The 3-way ball valve is one example of a multiport ball valve that offers a variety of options for process control applications and are widely used by industrial valve manufacturers. When dealing with many media, these valves provide greater versatility. However, for someone who has never used one before, multiport valves can be a little complicated. Make sure you understand what a common ball valve is before learning about 3-way ball valves. This article will help you understand what 3-way ball valves are and how does a 3 way ball valve work.

What Is a 3-Way Ball Valve?

Suppliers of ball valves must create ball valve designs that can handle different operations without requiring the installation of additional valves. Multiport ball valves were created as a result. Three apertures on a three-way valve can simultaneously function as inlets and outlets. This valve’s key benefit is its cost-effectiveness because it can function as both a control and a shut-off valve.

Because they are a simple and affordable technique to manage both shutdown and flow channels in a single valve body, 3-way ball valves are widely used. A three-way valve’s ability to control flow is accomplished by altering the way the pipe is arranged, how the valve ball turns the handle, and how the valve ball flows through the ball.

With the proper valve type and configuration, a 3-way ball valve can be used in a variety of ways to service or control the flow based on the needs of various processes. The following are some objectives that a 3-way ball valve can meet:

- Put a full stop to the flow.

- Combine two distinct liquids from several sources.

- From one location to another, flow can be changed.

- There are two alternative destinations where flow can be routed from one input.

- It can prevent flow in one direction while allowing it in another.

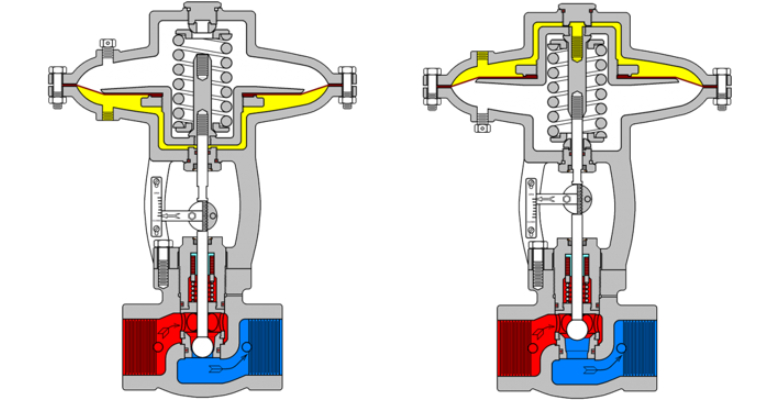

What a three-way ball valve will perform is determined by a single, crucial internal design distinction. The flow pattern or contour of the port through the ball within the valve is this important design distinction. The majority of three-way ball valves contain valve balls with flow patterns resembling either a capital L with two flow channels or a capital T with three flow paths.

What Types of 3-Way Ball Valves Are There?

L-Port and T-Port are the two different types of 3-way ball valves. An L-Port has the ability to entirely stop flow as well as send it in either direction. While a T-Port cannot be turned off, it will carry out all the same flow functions as an L-Port. The T-Port can also combine flows by transmitting or receiving flow to/from the Tee in both directions. The letters “T” and “L” stand for the ball’s opening’s form.

There is also a three-way full port high pressure ball valve that can handle pressures of up to 5800 psi. Numerous process fluids, including hydraulic oils, are compatible with this valve. The valve body of a high pressure 3 way ball valve is offered in stainless steel as well as carbon steel.

3-Way Ball Valve Working Principle

When it comes to three way valves operation, SIO will you “How does a three way valve work” in this part. Since there are two different types of 3-way ball valves, this section goes into great detail about each mechanism. 3 way valves differ somewhat from typical ball valve operation mechanisms. When the handle or actuator of an L-pattern type or diverter valve is turned 90 degrees, the flow can be switched from one port to the other.

Assume that the left port and the bottom port are both open in the first position. The valve can be turned a quarter turn counterclockwise to direct media flow to the right port. The figure above illustrates how blocking the flow of media requires a total rotation of 180 degrees and another quarter turn in the opposite direction. The media’s flow would still be obstructed by a 270-turn. The 3 way valve can, however, flip completely around and return to its initial position.

Two of the three ports essentially open simultaneously. This enables the three way valve to have three flow options and two shut-off settings. Because the media from two intake flows can be blended inside the valve, the T-pattern is also referred to as a mixer valve. It then leaves at the opposite end. In a sense, it is possible to open all three ports simultaneously.

The T-pattern ball valve can also function as a diverter, making it comparable to how the L-pattern does. A quarter turn of the handle completes each of these actions. T-patterns can either restrict the flow to two ports or permit access to all three ports, but they cannot offer a bubble-tight shut-off.

The T-pattern ball valve can split the media so that it flows out in two different directions by acting as a mixer. Similar to a two-way ball valve, the T-design pattern’s enables it to split the flow or just provide a straight-through flow pattern.

The common port of a T-pattern ball valve that is vertically positioned is always open. Turning it a quarter turn is the only way to change the direction of the flow. The media’s flow won’t change if you make a 180-degree turn.

There are locking handles so that the valves can be turned to move them; however, for the 3-way valve, these locks are spaced up to 360 degrees apart. To make up for the amount of ports, this is done. Additionally, the port that serves as the standard entrance point is frequently found at the base of the valve.

Features And Benefits of 3-Way Ball Valve

A three-way ball valve working key attributes are as follows:

- Because there is no friction when it opens and closes, less torque is needed to turn the valve.

- The advantages of time and money savings are added by online valve maintenance.

- It has a wedge-shaped sealing surface where the valve applies pressure from the stem to press the ball against the seal in order to create a positive seal regardless of pipeline differential pressure conditions.

- The sealing surface is always free of dirt, and the valve is thought to be self-cleaning because when it lifts from the seat, fluid washes away all the buildup.

3-way Ball Valve operation’s key benefits are:

- It offers a straightforward construction, a small footprint, a small volume, and is lighter.

- Fluid travelling through the valve experiences little resistance from it.

- The valve’s sealing is effective, and vacuum systems use it as well.

- Simple and efficient maintenance is available.

- Its availability in a variety of sizes broadens the range of uses for which it may be put to use.

3-Way Ball Valve Selection Guide

When choosing the appropriate valve for your application, you should primarily take into account:

- Selecting the appropriate and equivalent valve seal requires knowledge of the fluid that will be used in the system.

- Identify the system’s pressure rating to see where the valve needs to be installed.

- Learn what temperature the system typically operates at.

- Verify the type of connection to see if the valve can be connected to the piping or not.

- The valve body’s material must be compatible with the currently in use process lines and suitable for the process temperature and pressure.

- Ascertain the valve’s mode of functioning and whether it can be applied to the current system.

3-Way Ball Valve Vs 2-Way Ball Valve

The components of 3-way valves are identical to those of 2-way valves. It differs from the 2-way valve in that it uses an additional port. 3-way valve assemblies can also be controlled by electrical or pneumatic actuators, just as 2-way valves.

These valves can be used to blend fluids from two inlets to one exit or to reroute fluid flow. Fluids from the intake ports of a mixing valve are blended inside the valve body before being transferred by the exit port. A 2-way valve, on the other hand, can only be used for on/off applications and occasionally for variable flow systems when the pressure, temperature, and flow are all changing.

For diverting and mixing activities, 3-way valves are significantly more cost-effective than numerous 2-way valves. 3-way valves may blend fluids from multiple inlets, making them appropriate for heating and cooling a variety of media, including water, oils, and chemicals. The usage of these valves as bypass valves in primary and secondary loop applications is quite common. Similar to 2-way valves, 3-way valves are likewise applicable in the aforementioned industrial industries.

Conclusion

Flow patterns, handle orientation, and the range of 90-degree revolutions the handle can make are used to categorise three-way ball valves. Depending on how the valve ball is drilled and the pipe layout, gas and liquid flow can be switched between, combined, blocked in one direction, or completely stopped.

Multiport valves reduce room by doing away with the requirement for a second tee and a valve. It is easier to select the best three-way valve and prepare for its installation if you are aware of the basic three-way ball valve design options. Contact Siovalve for more information if you want to learn more about these valves and how they might benefit your company.