Source: Pinterest

A lot of people don’t realize what a ball valve is until they have a problem with one. Just like most mechanical parts that keep our lives operating smoothly. Ball valves are effectively performing their duties in practically every facet you see around.

Ball valves are utilized in a variety of industries, including the food industry, health care, and numerous household products. These valves do not require sophisticated technology to keep liquids and gasses flowing in the appropriate direction. This guide will go over the many varieties of ball valves, as well as how they work and their applications. Read on.

What is a ball valve?

Source: Pinterest

So what is a ball valve? A ball valve is a type of valve that controls the flow of a medium through itself by means of a hollow, revolving ball. The valve is open if the ball’s hole is parallel to the flow, and it is closed when the valve handle is used to pivot the ball ninety degrees. A ball valve’s principal purpose is to isolate elements of a plumbing system by controlling the flow of a medium, typically water, air, or gas between distinct chambers, ducts, and pipes.

This is accomplished by allowing the medium to flow freely through the ball valve, allowing the medium to flow partially through a constricted hole, or totally halting the flow. Depending on the valve type and handle position, ball valves can also be used to redirect flow in multiple directions. Ball valves are versatile and long-lasting valves that are available in a variety of materials and sizes.

Because of its simple design, you may easily have them custom-fitted. The key limiting element for a ball valve is the application for which it is required. A PVC ball valve may suffice for low-pressure, low-temperature applications, but a stainless steel ball valve may be required to stop the flow of materials that are hot or under a lot of pressure. Not all ball valves are actuated by hand. When electrical current is sent through them, some, such as the electric ball valve, open and close.

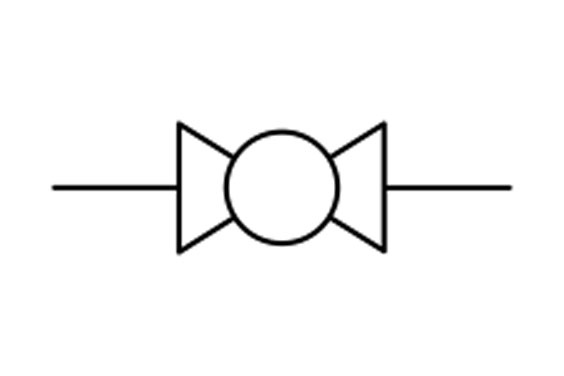

Ball valve symbol

Source: Google

Valve symbols are divided into two categories: generic symbols and symbols with modifiers. Generic symbols will indicate that a valve is present in the line, but they will not specify the sort of valve. The valve symbol with a modifier, on the other hand, indicates the specific type of valve utilized in the pipeline. For a ball valve symbol, there are two P&ID symbols.

The reason for this is that P&ID and isometric drawing symbols differ from one firm to the next. As a result, whenever you change companies, you should be aware of this. Similarly, the ISO symbols for butt, flanged, and socket end ball valves can be seen. In the diagram above, ball valves are symbolized by two equilateral triangles pointing towards each other, with a ball in the middle.

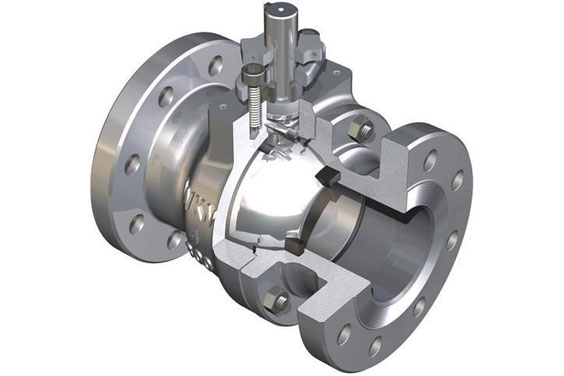

Common types of ball valves

Source: Pinterest

Ball valves are classified using a number of different approaches like caliber size, a form of connection, sealing form, pressure size, location of channel, temperature, and according to runner type. Ball valves play a big role in different industries depending on what they are used for. We have different types of valves performing different tasks. The below guide will outline and explain a few types of ball valves. Learn more.

Floating Ball Valve

Source: Pinterest

The ball is retained in place in a floating ball valve by the compression of the two elastomeric seats against the ball. Inside the valve body, the ball is free to float. The stem is attached to a slot on the top of the ball, allowing it to revolve a quarter-turn. Because of the upstream pressure pressing on the ball, the shaft allows for a certain degree of lateral movement of the ball.

In fact, this slight lateral movement places a strain on the ball, pressing it against the downstream seat, improving the valve’s leak tightness. The bi-directional shut-off is possible with this valve design. When the upstream pressure is high, the floating valve is extremely difficult to operate.

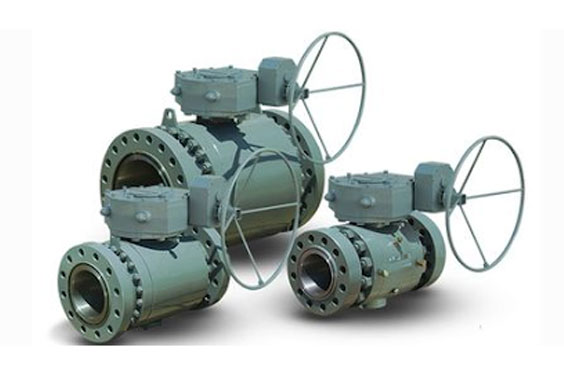

Trunnion-Mounted Ball Valve

Source: Pinterest

The problem of excessive torque required by a floating type valve in high-pressure use is solved with a trunnion-mounted valve. A trunnion is a small shaft that is placed into the body, similar to an extension. Ball valves with trunnion mounting provide additional ball support.

A trunnion is a type of support that is in the shape of a shaft. The trunnion absorbs any additional flow pressure, relieving strain on the valve’s ball and seats. Ball valves with trunnion mounting are utilized in high-pressure, large-scale applications that need a low working torque.

3 Way Ball Valve

Source: Pinterest

The most prevalent forms of ball valves are two-way and three-way valves. Three-way ball valves are particularly handy since they can be set up in a variety of ways to make gas and fluid flow management easier.

Three ports or apertures on a three-way ball valve allow gas or fluid to pass through and are connected to pipes or tubing. Depending on the flow direction through the valve, these ports are commonly represented as one inlet and two outlet ports or one outlet and two inlet ports.

Top-Entry Ball Valves

Source: Pinterest

They are similar to a globe valve in that it has a body and a cap, but the trim is made of a ball type. It is made up of a single entity. Cast metal is commonly used for these ball valves. Since it is created from casting, further NDE testing would be required to guarantee that the casting process is defect-free. These valves are frequently employed in applications where only minimum disassembly is required for in-line repair of internal components.

Full Port Ball Valve

Source: Pinterest

A full port ball valve, also known as a “full bore” valve, is a unique valve design that allows for unrestricted flow when the valve is opened. The bodies of full port valves are larger than those of standard valves. Inside this larger body are a larger ball and a larger aperture.

The openings of full port valves are the same size as the surrounding pipe. A 2″ full port ball valve, for example, will work with a 2″ pipeline and have a 2″ valve opening inside the ball. This is ideal for applications requiring minimal to no flow loss. It’s as if a full port valve isn’t present at all while it’s in the “on” or open position. The flow of information is unrestricted.

Standard Port Ball Valve

Source: Pinterest

The flow channel through a standard port is straight, but there is a flow restriction that causes a pressure decrease when the flow goes through the valve. The port and ball of a standard port ball valve are smaller than those of a full port ball valve.

It is less expensive however, due to the pipe size, it has a little reduced flow. They have bigger pressure drops than other ball valve varieties but are less expensive. Standard port valves, like full port valves, are suited for large flow systems.

V-Port Ball Valve

Source: Pinterest

The design of the ball is represented by the V in the v-port ball valve. You can better manage the opening and closing with a V ball valve. This type of flow has a linear flow characteristic. Ball valve manufacturers had to come up with a more durable design for these ball valves due to the high velocities of the fluids utilized with them, as these fluids can quickly harm a regular valve.

Multi-Port Ball Valve

Source: Pinterest

Three- or four-way ball valves with a L to T-shaped aperture in the center are known as multi-port ball valves. The L valve connects the central port to the side ports, while the T valve connects any two ports. A multi-port ball valve’s entrance is normally orthogonal to the outflow plane. The X port on 4-way ball valves is two L-shaped openings in the ball. Pipe-end connections can be made in NPT, flanged, or tri-clamp designs using the multi-ported flange end body.

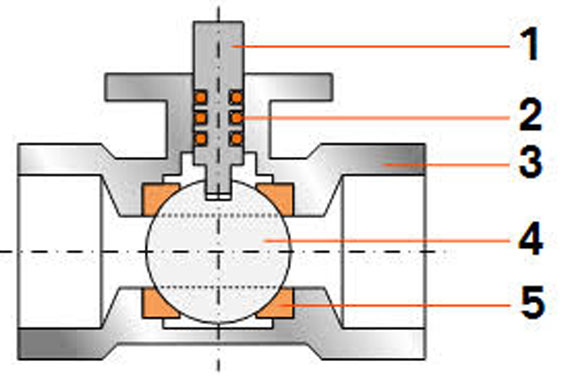

What are ball valve parts?

Source: Google

Ball valves are made up of a number of important components. All of these elements are active simultaneously. Let us have a look at what they are and what they do in the ball valve system. Continue reading.

Body of the Valve. This is the most vital part of the valve since it houses all of the control components. Offers maximum protection to all the valve components to ensure they function effectively.

Rotary Ball. The key feature of ball valves that distinguishes them from other valve types is a ball with a center hole through which the medium flows. The entrance and outlet are connected by a hole in the ball that runs across one axis. The ball’s direction is controlled by the Stem. The ball can be free-floating or attached to a trunnion. The working torque of trunnion-mounted ball valves is about 2/3 that of floating ball valves.

Stem. The ball is now connected to the external control mechanism. The stem of a manual ball valve, for example, is connected to a handle or lever.

Seats. The discs that sit between the body and the ball are called intervertebral discs. Seats act as a barrier between the two, as well as provide support for the ball.

Power Source. The stem of the ball valve is rotated by manual or triggered power sources. Operator-controlled levers and handles are examples of manual actuation. There are other automated power sources like electric, pneumatic, and hydraulic actuation.

Packing. This is a seal that keeps the media from escaping around the stem.

Bonnet. The bonnet is visible in the ball valve’s body hole. At the second stage, the bonnet is employed to cover this opening and, like the body, it acts as a pressure boundary. To complete the task, the bonnet keeps the ball and stem assembly in place, and its cap is connected to the body.

What does a ball valve do?

Source: Pinterest

A ball valve is a shut-off valve that regulates the flow of a liquid or gas by utilizing a rotatable ball with a bore. Turning the ball a quarter rotation around its axis allows the medium to flow through or be restricted. They have a long service life and provide good sealing throughout the valve’s life, even when it is not in use.

The easiest operation of a ball valve is to use a wrench or lever that the operator manually turns. Apply torque to rotate the lever arm 90 degrees clockwise or counterclockwise to open and close the valve. It shows that the valve is open if the lever arm is parallel to the pipe. On the other hand, if the lever arm is perpendicular to the pipe, this indicates that the valve is closed.

The ball valve’s functionality is restricted to turning it on and off. The use of a ball valve for the throttle is not suggested because the ball valve lacks precision flow adjustment. Ball valves can also be utilized as a control valve in some instances. Because the flow rate control precision is less precise than with other types of control valves, this application is less common.

What are ball valve applications?

Source: Pinterest

Ball valves are used in a variety of applications, and because the sealing ring of the ball valve seat is typically made of plastics, fire resistance and fire-proofing must be considered when selecting the structure and performance of the ball valve, particularly in the petroleum, chemical, and metallurgical industries. When employing ball valves, inflammable, explosive media equipment, and pipeline systems, fire resistance and fire-proofing should be prioritized.

Ball valves are recommended for double-position regulation, strict sealing performance, mud, wear, necking channel, quick opening and closing, high-pressure shut-off, low noise, cavitation and gasification, small leakage to the atmosphere, small operating torque, and small fluid resistance in the pipeline systems.

Ball valves are also ideal for light-structure pipeline systems with low-pressure shut-off and corrosive medium. Low-temperature devices and pipeline systems can also benefit from ball valves. Ball valves that have been through a rigorous degreasing process must be utilized in the metallurgical industry’s oxygen pipeline systems.

In oil and gas pipelines, full diameter welded ball valves must be utilized when the main pipeline must be buried beneath the ground. When performance regulation is required, special ball valves with V-shaped apertures must be employed. Metal-to-metal sealing ball valves can be utilized in pipelines with operating temperatures of above 200 degrees Celsius in the oil, petrochemical, chemical, electric, and urban building industries.

How Does A Ball Valve Work?

Source: Pinterest

A ball valve is a device that permits fluid to flow in one direction. These valves have two ports: one is majorly used for media input and the other one for media output. since they only permit material to flow in one direction, they are also called one-way valves.

A ball valve is a shut-off valve that uses a ball with a hollow section to regulate the flow of a liquid or gas. The medium can flow through or be blocked by rotating the ball a quarter-turn around its axis. They have a long service life and provide effective sealing even when the valve is not in use making them one of the most durable plumbing valves you can use.

A wrench or lever that the user manually twists is the simplest way to operate a ball valve. To open and close the valve, apply torque to the lever arm and move it 90 degrees clockwise or counterclockwise. When the lever arm is parallel to the pipe, that means the valve is open. When the lever arm is perpendicular to the pipe, however, the valve is closed.

The flow velocity of a system is used to control check valves. The disc will raise and enable the fluid to pass through once the system achieves the cracking pressure or the minimum upstream pressure required for the valve to work. The disc will automatically stop the valve to prevent fluid from passing through if the fluid pressure drops or the flow direction starts to reverse. Backflow is reduced as a result of this.

The application for which a ball valve is required is the most important limiting factor. For low-pressure, low-temperature applications, a PVC ball valve may suffice, but a stainless steel ball valve may be necessary to stop the flow of hot or high-pressure materials. Hand actuation isn’t required for all ball valves. Some, such as the electric ball valve, open and close when electrical current is passed through them.

Ball valve Installation And Maintenance

Source: Pinterest

Ball valves need proper installation and maintenance to avoid future leakages of fluids that might be disastrous. Below are the steps for proper ball valve installation.

- Examine the ports, seating surfaces, and threads of the ball valve to ensure they are clean and free of extraneous debris.

- Change the valve’s position from fully open to fully closed.

- Make sure the threaded pipe connection that is screwed into the valve is properly screwed in, clean, and free of debris and metal debris.

- Apply high-quality pipe thread sealant or PTFE thread sealing tape as directed by the manufacturer’s application to ensure a leak-free seal on the pipe joint.

- Valves and pipelines must be aligned to avoid thread crossings. The male thread must be aligned with the thread axis. Maintaining the correct pipe orientation during assembly prevents unnecessary stress on the valve body. By connecting the pipe, the valve and the pipe are supported in a straight line so that unnecessary stress is not applied to the valve body.

- When putting in two-piece frame ball valves constantly use wrenches while making up pipe joints to those valves. Position one wrench at the valve ceases closest to the pipe joint being tightened and the alternative wrench onto the pipe to save you transmitting torque via the valve frame joint, among the valve frame and tailpiece.

- Tighten until the joint begins to feel and the fitting is almost in the desired direction. Next, increase the tightening force a little. It will move less with each attempt, so it will continue to pull until it is properly aligned and successfully connected.

Ball valves are low-maintenance components. Apart from worn O rings that seal the ball inside the valve body, all the valve requires is a little oil to maintain it clean and free-turning. When a valve’s lubricant wears down and dirt or corrosion accumulates, it might become difficult to turn.

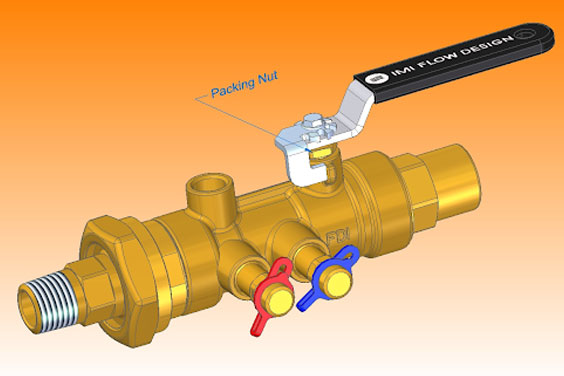

Ball valve packing

Source: Google

A ball valve is a type of valve that has a Packing is a flexible seal that fits around the shaft of the valve and prevents the media flowing through it from leaving. It’s a one-piece packing that keeps the valve element in the valve cavity. At room temperature, the single-piece packing is drawn over the valve element or molded on.

A flow control element, such as a ball, and upper and lower trunnions, may be included in the valve element. The bottom trunnion may extend past the packing’s lower end. The valve packing keeps the media from escaping through the stem aperture in the bonnet and into the valve body. Chevron V-ring packing is the most prevalent style of packing nowadays. The cross-section profile of this packing resembles the letter “V” when viewed from the side.

The packing’s outer diameter corresponds to the bonnet’s bore. The interior diameter of the stem is the same as the outside diameter. The stem is put through the packing and multiple rings of this packing are placed on top of each other. The top of the “V” is pushed down by a packing gland on the bonnet, which causes the packing to expand and seal against the stem and bonnet.

What to consider before buying ball valves?

Source: Pinterest

Ball valves have a unique design and are capable of controlling a wide range of fluids. Choosing the best for your application can be a bit challenging. The work is made harder by the fact that there are so many valves on the market. While looking for the best Ball Valve, there are a few things to keep in mind:

1. Material

The ideal materials for your ball valve will be determined by the sort of liquid or gas traveling through it. Stainless steel, PVC, brass, and bronze are some of the most frequent materials used to make ball valves. Teflon is commonly used to make the seat. However, other synthetic polymers or metals may also be used. The valve body and seals must be made of materials that are compliant with temperature and pressure specifications. Here’s a closer look at the different types of materials:

- PVC. This is a type of plastic used in the manufacture of ball valves. One of its benefits is that they are flexible and smooth, allowing ball valve elements to move more easily.

- Bronze and brass. Ball valves used in systems with low or medium pressure should be made of these two materials, bronze or brass. These materials are also resistant to water and corrosion.

- Stainless steel. This material is very important when it comes to the creation of various ball valve types. That is because it has many beneficial properties such as durability and corrosion resistance. Stainless steel ball valves can be employed in geochemical and general plant systems. When it comes to pressure rating and temperature tolerance, it outperforms cast iron, ductile iron, brass, and copper

- Iron. Iron is a popular material for making ball valves because it can tolerate a wide variety of pressures and temperatures. But it is also important to note that it’s not as strong as PVC.

- CPVC( Chlorinated PVC). PVC and chlorinated PVC are fairly similar, however chlorinated PVC can withstand greater temperatures. This material is appropriate for use in ball valves that handle hot water.

- PTFE. Most ball valve seals are made of polytetrafluoroethylene, which is compatible with practically all forms of media. Despite the high melting point of this material, it is suggested that applications involving extremely high temperatures utilize metal or ceramic sealing.

- Elastomers. Certain ball valve designs also use elastomers. When using elastomer-based valves, make sure the material is appropriate for the media in your application.

2. Design

Ball valves come in a wide range of designs. The different types of ball valve designs include the DVB/DIB design, single/double effect design, floating and trunnion mounted design, body types (split, top entry, and welded body), soft seated and metal seated design, and last but not least reduced bore ball valve and full bore design.

3. Ball valve standard

As a rule, all ball valves must pass through a number of test standards. They should be tested in accordance with EN 12 266–1, which includes shell strength tests P10, P11, seat tightness tests P12 (water pressure 1,1PN and air pressure 0,6 MPa), and leakage rate A – zero leakage.

API 598 or API 6D – zero leakage – are used to test ball valves according to American specifications. Additional tests may be performed if the consumer requests them. Here are some of the standard tests discussed in detail.

ANSI. The American National Standards Institute is a not-for-profit organization that develops product and process conformance standards. These voluntary guidelines aim to ensure that valve performance, manufacturing procedures, and valve services are all consistent.

Copeland follows these tight rules to ensure that you obtain high-quality goods you can rely on, even in the most demanding or crucial situations. ANSI ball valves are subjected to numerous tests by the American National Standards Institute. The standards, such as ANSI Z21.15, are stamped on the ball valve.

Uniform Plumbing Code (UPC). All Plumbing goods including ball valves must meet the Uniform Plumbing Code (UPC) and the Canadian Uniform Plumbing Code (cUPC) to be safe and sanitary.

Underwriters Laboratories (UL) Valve bodies are tested three times by Underwriters Laboratories. The pressure rating is listed on the valve body. In order to have the UL logo on the valve body, the ball valves must pass the UL test.

CSA. Another group that tests ball valves to verify they satisfy its criteria is the Canadian Standards Association. Despite the fact that this is a Canadian organization, it conducts tests that meet both Canadian and US criteria. Under its emblem, a "C" or "US" indicates which country's standards the ball valve has been tested to. If both are present, then that means the ball valve has been thoroughly tested in both countries.

FM. Factory Mutual Global, a US-based insurance firm, should also give its approval to the ball valve. To ensure that the valve fulfills their high standards, they adopt an engineering method.

4. Ball valve sizes

The size of the ball valve required is usually determined by the process engineering needs of your operation. The desired flow rate through the ball valve is typically the first factor to consider. The larger the bore, the better the flow rate, so start here, especially if you’re specifying a new assembly that will contain your ball valve.

You may be needed to indicate the size of the ball valve necessary based on the current fittings on-site in some cases. You will need either the Internal Diameter of the hose or the External Measurement of the Male Thread on the Fittings to determine the size of the valve you will need. Both of these dimensions should be close to the valve’s specified size. If neither of these is available, see if there are any site drawings or plans that may be inspected for product requirements.

5. Working pressure

The media pressure differential, which is the difference in PSI between the two sides of the ball valve, is another issue to consider. Applications with a large pressure differential are tougher on valve seals and have a shorter life expectancy. There are other important pressure ratings that should be considered before buying ball valves.

PN: Pressure Nominal Classes. The term "PN" stands for "pressure nominal." The number after PN denotes the valve's pressure class in bars, with 1 bar equaling 14.5038 PSI. Some manufacturers will just specify the pressure rating in PSI

PSI Rating. PSI (pounds per square inch) is basically a pressure measurement that is extensively used in the United States for equipment and instruments. A ball valve's pounds per square inch is a measurement of the pressure of the media flowing through it as it makes contact with a square inch of pipe or other objects.

CWP & WOG Ratings. The valve's maximum pressure rating at temperatures ranging from -20°F to 100°F is indicated by the cold working pressure (CWP). This is often used in conjunction with the valve's pressure rating. WOG (water, oil, and gas) is an older phrase that isn't as commonly used as it previously was. It simply indicates that the valve is designed to work with water, oil, or gas, but not flammable gasses

WSP rating. The greatest steam pressure that a ball valve can bear at its highest temperature rating is what is known as the working steam pressure (WSP). This could also be labeled as SWP, which now stands for steam working pressure.

6. Temperature

The most crucial requirements to precisely ascertain before picking a ball valve are the temperature and pressure of the flow of your media. The easiest method to locate a valve that meets your application requirements is to first understand these conditions. The temperature of the media and the environment around the valve should always be considered. The materials, valve design, and valve seal material will be determined by these temperatures.

7. Application

What exactly do you need the media to perform for you? Because ball valves come in a variety of forms, it’s critical to have a thorough understanding of the work at hand to ensure that the valve you select is the right fit for your application.

8. Annual Estimated cycles and Desired Lifespan

First, figure out how frequently you will be cycling the valve. You can determine the required lifespan of your ball valves once you have an annual estimate. Because the application and media will affect the longevity, most vendors will not guarantee the life expectancy of a ball valve and actuators. If a provider offers a guarantee or warranty, look into how they handle product faults in the event of an early failure.

9. Actuation

How you intend to operate your ball will affect the kind of ball valves you should go for. Handles or levers are used to operate manual ball valves and they are also ideal for applications that will be regulated on and off by a manual operator. Because these valves must be turned on and off, they are not well suited for high-cycle applications when done manually.

Pneumatic actuation on the other hand is ideal for applications with a lot of moving parts and those that need access to compressed air and/or the need for quick cycle times. Electric actuation is best for low-demand applications or applications that don’t have access to pressurized air

Hydraulic actuation is similar to pneumatic actuation, but it is more efficient. Because liquids cannot be squeezed, they provide higher torque. Hydraulic actuators are often more expensive than electric actuators. There are also more pneumatic ball alternatives like spring-return and double-acting valves.

Conclusion

Getting your valves from a reputable and dependable source will be your best bet for long-term success. There are numerous ball valve manufacturers, but very few can match SIO quality, diversity, and degree of customer satisfaction. SIO Valves has swiftly established a reputation for high-quality valves supplied on time and has established itself as a top valve provider globally. Feel free to contact us. We will assist you accordingly.