SIO metal seated ball valve is a type of ball valve with metal seats designed for critical applications. Our metal seated valve is generally used for isolation, but many are now being used for uni- and bi-directional controls.

The main advantage of a metal seated valve against a soft seated ball valve is its ability to withstand critical applications. The metal seats can endure high temperatures exceeding 1,000° F, hydraulic shock, extreme flashing, and abrasive process fluid. They are also suitable for high-erosion and corrosion services. They are widely used in the oil and gas industries, power generation, petrochemicals, mining, and pulp and paper industries.

Another advantage of a metal seated ball valve is it can be tougher through special coatings. The application of these coatings will make the seat rings and ball hard-faced on sealing areas. Excellent examples of special coatings include tungsten carbide, chromium carbide, hard facing, and electrolysis nickel plating.

A significant difference between soft seated valves and metal seated valves is the material used for the seats. Soft seated valves are usually made from thermoplastic materials like PTFE, while metal seat designs are made from durable metal like stainless steel and carbon steel.

Soft seated valves are suitable for applications where chemical compatibility and tight sealing are crucial. Meanwhile, metal seated valves are capable of maintaining a tight shutoff even in extreme conditions.

Even though it costs more than a soft seated valve, the efficiency, safety, and longevity of a metal seated ball valve will pay off. Therefore, it is the best and economical option for crucial applications.

How Does a Metal Seated Ball Valve Work

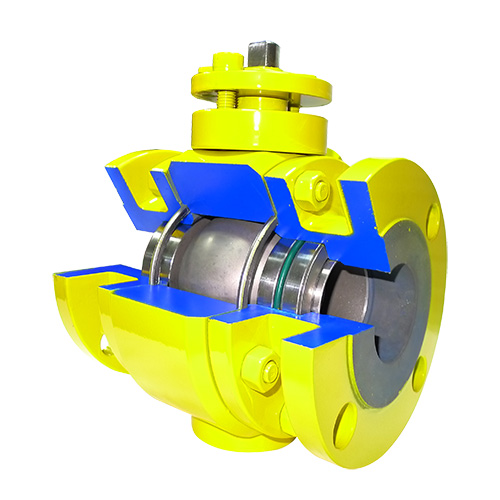

SIO metal seated ball valves combine a metal-to-metal seal between the ball and seats of the valve assembly. This gives them the ability to withstand corrosives, abrasives, and high-pressure/ high-temperature applications. They are compliant with ANSI Class IV leakage standards, which only permits less than 0.01% leakage of the valve’s full open capacity.

The seat design of our metal seated ball valve can either be floating or trunnion mounted. SIO floating metal seated ball valves provide effective bi-directional sealing and cavity relief. The precise connection between the spring-loaded seat rings increases the sealing capacity over high pressures. They also produce a mechanical cavity relief to the pressurized side of the ball valve for both flow directions.

The spring-loaded seats located in the valve body ensures tight sealing and low operational torques in high- or low-pressure applications. In case of a rapid buildup of pressure in the cavity, the spring-loaded seats will relieve the excess pressure to the pressurized side of the valve.

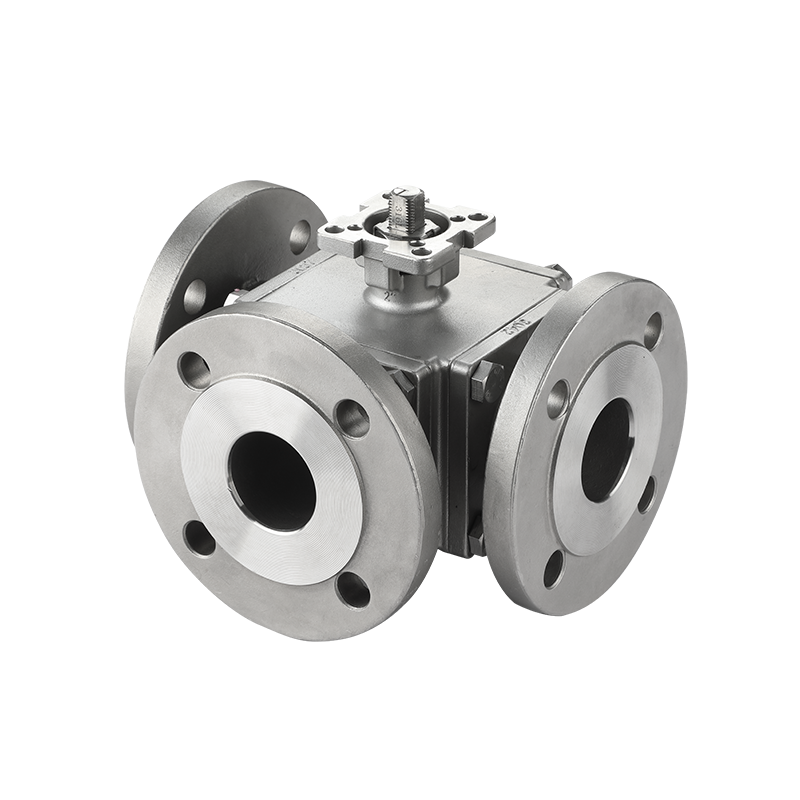

SIO trunnion mounted metal seated ball valve is equipped with a double block and bleed (DBB) mechanism. It consists of two independent seat rings that provide bi-directional sealing of the valve against a range of different pressures.