A double offset butterfly valve is a high-performance butterfly valve and is one of the most popular butterfly valves in the market today. It is widely used in pharmaceutical, water, food processing, and chemical industries because it is suitable not only for low pressure and low-temperature applications but is also best to use in moderate to high temperature and pressure services.

In this post, we will reveal more about double offset butterfly valves – how they are structured, how they work and how they can help you in your industry!

Table of Contents

What is a Double Offset Butterfly Valve?

Butterfly valves stop, start, and regulate the flow with a quarter-turn rotary motion. Their mechanism and structure are parallel to those of ball valves. However, systems that do not need positive shut-off use butterfly valves, instead of ball valves.

One of the most commonly used butterfly valves is the double offset butterfly valves. This type of butterfly valves is a great and affordable alternative for the globe, ball, and gate valves because they are compact and are relatively lightweight.

Double offset butterfly valves have two stems offset from the center. The first offset has the shaft’s axis behind the valve’s centerline, while the second is around the body of the valve or pipe’s centerline.

The shaft is placed from the first offset and the second offset to displace the seat of the valve properly. Doing so produces a cam action during the whole operation of lifting the seat out of the seal, resulting in friction for the initial 10 degrees of opening and final 10 degrees of closing. Thus, the double offset butterfly valve makes the entire process smoothly.

Double offset butterfly valve yields seals at low, medium, and high pressures and it allows up to two inches of pipe insulation.

How Is a Double Offset Butterfly Valve Constructed?

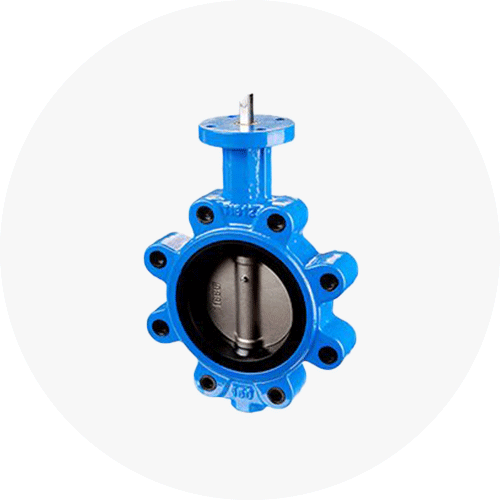

The many different functions and benefits double offset butterfly valves offer are well supported by their designs and components. All butterfly valves, including double offset butterfly valves and pneumatic butterfly valves, have four main components. These are the disk, seat, body, and stem.

Here is a diagram along with other minor parts to help you know and locate where these components are in a butterfly valve:

Source: https://hardhatengineer.com

Disk

This disk is a double offset butterfly valves is responsible for closing the valve to stop the flow. Interestingly, the function of the disk is just similar to a plug for a plug valve, a ball for a ball valve, and a gate for a gate valve. The disk plays a part in the butterfly valve’s role in the flow regulation of chemicals and water, and the control of air in a car’s carburetor.

Over the years, the designs of the disk varied to align with the stem to position the disk properly. It has also been updated to make improvements with the flow, and the sealing or operating torque. By rotating it 90 degrees, the disk can close and open the butterfly valve.

Seat

In double offset butterfly valves, the seat provides the shutoff through a line-energized or interference-fit design. It puts the pressure in the pipeline to increase the interference between the disc and seat edge. The seat can be locked in or bonded to the body.

Usually, the seat is manufactured with polymer materials. But if you need more excellent resistance to higher temperatures, metal seat butterfly valves are often found in high-temp and pressure applications.

Body

A butterfly valve body varies. For double offset butterfly valves, they have a body that will fit in between two pipe flanges. The most common designs are the lug and wafer body designs.

The lug type body provides bolt holes using protruding lugs. The wafer design body, however, does not use protrusions, but instead, it is placed between the pipe flanges to surround the bolt holes.

Each has its own set of advantages and disadvantages. For the wafer type, although it costs less, the weight of the piping system is not transferred directly to the body. The lug type, however, can remove downstream piping, or what they call dead-end service.

Stem

The butterfly valve’s stem can come in a one-piece shaft or a split-design or two-piece shaft. It is in contact with the media, so it should always be compatible. Although they come in separate pieces, the disk needs the stem to be placed in the proper position. The stem provides the strength needed to seat or unseat the disk.

How Does a Double Offset Butterfly Valve Work?

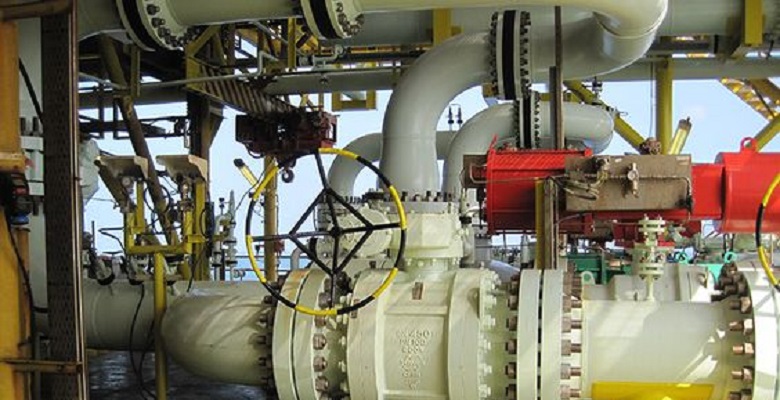

The double offset butterfly valve is ideal for systems that require higher pressure resistance. They are typically used in power generation, water and wastewater treatment, HVAC, and shipbuilding and often found in water, petrochemical, and slurry industries.

By positioning the disk in the center of the pipe bore, it increases its sealing ability and reduces the risk of wear to the valve. If you are looking for a double offset butterfly valve that gives you service for a very long time, SIO High-Performance Butterfly Valves will do the work for you.

To isolate and regulate the flow, the disk of the double offset butterfly valve represents its closing mechanism. Placed in the center of the pipe, the disk, referred to as the butterfly, is mounted on a rod that connects an actuator found outside of the valve.

The rotation of the actuator sets the perpendicular or parallel direction of the disk to the flow. To regulate the flow properly, adjust the level as you keep a close eye to the desired output flow. Compared to a ball valve, the disc of this valve is always present in the flow, which induces a pressure drop no matter what the position of the valve is.

Coming from the family of quarter-turn valves, when the double offset butterfly valve is closed, you have to turn the disk to make that it blocks off the passageway completely. Rotate the disk into a quarter turn to provide an unrestricted passage for fluids or air to pass. You can consider incrementally opening the valve as it leads to throttle flow.

The disk’s movement depends if the valve is open or closed wholly or partially. Partially opening the valve means that the disc will not rotate for a full one-quarter turn, preventing unrestricted passage. Given this, only a small amount of air and fluid will be able to pass through. However, ultimately opening the valve means significant amounts of air or fluid will pass through since the disk will have a 90-degree turn.

Aside from being used with semi-solids, liquids, and gases, double offset butterfly valves serve as control valves in fire protection to shut off or turn the water flow on to the pipes, which serve as standpipe or fire sprinkler systems.

Advantages of Using Double Offset Butterfly Valves

Easy to install and fast to open

Double offset butterfly valves are small, but when they are actuated pneumatically, they are quick to open and close by rotating the handle for 90 degrees. Furthermore, their simple and straightforward design requires a small amount of time to install them.

Affordable costs

Because of their design, butterfly valves do not need a lot of materials. The wafer body design is considered the most practical among all types.

Require less space

Butterfly valves have been designed to look compact, as compared to other types of valves.

Convenient to maintain

One of the reasons why a lot of people choose to use butterfly valves is because they are durable and reliable. These types of valves are not high maintenance because of their simple structure and design like air actuated butterfly valve.

If they are installed properly, their level of wear has been reduced, giving them a longer life to be used. With this, you save a lot of time and money with valve maintenance.

Conclusion

SIO Double Offset Butterfly valves are what you need if you want high quality and durable butterfly valves that can deal with higher temperatures and higher pressure services, because SIO is one of the top high performance butterfly valve manufacturers in China.

If you need high-performance butterfly valves that can manage higher temperatures and higher pressure applications, the double offset butterfly valves are among the best options with all the functions and advantages they offer.

Get connected with us to know more!