PSIG Vs. PSI:What's Their Difference

Share:

Pressure plays a huge role in the piping industry, and this is the reason valves are in great demand across every sector. Pressure is what makes things move from one place to another and for this to happen efficiently, the valve pressure has to be regulated by a mechanism that keeps it within the required limits in relation to the equipment being used.

There are two units of measuring pressure that we are going to explore: PSI and PSIG. We will look at what each of them represents, their differences, and how they are used to measure pressure in the piping industry. If you have always been interested to know more about pressure, then this is the right place.

Table of Contents

What is PSI?

Pascal is the commonly used unit of pressure that has been the standard for many years now. By definition, it is the pressure that is created when 1 Newton of force is distributed uniformly over an area of 1 square meter. For a better understanding of how this pressure is applied, there’s another unit called PSI which is Pounds Per Square Inch.

PSI is a non-SI unit of measuring pressure, an alternative option that gives you a more accurate representation of the exact ball valve pressure being applied on a given area. It is the exact amount of force that is exerted on an object and is expressed in pounds per square inch. PSI is widely used in a number of industrial applications discussed below.

What is PSIG?

Source: Pinterest

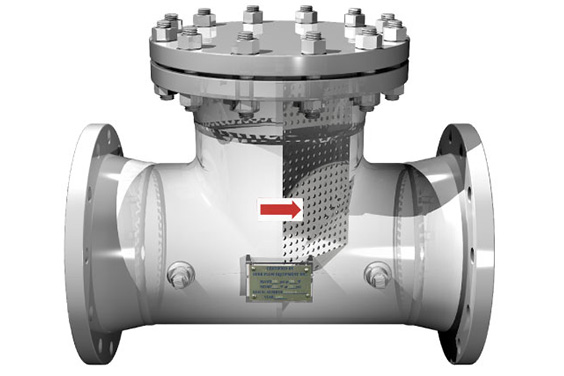

PSIG refers to the gauge pressure that is indicated in pounds per square gauge. It is a unit of pressure measurement that’s relative to the atmospheric or ambient pressure. In a nutshell, it is the kind of pressure measurement that excludes atmospheric pressure from the equation. The gauge pressure is recorded when the pressure inside a given system is bigger than the atmospheric pressure.

Applications of PSI and PSIG

Source: Pinterest

Both PSI and PSIG are used for a number of important tasks around the world, especially in the industrial complex. They are not the same, although the functions they are used for aren’t that dissimilar. The following are the most common applications of the two units of measurements.

Energy Conservation: Reducing power consumption has become a very important tenet of manufacturing, especially oil and gas processors and suppliers, and every company is trying to find ways of minimizing power usage as much as they can. Having an accurate pressure sensor is the most efficient way of ensuring you are not going overboard for something that requires less. Some of the most important innovations like wind engineering, ocean research, weather balloons, atmospheric studies. All these are processes that require accuracy, and using PSI and PSIG units is the best way to get around this.

Technology Industry: The technology industry is widespread across the globe, and it can be found in every other sector. For accurate measurements to be taken where essential processes like barometers, altimeters, airflow equipment, and printers, computer cooling systems, and so much more depend on accurate pressure measurements that can only be granted by proper units like PSI and PSIG.

Manufacturing Industry: The manufacturing industry is wide and makes use of all kinds of production techniques that require constant surveillance or else things will go belly up. The best way to determine the health of the machines being used is by monitoring their pressure, and this can be done accurately by using PSI and PSIG. Too much pressure can lead to accidents, and this is why pressure monitors and sensors can be found on every inch of the factory floor. They are ideal for sensing leads, air blades, material flows, keeping pneumatic controls in check, among many other roles.

Oil Refinery: Oil refineries are some of the industries that depend on proper pressure systems as they are used to transport gas and liquids, which rely on high pressure to move from one point to another. To ensure safety for those that deal with the operations, these pipelines have to be fitted with pressure monitoring gadgets that make use of PSI and PSIG principles. Using less or more pressure will not end well for the entire princess or the people involved with it.

Air Conditioning: The air conditioning industry, as well as the refrigeration industry, rely on pressure gauges to tell how the machine in question functions. The amount of air being released had to be within the parameters of what the machine is designed for; anything that goes overboard will only lead to wastage of power.

Heavy Machinery: Where automation is used in manufacturing industries, having pressure sensors is very important. They are what determines how pistons in the robotic arms and other heavy machinery have to function exactly as they are designed for. Gauging the right pressure amounts is what sets a successful manufacturing plant from one that keeps running into problems all the time due to mechanical failures.

Differences Between PSI and PSIG

Source: Pinterest

As we previously mentioned, there’s not much that separates PSI and PSIG as far as functionality is concerned; however, they do operate in different environments, with the latter used for measuring pressure that’s devoid of atmospheric pressure. The following are the distinct differences between the two.

Basics

PSI (pounds per square inch) is a non-SI unit of pressure measurements found in the Imperial system of measurements and is expressed in pounds per square inch of area. The official unit of pressure is Pascals and PSI focuses on the pressure exerted on a square inch of space. PSIG, on the other end, is pounds per square inch gauge and is a measurement that focuses on the pressure of a given area in relation to the surrounding atmospheric pressure, hence the last letter G.

Calculation

PSI can be easily converted to a number of units that are commonly used to measure pressure, Pascal, for instance. This is the reason why it is a commonly used unit of measurement the world over.

1 PSI equals 6894.76 Pascals. In the same breath, a single PSI pressure is equivalent to 2.31 feet of water. This unit has been used to help deep-sea divers, and submarines figure out how deep they can go without endangering the lives of the people on board. Prominent comparison units of PSI include the following.

1 PSI =.

- 0.068046 atmospheres

- 0.0689476 Bar

- 6894.76 Pascals

- 51.7149 Torr

- 2.03602 inHg

- 27.7076 inches of the water column

PSIG, on the other hand, is a little straightforward since it doesn’t include atmospheric pressure. Therefore, a PSIG counter will read 0 pounds per square inch when it is at sea level if the pressure source is not connected.

Conclusion

Keeping an eye on the high pressure is as important as monitoring all the other conditions like high temperature, both of which are common in most manufacturing processes. The devices used for this work are many and diverse, but the most important part of keeping in mind is the unit of measurement.

The choice to go with PSI or PSIG comes down to the nature of the task at hand and the quality of the valves that you are best comfortable with. For more information on how these units function, check out our website, and all the questions you may have will be answered by a team of experts.