Ball valves and butterfly valves are the two most common valves found in any piping unit. They are frequently used to manage the flow of medium through pipes. This is the reason why they fall under the category of control valves. No industrial unit is complete without one or more of these valves installed in key places around the system.

Since ball and butterfly valves take center stage in any factory or industrial unit, there is often a debate on which one is better and for what application. Time, money, and area constraints can push users to ask the question of which valve will better suit their needs. This blog is aimed at clearing that exact confusion. We will start by discussing the basic definition of ball and butterfly valves and then move on to their similarities and differences. Hopefully, by the end of this blog, you will be able to make an educated buying decision.

Table of Contents

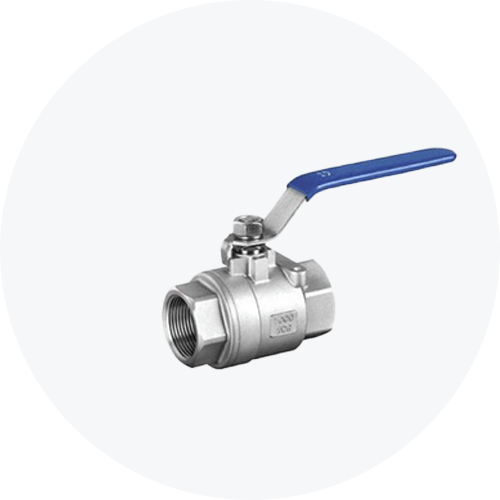

What are Ball Valves?

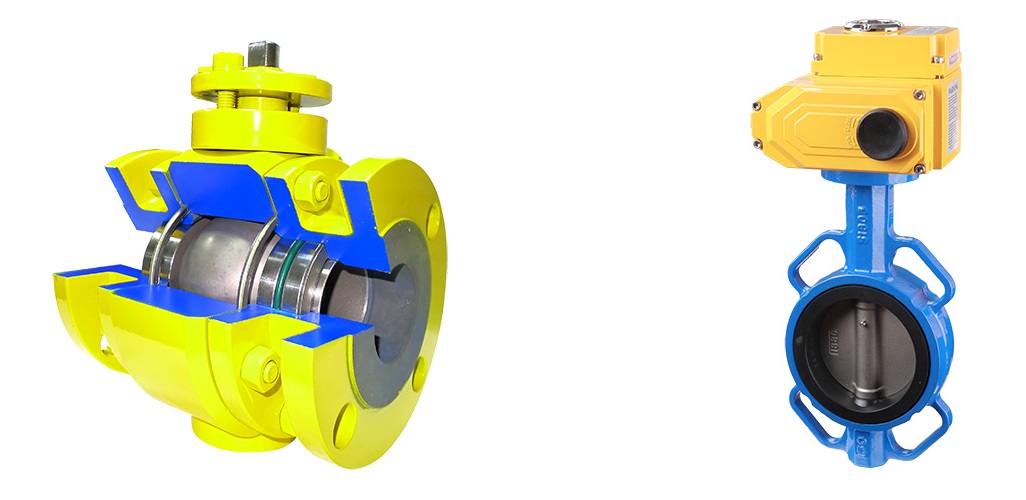

Ball valves and butterfly valves are quarter-turn valves that are used to start, stop, and sometimes regulate the flow of medium through any piping system. Ball valves use a hollow, perforated, and pivoting ball to control the flow of materials from one opening to the next. The valve can be open, closed, or partially open to allow gasses, liquids, and slurries to pass through it. Ball valves are used in applications where tight shut-off is required. This is what a typical ball valve looks like.

Source: https://www.sciencedirect.com

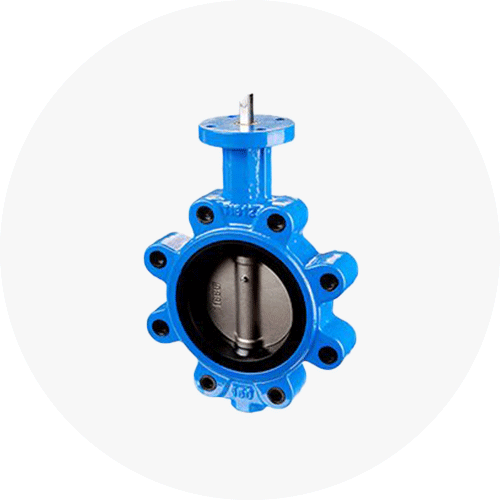

What are Butterfly Valves?

Butterfly valves feature a spherical disk with a hole. The hole has a rod running through it that controls the movement of the valve. As the rod moves, it rotates the disk to open or close the butterfly valve. These valves were originally used in applications where tight closure was not necessary. But modern butterfly valves come with fairly tight seals made of rubber or elastomeric materials providing tight shut-off just like other valves. Here is an image of a butterfly valve.

How are Ball and Butterfly Valves Similar?

Though there are many differences between the two, ball and butterfly valves also have a number of similarities. They are often confused with each other because they are capable of performing similar functions. Here are some other similarities between the two valves:

- Both ball and butterfly valves are quarter-turn valves that require a 90-degree turn to open and close

- Ball and butterfly valves can be made of cast iron, stainless steel, brass, or any combination of these metals

- Both valves can manage the flow of most types of liquids and gasses at a wide range of pressures and temperatures

- Ball and butterfly valves are relatively affordable, durable, and dependable

- Both are widely available in the market in different types and configurations

What are the Differences Between Ball Valves and Butterfly Valves?

There may be similarities between ball and butterfly valves but ultimately they are different in many ways. Here is a look at all the differences between ball and butterfly valves:

Construction

Though both ball and butterfly valves are control valves, they are constructed differently. Ball valves feature a ball as a disk. This ball has a hollow center called a bore. The ball is attached to the stem on one end and sits between two seats on either side. Ball valves provide a tight seal when closed in different kinds of applications. They are also available in a number of different configurations like carbon steel ball valves or air operated ball valves and are customizable to suit your specific needs.

Butterfly valves get their name from their inner structure that looks like a butterfly with its wings open. The body of the valve features a rotating disk with a stem passing through its center. The stem looks like the body of a butterfly with one half of the disk on each side looking like its wings. The stem is connected to an actuator or a manual lever that is used to open and close the valve. Butterfly valves provide a reasonably tight seal in low-pressure applications. As one of the high performance butterfly valve manufacturers, different types and configurations like metal seat butterfly valves are available and can be reinforced to have better sealing abilities in SIO.

Working Principle

How a ball valve works

Both ball valves and butterfly valves are used to control the flow of medium through any piping unit. However, the mechanism for starting or stopping the flow in either is different. In ball valves, as the actuator turns the stem, the bored side of the ball aligns with the pipeline and the medium is allowed to flow freely. Full-bore ball valves allow unobstructed flow of the medium, hence there are no pressure drops. As the actuator is turned again, the stem moves so that the solid side of the ball becomes parallel to the pipeline stopping the flow. Ball valves provide a tighter seal than butterfly valves.

How do butterfly valves work?

Butterfly valves are open when a turn of the actuator rotates the stem which in turn causes the disk to rotate. When the disk is parallel to the flow the medium is free to pass through. When the disk is perpendicular to the flow, the valve is closed and the medium cannot pass through. Unlike ball valves, butterfly valves can also be partially opened or closed to throttle or regulate the flow of the medium. As the disk of the valve is always in contact with the medium, butterfly valves cause a pressure drop in the flow.

Types

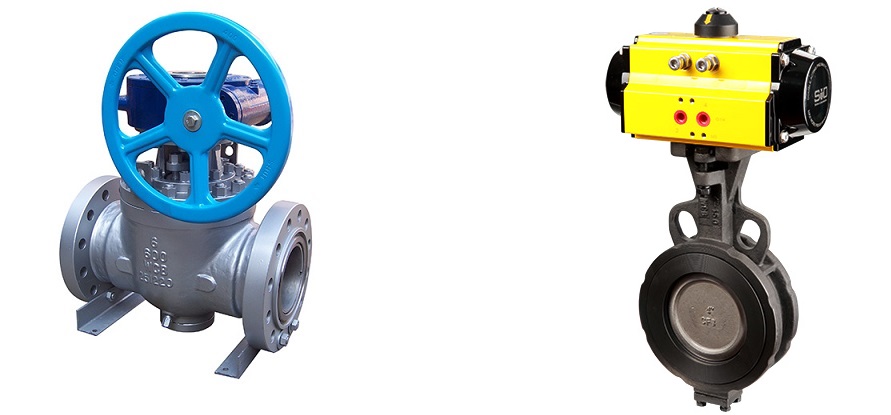

There are many different kinds of ball valves available in the market. They are highly customizable so you can find specialized ball valves like ball valve flange type or SIO Double Block and Bleed Trunnion Mounted Ball Valve as well. Ball valves can have full bores or reduced bore. They can be top-entry, side-entry, or have a split body. Floating ball valves feature a ball that is free to float inside the body of the valve. They are used in applications where a bi-directional shut-off is required. Trunnion mounted ball valves are suitable for high-pressure, high-temperature operations.

.jpg)

Butterfly valves can be concentric or eccentric, and it has different actuated methods like a pneumatic butterfly valve or air actuated butterfly valve. Concentric butterfly valves or resilient seated butterfly valves have a stem that is centered in the middle of the valve disk, which in turn is centered in the pipe bore. Eccentric butterfly valves can be double offset or triple offset depending upon the stem and disk structure. Eccentric valves are able to manage high-pressure operations more effectively. Based on structure, the butterfly can be wafer style for bi-directional shut-off or lug style for dead-end services.

Applications

What are ball valves used for

Even though both ball valves and butterfly valves are used to manage the flow of different kinds of the medium through a unit, they are used for different applications. Ball valves can provide a tight shut-off for liquids, gasses, and slurries. Since the ball is not in constant contact with the medium, there is no pressure drop making the metal seat ball valve perfect for high-pressure operations. SIO Ball Valves are used in many industries including turbine, compressor, separator, and generator skids, gas feed lines, crude oil plants, polymer plants, LNG plants, field gas and industrial gas processing plants, tank farms, petroleum refining, oil refinery feedstock lines, desalination, hydrocarbon processing, brewing, and automated process applications.

What is a butterfly valve used for

Butterfly valves can provide shut-offs for liquids and semi-liquids. Butterfly valve is an essential piece of equipment for flow control. They cannot be used effectively to manage gas applications as they don’t provide a tight enough seal. Butterfly valves are suitable for low-pressure applications as they create a pressure drop in the medium. If used in high-pressure applications, butterfly valves need an external pressure balancing scheme to work effectively. Since butterfly valves are lighter than ball valves, they are more frequently used to manage large scale operations. Lug style butterfly valves are used to cordon off areas of the pipeline for maintenance. They are frequently used in chemical, agricultural, and water and wastewater treatment services in addition to fire protection, pharmaceuticals, and food industry.

Limitations

Ball valves are heavier in weight and larger in size than butterfly valves. They are usually difficult to install in tight spaces. However, it is also difficult to use ball valves in really large applications as large-size ball valves are expensive to manufacture, not to mention really heavy. Ball valves cannot be used for throttling purposes, they are either fully open or fully closed.

Butterfly valves are rarely used in high-pressure situations as they cause a pressure drop. Another reason is that high-pressure may make it really difficult to open and close the valve. Butterfly valves cannot be used with gasses and slurries as gasses can easily leak through while slurries will get stuck in the body of the valve. It is hard to clean and maintain a butterfly valve as the internal parts are not easily accessible. Butterfly valves are generally a little more expensive than ball valves.

Conclusion

Ball valves and butterfly valves are an important part of any industrial piping unit. The type of valve you choose for your application depends on the nature of the medium, working conditions, size of the pipeline, and more. Information about ball valve vs gate valve could also click here. If you want expert advice on which valve will be right for your needs, feel free to get in touch with us. As one of the best high pressure ball valves manufacturers, our team of experts will not only guide you to the right products but also help you increase the efficiency of your operation.