What is a floating ball valve?

Floating ball valves are the most common type of ball valve used in the piping industry. They are quarter-turn valves that feature a disk in the shape of a ball. The ball is perforated and hollow allowing the medium to pass through it when the valve is open. Floating ball valves are used in many different kinds of applications.

Floating ball valves are capable of providing bi-directional sealing which is why they are used widely in oil and gas, water, and other industries. They are available in a number of different sizes and configurations, like air operated ball valve. You can also customize these valves to make them suitable for high-pressure operations. Floating ball valves are popular in industrial use because of the air-tight seal they provide when fully closed. In this blog we will discuss how floating ball valves are constructed and how they work. Read on to find out more.

Being extensively used in the piping industrial setting, one can notice the significance of a floating ball valve in maintaining certain levels of fluids. Floating ball valve regulate the movement of the liquid and are equipped with a dual-directional sealant, enabling proper pressure and temperature control. However, they are limited to medium-low degrees of tension. One can notice them in action in many industries involving the movement of gasses and liquids via massive pipelines, especially the oil and gas and petroleum industries.

Floating ball valve consist of a disc-shaped hollow ball that can penetrate and absorb fluids when opened. Depending on the supplier, floating ball valves can be seen in different varieties in terms of height and configurations. Valves are those devices that are responsible for fluid flow in a machine. Their role is essential in manufacturing plants and even domestic applications. Floating ball valves are made by linking a ball to the step, leaving the bottom part to flow freely. They have set rings which are essential for holding it intact.

The essential variation between the two is that floating ones are dual-directional, thus requiring high torque forces. A floating ball valve is responsible for maintaining a standard level in a fluid reservoir or a pipeline connected to the tank by controlling and regulating the flow. It is connected to the main water supply in the manufacturing setting, enabling the ball component to mount on top.

By working on the water-level principle, float ball valves are responsible for reaching and maintaining flow until a specific level has been reached. The ball floats on the level and ends the water flow once the tank is filled to an optimal level. The term ‘float ball valve’ has been derived through this process. There are several uses and applications associated with a floating ball valve. They comprise the following components:

- Main body

- Ball Float

- Bore

- Packing nuts

- Seat

- Stems

- Actuator

Floating ball valves consist of specific surface components called ‘seats’; this seating is responsible for compressing the floating ball in the valve’s main body. The name originates from the floating and penetrable ball surface inside the ball valve’s body. If the surface seating breaks apart, the ball goes into the stem and seals the opening, preventing the fluids from entering. This design provides a plan-B in case the seating disintegrates.

The step is responsible for maintaining upstream pressure. The ball component has a hole that allows liquids and gasses to pass through. However, when positioned at 90 degrees, the same ball acts as a sealant and closes the valve. Such a mechanism makes it dual-directional. Since the floating ball valve controls fluid movement, it can automatically close and open the entries and maintain pressure.

What Is a Trunnion Mount Ball Valve?

They consist of a ball on the base fixed on a trunnion. They are further pulled together to a stem. The essential difference that sets apart trunnion ball valves from floating ones is that there is the least amount of friction involved, enabling smooth flow of fluids and less pressure. It also does not require much torque. Most manufacturing plants use a trunnion ball valve with firmly welded components. While their function is significantly different from floating ball valves, each serves its purpose in the pipeline industry.

They are essentially quarter-turn ball valves that maintain and control the movement of fluids within the pipeline. Each side of the ball valve is connected to the stem and a shaft. This shaft, also called the trunnion, is responsible for maintaining the balance and momentum of the machine. The ball is fixed to its place through the trunnion. They consist of the following components:

- Main body

- Ball

- Seat

- Trunnion

- Stem

- Injection

As mentioned earlier, they are manufactured with a quarter-turn design that enables them to rotate and control the movement of fluids in a pipeline. As such, they are extensively used in the steam sectors. Like a floating ball valve, the ball component is made with a hole that allows the fluids to pass through it. With the hole projecting outward, a 90-degree turn will enable the ball to give the liquids, while another 90-degree turn will restrict the flow. One can see them in action in most shut-off operations due to their versatility.

The ball component (known as the trunnion) implements a low torque force by absorbing excess pressure from the hard and fast flow. It is helpful for large-scale industrial applications. They are built as an integration with the pipe. Most trunnion ball valves are manufactured by conforming to API 6D standards or API608.

How are Floating Ball Valves Constructed?

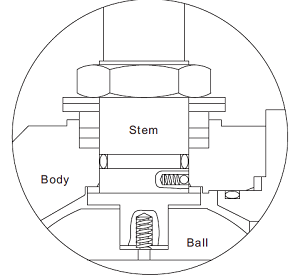

Floating ball valves feature all the basic components of a ball valve. In addition to these components, other add-ons like O-rings and extra packing can also be added to customize the valve. Here is a look at some of the main parts of a floating ball valve.

Body

The body of the floating ball valve houses all the moving parts. It may be a single unit or divided into different pieces. The body is designed to protect the working parts of the valve and make it easier to connect the valve to the pipeline. It is also the first pressure boundary of the valve. Floating ball valve body is usually made of carbon steel, stainless steel, low-temperature carbon steel, duplex, super duplex, inconel, and more.

Trim

The trim houses all the moving parts of a floating ball valve. These parts include the stem, ball, seats, and sleeves of the valve. The stem connects the actuator to the disk or ball. It is connected to a slot at the top of the ball and can move the ball to a quarter turn. Floating ball valves feature anti-blowout stems that can handle both medium and low temperatures. The disk in a floating ball valve is in the shape of a hollow ball. The hollow center of the ball is known as the bore. The ball is made of steel and has perforations on it for better sealing. It is connected to the stem on one end and has the ability to freely float in the valve. Floating ball valves feature two elastomeric seats. The seats have seal rings that provide tight shut-off when the valve is turned off and protect the seats against high-pressure when the valve is turned on.

Actuator

The actuator is what you use to open and close the valve. It is connected to the stem on one end so that when you move the actuator, the stem moves as well. Many kinds of actuators can be used with floating ball valves depending on the application and the medium. Some common types include bare stem, gear, hand lever, pneumatic actuator, hydraulic actuator, gas actuator, gas-over-oil actuator, motor-operated actuator, hydraulic/ electro actuator, hydraulic-operated actuator, and more.

How Do Floating Ball Valves Work?

Floating ball valves are shut-off valves that provide a tight seal in critical operations. They are suitable for low-pressure and certain high-pressure applications and can control the flow of liquids and gasses. Just like all other ball valves, they cannot regulate the flow of medium and should not be used for throttling purposes. Floating ball valves can either be fully open or fully closed.

For example, if you wanted to control the flow of water in a hydro-electric plant, you will install a floating ball valve like SIO API6D API 607 Floating Ball valve to the pipeline. The valve can be welded in or connected to the pipeline through bolts. To open the floating ball valve, you have to turn the actuator to a 90-degree angle. As the actuator moves, it turns the stem of the valve. The stem is connected to the ball and rotates it so that the hollow side is parallel to the pipeline. The water can now freely flow through the valve to the other end of the pipeline. The onstream pressure moves the ball slightly so it is in contact with the downstream seat, making a seal. This prevents water from getting into the valve body.

To close the valve, move the actuator a quarter turn again so that the ball rotates and the hollow side becomes perpendicular to the pipeline. The onstream pressure on the valve pushes the upstream seat and the ball to the downstream seat so that a tight seal is formed and the flow of water is effectively stopped. Floating ball valves provide bi-directional shut-off. This means the medium can flow from either direction without affecting the function of the valve.

Types of Floating Ball Valves

Floating ball valves have many different sizes, types, and configurations. They are very versatile and can be customized to suit any kind of application or pipeline such as carbon steel ball valve. Here are some common types of floating ball valves.

Based on Bore Size

The hollow center of the ball is called the bore. There are two types of floating ball valves based on bore size.

Full Bore Floating Ball Valves

Full bore floating ball valves feature a bore size that matches the diameter of the pipeline the valve is connected to. These valves allow the flow of medium without any restrictions and are suitable for liquid and gaseous mediums. In full bore floating valves, the onstream pressure from the pipeline affects the entire surface area of the ball, pushing it against the downstream seat more effectively. Full bore floating ball valves provide tighter seals than any other kind of ball valve.

Reduced Bore Floating Ball Valves

In reduced bore floating ball valves, the size of the bore is a few nominal sizes less than the diameter of the pipeline. These valves are suited for applications where the flow of medium needs to be restricted. They are mostly used in the oil and gas industry. In reduced bore floating valves, the onstream pressure from the pipeline affects a dedicated portion of the ball. This means a certain level of pressure is required to push the ball against the downstream seat. Reduced bore floating ball valves can only be used in applications where the pressure is high enough to achieve tight shut-off of the valve.

Based on Assembly

Floating ball valves can have one, two, or three pieces joined together through welded or forged connections. There are three types of floating ball valves based on assembly.

One-Piece Floating Ball Valve

This type of floating ball valve features a single cast or forged steel body that houses all the moving parts of the valve. Single-piece floating ball valves are available in different sizes and are the most compact type of ball valve. They are the cheapest floating ball valves available in the market and are widely used in smaller applications. Single-piece floating ball valves cannot be opened for cleaning, repair, or maintenance so they are mostly used with mediums like gasses where little maintenance is required.

Two-Piece Floating Ball Valve

Two-piece floating ball valves feature two pieces of housing that are either forged or cast together. One piece of the valve is always larger than the other and it houses all the moving parts of the valve. Two-piece floating ball valves can be opened for maintenance, repair, and cleaning. However, the valve needs to be disconnected from the pipeline to do so.

Three-Piece Floating Ball Valve

This type of floating ball valve features three pieces of housing or body. These valves are larger in size and more expensive. You can also find small-sized three-piece floating ball valves for compact applications. The three pieces of the body are forged to each other. One half of the body is bigger and houses all the moving parts of the valve. This type of valve can be easily maintained, repaired, or cleaned without having to remove the valve from the pipeline.

5 Differences Between Floating and Trunnion Mounted Ball Valve

The floating ball valve and trunnion mounted ball valve are the two most popular kinds of ball valves. They are frequently used in similar industries for both high and low-pressure operations like underground and energy. However, there is always debate on which of the two valves is better. Here is a look at the top 5 differences between floating and trunnion mounted ball valve.

Source: https://taurusdbbvalves.com

Construction

The first difference between floating and trunnion-mounted ball valves is in the way the valve is constructed. In floating ball valves the ball is only connected to the stem from one end whereas the other end is free. The ball is free to float inside the valve. In trunnion mounted ball valve, the ball is connected to the stem on one end and to another shaft called the trunnion on the other end. The ball is held firmly in place and can only rotate as the stem moves. You can easily distinguish between the two valves when you look at them as the trunnion mounted ball will have an added shaft at the bottom.

Type of Seats

In floating ball valves, the seats are usually made of elastomeric material. An elastomer is a polymer with viscoelasticity (both viscosity and elasticity). This soft material helps cushion the pressure from the onstream that pushes the ball to the seats. The seats in the valve directly manage all the pressure from the onstream. The seats in a floating ball valve have additional seal rings as well since they have to manage all the pressure. In trunnion mounted ball valve the seats are spring-loaded. Any additional pressure is managed by the stem and the trunnion.

Sealing Function

Floating and trunnion mounted ball valves both provide shut-off but have different sealing functions.

When floating ball valves are closed, the onstream pressure forces the upstream seat and the ball to the downstream seat forming a seal.

In trunnion mounted ball valves, the onstream pressure activates the spring-loaded seats and they move towards the ball sealing the valve.

So the main difference in their sealing function is that, in trunnion mounted ball valves the ball does not have free movement and it can only rotate as the stem moves while In floating ball valves, the ball is free to rotate as well as move sideways.

Application

Floating ball valves are more suited for medium and low-pressure applications. They usually have smaller diameters and only provide seal only from the downstream side. Floating ball valves are suitable for mediums like liquids and gasses. Trunnion mounted ball valves are suited for larger, high-pressure applications. Since the seats move towards the ball, the valve seals from both the upstream and downstream end. Trunnion mounted ball valves can be used with liquids, gasses, as well as slurry mediums.

Added Features

In floating ball valves the seats need a separate mechanism for releasing additional pressure. This is the reason why they are not suited for high-pressure situations. However, the seats in trunnion mounted ball valve are self-relieving so any additional pressure is handled without the need for a separate mechanism. Trunnion mounted ball valves can also have double block and bleed abilities. This enables these valves to be used in critical high-pressure, high-temperature operations.

What Is A Floating Ball Valve Used For?

As mentioned, floating ball valves are used in various applications concerning low-medium pressure and a reasonable temperature. They have a sleek and compact design, enabling them to cater to small-scale and large-scale industries. The strong sealing capabilities of a floating ball valve make it a great contender for pipeline industries. They are used in the following operations:

- Emergency shut-off systems: Their highly responsive characteristic makes them an excellent choice for emergency systems. As they are unmounted and not welded together, they can be a suitable option for the flow of fluids like fuels and water.

- Water distribution: Water systems often require the prevention of air pockets and smooth water distribution. They need optimal pressure levels and good controlling factors to withstand high forces. Due to the pressure-sensitive nature of floating ball valves, they are an ideal type of valve for handling high water flow.

- Pipeline pressure management: Oil and gas pipelines use floating ball valves extensively. They are essential factors in fluid movement and can also handle the high pressures and temperatures they are subjected to. They are used as an outlet for tension. Where trunnion-mounted ball valves can disintegrate and break apart, floating ones can provide optimal pressure management.

There are essentially 3 types of floating ball valves- one-piece, two-piece, and three-piece floating ball valves. In each case, the more significant component provides housing for the main ball body to reside. All three kinds enable the dual-directional flow. Compared to trunnion ball valves, they are incredibly compact and robust, enabling them to withstand small-scale and large operations. Chemical and natural gas industries, transmission lines, and storage facilities use floating ball valves as fluid transmitters. Their low torque forces are a huge reason why one can see them in industrial operations. Certain floating ball valve suppliers also allow customizable options for an affordable price.

Conclusion

Floating ball valves have many advantages like small flow resistance, simple structure, good sealing performance, and being cost-effective for certain size and pressure. They are used widely in the oil and gas and water process industry. As one of the best high pressure ball valves manufacturers, they are available in a number of sizes and can be customized to suit your needs in SIO, whether it’s a metal seat ball valve, three-piece ball valve or ball valve flange type. At SIO we can add value-added features like oval safety handle, locking device, easy automation – pneumatic actuator, T-handle, extended bonnet for insulation, and more. Get in touch with us to discuss your valve needs.