Trunnion mounted ball valves are quarter-turn valves used to stop the flow of medium in pipelines. These valves feature a round or spherical disk in the center that rotates to start or stop the flow. This disk is called a ball and it features a hollow center. Ball valves are extremely versatile and are commonly used in industrial applications where tight shut-off is required.

Trunnion mounted ball valves feature additional support for the ball. This support is in the shape of a shaft and is called a trunnion. The trunnion absorbs any added pressure from the flow, reducing stress on the ball and seats of the valve. Trunnion mounted ball valves are used in high-pressure, large scale applications where low operating torque is required.

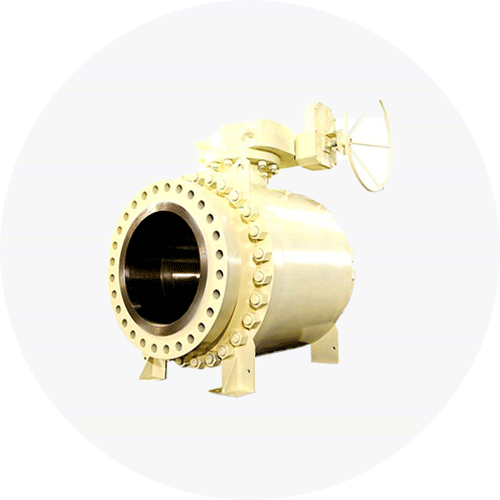

Trunnion Mounted Valves

How is a Trunnion Mounted Ball Valve Constructed?

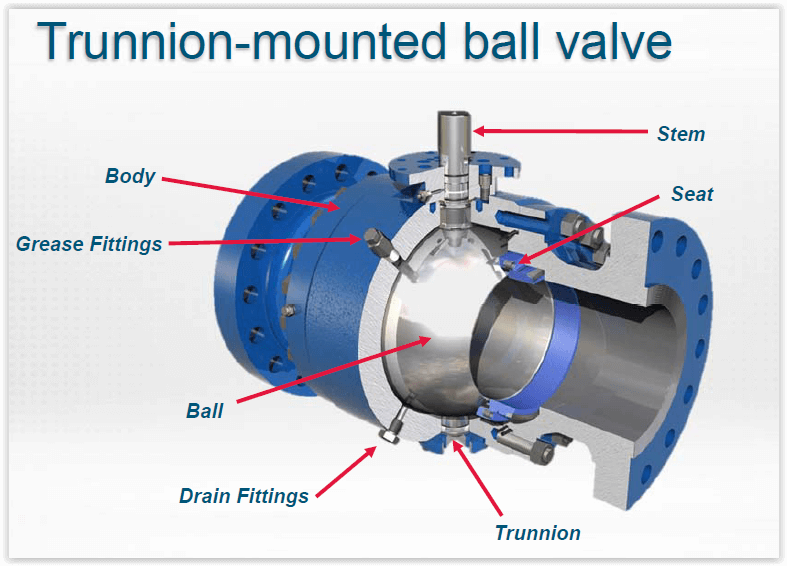

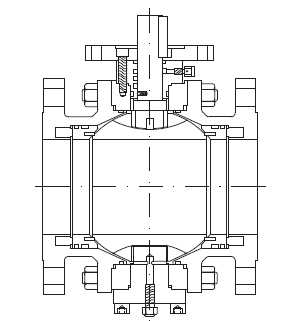

Trunnion mounted ball valves have a similar structure as traditional ball valves. The only difference is that trunnion ball valves have additional mechanical anchoring that supports the ball or disk. In this design, the ball is supported from both ends on the x-axis, so that it stays in place and is easy to control. Here is a look at the different parts of a trunnion-mounted ball valve.

Body

The body of the valve is the casing that holds and protects the internal parts of a trunnion mounted ball valve. It can be made of carbon steel, stainless steel, low-temperature carbon steel, duplex, super duplex, Inconel, and more depending on the application. While metal seat ball valve and carbon steel ball valve are very suitable for high-temp applications.

Stem

The stem of a trunnion mounted ball valve connects the ball to the actuator. It is connected to the ball through welded joints and it controls the movement of the ball. Trunnion ball valves have reinforced anti-blowout stems, that’s why they can handle cryogenic and high-temperatures without sustaining any damage.

Seats

The seats of a trunnion-mounted ball valve surround the ball. When the actuator is turned, the seats hold the ball snugly in place, sealing off any access. Trunnion ball valves have spring-loaded seats that move towards the ball as it is held firmly in place.

Trunnion

What is trunnion in a valve?In a trunnion mounted ball valve, there is an additional shaft that holds the ball in place from below. This small shaft is known as a trunnion and it keeps the ball firmly in place. In some ball valves, the trunnion is an extension of the ball while in others it is connected to the ball through welded joints.

Disk

The disk in a trunnion mounted ball valve is in the shape of a perforated, solid ball. The ball is connected to the stem on one end and the trunnion on the other. In a trunnion ball valve, the ball or disk is held in place while it rotates. The seats are always in contact with the ball, hence reducing torque.

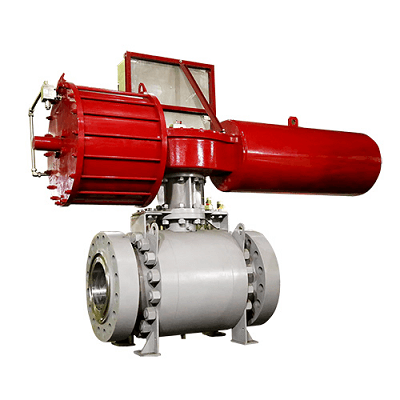

Actuator

The actuator in a trunnion ball valve is used to open or close the valve. There are different kinds of actuators used in ball valves depending upon the application and medium such as air operated ball valves. Bare stem, gear, hand lever, pneumatic actuator, and hydraulic actuator are some common actuators found on the valve. You can also use a gas actuator, gas-over-oil actuator, motor-operated actuator, hydraulic/electric actuator, hydraulic-operated actuator, and more.

Types of Trunnion Mounted Ball Valves

Trunnion mounted ball valves are available in many different configurations. They are highly customizable so you can choose the size, type, and actuator that suits your needs. China also has the best trunnion mounted ball valve manufacturers for you to choose. Here are some common types of trunnion ball valves.

Based on Body Configuration

Body configuration determines how a valve can be accessed for maintenance or repair. There are two types of trunnion mounted ball valves based on body configuration.

Top Entry Trunnion Mounted Ball Valve

This type of ball valve has a removable bonnet cover on the top of the valve. The internal parts of the valve can be easily accessed by removing the bonnet. These valves are easy to assemble and disassemble. You can repair or maintain different parts of the trunnion valve without removing it from the pipeline.

Source: SIO Top Entry Trunnion Mounted Ball Valve

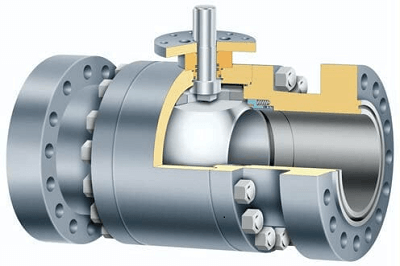

Side Entry Trunnion Mounted Ball Valve

Side entry ball valves are also known as split body trunnion mounted ball valves. In these valves, the body is divided into two or three pieces that are bolted together like flanges. One piece of the body is always larger than the rest. The larger piece holds the ball as well as the stuffing that goes around the ball. These valves are easier to inspect and repair as the smaller piece can be removed to access the valve.

Source: https://hardhatengineer.com

Based on Bores

The bore of the valve is the hole that is found in the middle of the disk or ball. Trunnion mounted ball valves have two types based on bore size.

Full Port Trunnion Mounted Ball Valves

In full bore valves, the size of the diameter of the bore matches that of the connected pipeline. When the valve is open, the medium can flow freely without restriction through the bore. This type of ball valve is used in chemical, petrochemical, and refining industries. They are also used in applications where pigging is required.

Half Port Trunnion Mounted Ball Valve

A half port trunnion valve has a bore size that is a few nominal sizes less than the diameter of the connected pipeline. The flow path of the medium is restricted which results in higher energy losses. Half port valves are mostly used in the oil and gas industry.

Based on Assembly

The body of the valve may have one, two, or three pieces connected together though welded joints. There are two types of trunnion mounted ball valves based on the number of pieces.

Two-Piece Trunnion Mounted Ball Valve

This valve features two pieces of housing that are connected to each other through threaded connections. It is easy to open up one piece of housing to access the valve for cleaning or repair. However, the valve has to be disengaged from the pipeline before the housing can be removed.

Source: SIO Two-Piece Trunnion Mounted Ball Valve

Three-Piece Trunnion Mounted Ball Valve

Three-piece trunnion mounted ball valves go one step ahead of the two-piece design. They have three pieces of housing that are bolted together. You can remove one piece to access the inner parts of the valve for repair and maintenance. But you don’t need to disengage the valve from the pipeline to do so.

Source: SIO Three-Piece Trunnion Mounted Ball Valve

How do Trunnion Mounted Ball Valves Work?

Trunnion mounted ball valves are quarter-turn valves. This means you need to turn the actuator on a 90-degree angle to turn the valve on or off. Once the actuator is turned the ball rotates so that the bore faces the pipeline and medium can flow freely. Another turn of the handle moves the ball so that the bore faces away from the pipeline stopping the flow.

For example, you have to regulate the flow of oil through a critical process unit. You will install a three-piece, half-bore, split-body ball valve like SIO Trunnion Mounted Ball Valve to get the job done. To start the flow of oil, you will move the actuator on the valve 90 degrees one way (usually clockwise). The actuator is connected to the stem of the valve which in turn is connected to the ball. As the stem rotates it moves the ball as well so that the side of the ball with the bore faces the pipeline. Since this is a half-bore valve the flow of oil is restricted, lowering the pressure with which the stream flows.

To stop the flow, you rotate the actuator again moving both the stem and the ball. The bore of the ball now faces away from the pipeline inhibiting flow. The upstream pressure on the valve pushes the seats closer to the ball so that they make a tight seal. Since the seats of a trunnion mounted ball valve are spring-loaded, even low pressures can push them against the ball. This tight seal stops the flow of oil and also prevents oil from getting into the internal parts of the valve.

Trunnion mounted ball valves are used in both high-pressure and low-pressure applications. In high-pressure applications, the valve maintains its torque as any added pressure on the seats and ball is absorbed by the trunnion. In low-pressure situations, the valve’s spring-loaded seats move closer to the ball to form a firm seal.

What are the Applications of Trunnion Mounted Ball Valves?

Trunnion mounted ball valves are extremely versatile. They are used in many different kinds of industries because of their customizable features. For example, SIO Trunnion Mounted Ball Valve features O-rings and fire-safe stem packaging that prevent leakages. It also comes with stainless steel sealant injection fittings for emergency stem or seat sealing. Trunnion mounted ball valves are used widely in chemical, petrochemical, oil and gas, LNG, hydrocarbon industries. Trunnion Mounted Ball Valves are also a common valves in water distribution systems and marine.

Source: SIO Trunnion Mounted Ball Valve

Ball valves are also used for many different kinds of applications including skids like turbine, compressor, generator, and separator, field gas, polymer, LNG, crude oil, and industrial gas processing plants, diesel process, tank farms, automated process applications, hydrocarbon processing, and oil refinery feedstock lines. Trunnion mounted ball valves are suitable for both large scale high-pressure applications and compact, low-temperature situations.

What are the Advantages of Using Trunnion Ball Valves?

Trunnion mounted ball valves are very popular in the piping industry. That is because they can handle different kinds of applications and mediums including liquid, gasses, and slurries. Here are some of the most favorable advantages of using trunnion mounted ball valves.

No Size Limit

Trunnion mounted ball valves can be found in all kinds of sizes. Two and three-piece ball valves can house large sized balls so they are perfect for larger applications. Single unit trunnion mounted ball valves can be used for smaller, low-pressure applications. Since they can handle high-pressure operations, trunnion mounted ball valves are also suitable for critical operations.

Customizable Features

Trunnion mounted ball valves can have many value-added features. You can fortify the seats and the ball with injections to make them seal tightly. The bearings and bolts can be made corrosion-resistant increasing the valve’s longevity. Larger valves can be equipped with lifting lugs.

Spring-Loaded Seats

The basic difference between floating ball valves and trunnion mounting ball valves is that the latter has spring-loaded seats. In a floating ball valve, the pressure of the onstream forces the ball to move towards the seats creating a seal. However, the ball needs high pressure to do so. This makes floating ball valves ineffective in low-pressure situations. In trunnion-mounted ball valves the pressure from the onstream activates the spring-loaded seats so that they move towards the ball that is held in place by the trunnion. This creates a tighter seal and makes the valve efficient in both high and low-pressure situations.

Ease of Operation

Any added pressure on the valve is absorbed by the trunnion and the stem. This means the valve needs a lower operating torque and a smaller actuator. This reduces costs and makes it easier to operate the valve. Three-piece trunnion mounted ball valves are also easy to repair, clean, replace, and maintain as you only have to remove one piece to access the working parts of the valve.

Double Block and Bleed Capabilities

One of the stand-out features of trunnion mounted ball valves is that they can have a double block and bleed capabilities. You can use multiple trunnions mounted ball valves to make a double block and bleed valve. Or add a bleed body to a two-piece or three-piece trunnion ball valve to help improve its sealing abilities. The double block and bleed function makes it possible to flush the valve under pressure and verify that the seats are sealing properly.

Trunnion Vs. Floating Ball Valve

Valve trunnion are those devices that are responsible for fluid flow in a machine. The valve trunnion role is essential in manufacturing plants and even domestic applications. The term ‘valve’ is broad in its types and applications, and two such types are trunnion and floating ball valve. The following criteria differentiate them:

Trunnion Ball Valves:

Trunnion mounted ball Valve consist of a ball on the base fixed on a trunnion. Ball valve trunnion mounted is further pulled together to a stem. The essential difference that sets apart trunnion ball valves from floating ones is that there is the least amount of friction involved, enabling smooth flow of fluids and less pressure. It also does not require much torque. Most manufacturing plants use a trunnion ball valve with strongly welded components.

Pros

- Less torque: Trunnion mounted ball valves do not require much torque forces to operate, unlike floating ball valves that rely on torque.

- Versatile: Trunnion mounted ball valves are versatile, meaning that they can be used for both small-scale domestic applications as well as large-scale manufacturing operations

- No friction: Trunnion ball valves provide little to no friction and pressure on the walls, preventing compartmental depletion

- Full sealing: Trunnion ball valves secure the openings fully

Cons

- Expensive maintenance: As Trunnion ball valves are strongly joined together through the welding process, their maintenance and repair can be an expensive ordeal. Ball valve trunnion mounted can also be difficult to put them back together once broken. Hence, they disturb the normal manufacturing process.

- Obligatory repairs: Sacrificing maintenance can decrease the quality of its working by increasing the degree of friction. As trunnion ball valves are welded together, regular maintenance is a must.

Applications

As already mentioned, a trunnion ball valve is versatile and can be put into many different uses. Some of its common applications are as follows:

- Chemical manufacturing operations: These plants have a lot of movement of fluids. These gasses and liquids are transmitted over long distances via trunnion ball valves. They are extensively used when there are acids and strong bases, as high temperatures can damage the surrounding operators and cause danger. The trunnion ball valve’s security and sealing helps it withstand high temperature and thus prevent such situations from taking place.

- Petroleum industry: Another place where trunnion ball valves are put into action is in petroleum and other fuel industries. Normally, petroleum operations choose those ball valves that adhere to API 6D standards of manufacturing and application as trunnion ball valves are sturdy enough to withstand extreme conditions during operations. Large-scale industries prefer those ball valves which can prevent leakage and withstand extreme pressures to which they are exposed.

- Power industry: As power is derived from the movement of various fuels, transferring these essential fluids without leakage or wastage becomes essential for power-driven industries. Here, trunnion ball valves ensure high control over such resources, especially temperature and pressure.

Floating Ball Valve

Definition

Floating ball valves are made by linking a ball to the step, leaving the bottom part to flow freely. Unlike trunnion ball valves, components in a floating one can flow freely, ensuring a high degree of flexibility. Floating ball valves have set rings which are essential for holding it intact. The big difference between the two is that floating ones are dual-directional, thus requiring high torque forces.

Pros

- Responsive: Floating ball valve is responsive to fluid flow, allowing flexibility in operations.

- Small-scale applications: Due to their size, it is extremely beneficial to use them even in small-scale operations. Floating ball valves are an efficient option to choose when the operations tend to be in the lower range.

Cons

- High torque: The incentive in managing high torque focus is quite high, making it an expensive option.

- High pressure: Floating ball valves possess high pressure during shut-off situations and are highly prone to damage.

Applications

- Emergency shut-off systems: Their highly responsive characteristic makes them an excellent choice for emergency systems. As floating ball valves are unmounted and not welded together, they can be a suitable option for the flow of fluids like fuels and water.

- Water distribution: Water systems often require the prevention of air pockets and smooth water distribution. They require optimal pressure levels and good controlling factors to withstand high forces. Due to the pressure-sensitive nature of floating ball valves, they are an ideal type of valve for handling high water flow.

Trunnion Double Block And Bleed (DBB) Ball Valves

Simply put, a DBB ball valve is a combination of 3 valves fit into one device that controls the flow of fluids. According to the API 6D standards, a trunnion double block and bleed ball valve has two surfaces that provide secure sealing from pressure. Both of these ends produce a cavity-like structure in closure form. There are varieties in DBB ball valves; some bleed with piping. These styles are used in different settings in the manufacturing arena. For instance, the double isolation and bleed valve (DIB) has a vent or bleed valve with separate seating surfaces.

There are a couple of different styles of double-block and bleed valves. It incorporates the dual direction function from the floating ball valve, enabling isolation of both surfaces.

They are used extensively in place of 2 distinct ball valves due to the immense amount of time and cost saving in their installation, maintenance, repair, and operation. Keeping in mind the weight of 3 ball valves on the pipeline, a trunnion DBB ball valve gains the upper hand by preventing heavy pressure and occupying less space. They are also beneficial in areas prone to fluid leakage, especially in chemical industries where handling corrosive liquids is a daily ordeal. In this way, they are extremely secure and safe to use.

Applications

Trunnion Double Block And Bleed (DBB) Ball Valves are normally used in industries where a high degree of pressure is involved, such as oil and gas lines. Especially in industries where cavity bleeding is an essential requirement, trunnion DBB valves can be used. They are also needed when piping lines need isolation from the environment. Their high usage in industries can be attributed to the many benefits. For instance, it avoids contamination of fluids and the operational environment and reduces maintenance costs by a marginal extent. They are used in the following places:

- Calibration of meters

- Fluid servicing needs, especially near municipal areas and water-prone districts

- Storage and transmission functions

- Sampling

- Steam processors

Buying Valves From Reliable Trunnion Ball Valve Manufacturer

It is a given that different manufacturers produce different qualities and types of ball valves. As such, getting a reliable trunnion ball valve manufacturer is an important decision for manufacturing owners. There are several factors to keep in mind while choosing one. One must consider the following:

- Product specifications: The first and foremost thing to consider is defining certain criteria that enable informed supplier selection. For instance, knowing the fluids involved can narrow the material specification and type of trunnion ball valves required. Additionally, knowing its applications can determine the configuration and specification of a suitable ball valve.

- Temperature and Pressure ratings: Accurately describing the minimum and maximum temperature and pressure is essential to choosing which type of ball valve would suit. Ultimately, it would narrow down the companies that supply those ball valves and make your choosing process straightforward. It is important to understand that the ball valve material and sealing degree can play an important role in adapting to the operational environment.

- Cost and Bulk Orders: Remember that custom trunnion ball valve manufacturers may demand more time than those who sell standard pre-made ones. Make sure to consider its lifespan when ordering in bulk.

- Certifications: Understanding the necessary certifications can help determine the credibility and integrity of the supplier. It can be said with confidence that those suppliers with certifications ensure the minimum standards required in a trunnion ball valves manufacturing setting with reasonable costs. Certain standards to look for are API 6D, API 598, NEMA, ANSI, and NSF.

- Lead time: Lead time can be crucial when considering the right supplier. While longer lead times can be beneficial, it is not always a good thing to have longer durations of waiting periods when dealing with highly dangerous material.

- Support: The last thing to consider, and the most crucial factor, is to know if the supplier is actively engaged with customers regarding satisfaction, specifications, requirements, and feedback.

Conclusion

Trunnion mounted ball valves provide tight shut-off in larger, critical, high-pressure operations and specialized low-pressure applications. The seats of the valve are always in contact with the ball making for tighter seals that prevent leakages. As one of the best high pressure ball valves manufacturers, SIO can help manufacture trunnion mounted ball valves that meet your requirements, whether it’s a three pieces valve or ball valve flange type. Our trunnion valves have bolted a three-piece body that incorporates double O-rings or a combination of O-rings and gaskets, suitable for buried or above-ground installation. They also feature double piston, self- relieving seats with Inconel® seat springs. Contact us for more information on how we can customize your trunnion mounted ball valves.

2 Comments

Very informative and useful

How to decide number of springs in trunnion mounted ball valves? please share the sample calculation if any

Thanks in advance

You need to disengage 1, 2 or 3 piece ball valve from pipeline for repair and maintenance. There is two type of trunnion design, shaft and plate.