspended particles can get trapped in the cavities, causing premature leaks, wear, and failure, necessitating replacement. In simple words, ball valves are suited for shut-off service applications. However, some designs, such as V-ported, offer flow regulation.

Ball valves offer several advantages, especially in residential settings. The most crucial are their ease of use, ability to open and close quickly, and availability in multi-port designs.

What are Gate Valves Used for? – Plumbing or Industrial?

A gate valve is a shut-off valve generally used to completely close or permit the fluid flow in the pipeline. It is one of the most common valves used in plumbing, industrial, and water supply systems. It represents a linear-motion isolation valve having a function to start or stop fluid flow.

Since this valve has a closure element sliding into the flow stream to provide shut-off, acting like a gate, it is known as a gate valve. It is perfect for isolating specific areas of the water supply network while carrying out maintenance, repairs, new installations, and even rerouting the water flow throughout the industrial pipelines.

Plumbing Applications

Gate valves are commonly used in plumbing applications to control the fluid flow by raising and lowering the internal gate. It is accomplished using a twist-type handle or knob at the top. But they should not be used to control the volume of media flow as they are designed to fully open or close. Using them to adjust the fluid flow may wear them out.

These valves are perfect for closing the water supply and are widely used as shut-off devices on the main and branch water supply lines. However, since their internal metal parts may rust, it is not uncommon for them to get stuck in on or off position, thus requiring professional help. A gate valve is typically employed in applications where the water needs to shut off infrequently.

Industrial Applications

Gate valves are employed in various industrial applications, including oil and gas, manufacturing, pharmaceutical, automotive, and marine. The non-rising stem gate valves are popular in ships, underground applications, and places with limited vertical space.

These valves are suitable for industries with a demanding environment, such as high pressure or temperature. They are typically used in power plants, water treatment, mining, fire protection, gas supply, chemical and oil industry, and various offshore applications. According to their requirements, one can handle these valves with a handle, gear, or actuator.

A gate valve can handle all fluids, including water and gas. Since this valve is used with potable water, wastewater, and even neutral fluids, it is widely used in various industries.

Replacing Gate Valve with Ball Valve

Both gate and ball valves are commonly used to control the flow of liquids and gases in piping systems. Although both are typically used in similar settings, they have a few differences, encouraging people to replace their existing gate valves with ball valves. Modern houses are built so that if something goes wrong with the device, levers are there to prevent damage.

A ball valve is better suited for lower flow rates, applications requiring more than two ports, and superior durability and sealing. On the other hand, a gate valve is better suited for higher flow rates and applications having small installation space. It is typically more affordable than ball valves. It is ideal for applications involving slurries, large flow rates, and shut-off purposes.

Contrastingly, ball valves are employed in fire protection systems and marine applications. They are not suitable for use in the food, beverage, and pharmaceutical industry as they are difficult to clean and carry the risk of spreading contamination.

Since ball valves are becoming more popular than gate valves in plumbing systems, people choose to replace them. A ball valve is much superior to a gate valve. So, whenever the opportunity comes to install a valve, it is better to go for a ball valve than a gate valve.

If a plumbing system already has a gate valve installed, replacing it with a ball valve is better. Here are a few simple steps to carry out the replacement procedure easily.

- Use a torch to heat all the valve parts to remove them.

- Shut off the water flow and drain the remaining from the valve and the pipe.

- Now heat the area where the valve connects with the pipeline system.

- Grab the gate valve using large channel locks to determine if it is moving.

- If it moves, it is hot enough to remove and easier to cut the pipe to pull out the valve. But if it fails to move, heat a nearby elbow and give it some lateral movement to simplify the following procedure.

- Now clean, flux, and heat the joint to solder them before reinstalling with a ball valve.

If the pipe is cut, use a repair coupling and solder it like the valve. Always keep the valve open when heating it for easy removal. Both gate and ball valves serve a purpose, but the user must pick the right one according to the application.

Gate Valve vs. Ball Valve for Main Line Shut-off

Every household has two types of shut-off valves in their plumbing system, performing entirely different functions. The two most common residential shut-off valves are gate and ball valves. People typically consider ball valves much more reliable than gate valves for several reasons. But the most critical of them all is reliability during an emergency.

But before determining which valve is more suitable for a particular application, it is essential to learn more about its functions.

Gate Valve

A gate valve is an older ‘twist style’ device comprising a round and an oval handle that is rotated multiple times to open or close the gate. It helps in stopping the flow of water in the system.

The gate raises and lowers when the media flows through the pipe to open or close the flow. Its handle sits on a threaded stem screwing in and out as the gate raises and lowers. At the end of the gate, there is a washer to seal off the flow of media when the gate is in the fully closed position.

Ball Valve

A ball valve that is easy to identify due to its level handle must turn 90 degrees to fully open or close the valve body. It features a lever attached to a stainless-steel ball inside the valve. The ball has a hole drilled through it so that when it is on, the media passes through the hole. And when the lever is at 90 degrees, the ball turns to the solid side to shut off the flow.

Although both valves serve almost identical purposes, their choice depends on the application. For main line shut-off purposes, a ball valve is more reliable than a gate valve as the washers in the gate valve eventually wear out, and the stem becomes brittle. It creates many issues in the long run because when the washer wears out, the flow is no longer shut off, thus deeming the device ineffective.

In several cases, when the gate closes, the brittle stem may snap or break, making the valve stuck in the same position until professional services are available. But one must remember that gate valves are unreliable, especially in emergencies. So consider converting all the valves in a home to ball-style shut-off.

It is easy to identify the difference between the two valves by looking at the handle. While a gate valve involves twisting, a ball valve comprises a 90 degrees lever.

Stop Valve vs. Ball Valve

Every plumbing system requires a top-quality valve to keep all the lines secure and free from leaks for many years. Although several types of valves are available in the market today, the most common are ball and gate valves, also known as stop valves.

Identifying the difference between these two just by looking at the lever is essential as it helps identify which one is more suitable for a certain application. Besides, everyone knows that water eventually wreaks havoc on every aspect of a plumbing system. But employing the right kind of valve can help delay the problems.

Although stop valves have been around for ages, they are slowly becoming obsolete. Today, the most common types of valves used for shut-off purposes are ball valves. The design of ball valves is much superior to gate valves. It is proven to last longer, causing fewer problems down the r.

A ball valve features a sphere with a drilled hole to control the media flow. When the handle is turned parallel to the device, media flows through it. But when it turns 1/4th, the sphere also turns, and the hole becomes perpendicular to the valve, stopping the media flow. The best thing about a ball valve is it is good for use even after years, as it does not typically get stuck in a position.

A stop valve features an internal gate moving up and down on a stem that connects to a handle. It screws the gate up and down, thus opening and closing the gate. However, it has a few disadvantages. One of them is over time, the stem controlling the gate may break. It causes the gate to get stuck in a particular position, making the media either stuck on or off.

Another issue with a stop valve is them being notorious for seizing shut after a long period of no use. Even if the valve free ups, it usually starts to leak. Although a stop valve is not recommended, some areas require using these valves before and after the water meter. The reason is a ball valve’s inability to shut off quickly with just a quarter turn.

Besides, even if a ball valve can shut off quickly, it usually causes water hammer conditions and other problems in its body.

To sum up, even though both valves are designed to restrict or control the media flow, using the appropriate one is essential to prevent leaks and longevity.

Conclusion

Both ball and gate valves are used frequently in many different kinds of industries and across different applications, which include the chemical industry, diesel shut off industry, water shut off, and slurry applications. Choosing the right valve for your needs can be easy when you break down the operation you need the valve to perform. No matter which valve you choose, make sure to buy from a trusted valve manufacturer and get valves that have proper warranties. At SIO, one of the best high pressure ball valves manufacturers, we offer a great deal of attention to design, manufacture, pack, and deliver valves that are of the highest quality. We use state-of-the-art testing equipment and software to make sure our valves are safe to use and provide reliable operation for years. If you want to know some info about how does ball valve work, ball valve types or 3 piece vs 2 piece ball valves, you could subscribe our website, SIO will continuously output of new content.

Learn more about our products here. Browse through our catalogue to find the best gate valves and ball valves for your needs.