What Does WOG Mean on a Valve

Share:

When you consider the nature of valves used in heavy industries like oil refineries, then you will understand the need for them to be solid due to safety concerns. The pressures and the temperatures that are part of the entire process can be too much for people around. For this reason, the valves used usually come with distinct markings made up of codes and abbreviations that help users correctly identify the product they need for a specific function.

Among the many markings that exist in the market, there is one called WOG, which is an abbreviation for Water, Oil Gas. We are going to explore what WOG entails, how it affects functionality and why it is important to valve manufacturers and suppliers. If you have an interest in valves used in refineries or other heavy industries, then stick around to the end.

Table of Contents

What is WOG?

Source: www.qrfs.com

The WOG rating basically stands for Water, Oil, and Gas, and it represents the maximum pressure per square inch that the valve in question can handle. Every valve is given a WOG rating, and caution should be exercised to ensure that that rating is not exceeded at all costs.

When it comes to the designation of the ratings, each material is granted value depending on the materials used in their construction. Stronger materials are given a higher WOG rating, while the weaker ones are given a lower one. In the event that the values indicated are exceeded, the valve will run the risk of not working properly, and this could lead to permanent damage, which may in turn cause accidents.

Importance of Valve Markings

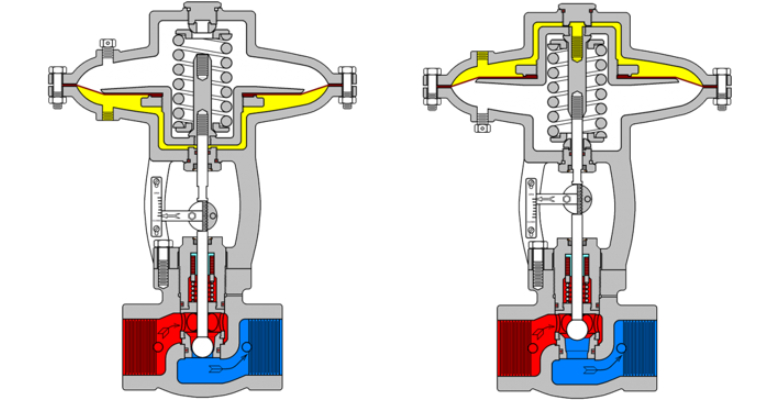

Source: GeminiValve

WOG, like any other valve markings, serve specific functions, with the biggest one being providing ample information in regards to the nature of the valve in question and what it has been designed for. Besides all that, the following are some of the other features that any type of valve marking will unveil for you.

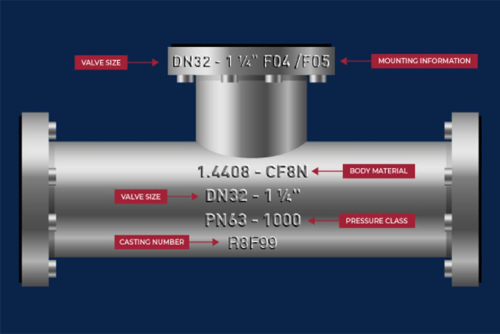

Valve Size: The marking will tell you everything you need to know about the size of the valve. This is indicated in the form of inches and is usually denoted by a simple “DN”. This is an abbreviation for Diameter Nominal, and the number that follows that prefix is the size of the pipe in inches or millimeters.

Mounting Information: Every valve has to go into something else where it works as the door that opens and closes to allow materials to pass through. For the valve to fit, there has to be compatibility, and the easiest way to figure this out is by reading the markings. WOG markings, among others, also indicate the mounting information that is ISO standardized. Before mounting the valve to the actuator, check out the information on the valve.

Body Material: The WOG marking also indicates the nature of the atrial used to make the valve. For instance, if you see a marking like CFM8, then that is an indication that the cast used in the construction of the valve is cast 316 stainless steel. Materials do matter a lot, and it would serve your interest to know what you are buying.

Pressure Class: When you see the initials “PN” on a valve, that refers to Pressure Nominal. Any number that follows these initials indicates the pressure class that the valves are designed for. A single-digit 1 is equivalent to a pressure rating of 14.5 PSI. This tells you all that you need to know about what that valve can handle.

Casting Number: This is a number that is created to track the materials and the batches used in the construction of the valve. Sometimes it can only be one, and at times, there can be several types of materials depending on the intended work of the valve.

Lead Content: Lead is a contaminant that is still being used in the manufacturer of many items around the world, valves included. To tell whether a valve has lead or not, simply look at the WOG marking. If you see the initials “LF” then that means that the valve in question is lead-free.

Manufacturer Information: Knowing who made the valve is another piece of important information that can tell the consumer the quality of the valve they are dealing with. It is standard that the name of the manufacturer is engraved on the valve.

Model Number: This is another important piece of information that points more to the identity of the valve manufacturer than the functionalities of the valve. It may not be necessary, but having it engraved on the valve does provide extra information that may come in handy at some point.

Who Decides the WOG Markings?

WOG markings, and any other type of marking being used in the manufacturing world, are not random. They are a set of rules that guide them, and these rules are set and arbitrated over by a number of global organizations that bring together manufacturers and suppliers of valves. These bodies include the following.

Uniform Plumbing Code

Source: www.iapmo.org

Abbreviated as UPC, the Uniform Plumbing Code is a certification mark that indicates the ball valve in question is in line with the performance of the product standards and those that are set by the International Plumbing and Mechanical Officials (IAPMO). UPC is an American standard, and it governs the installation and inspection of plumbing systems as a route to promoting public health, welfare, and safety. This also creates a conducive environment for top valve manufacturers to come up with new innovations.

American National Standards Institute

Source: www.ansi.org

ANSI is one of the most notable standards in the world that governs the manufacturing, supply, and installation of ball valves, and their markings are found in almost all of the best valves you will ever come across. The American National Standards Institute ensures that the products being made are consistent with what they are designed for without taking any shortcuts.

Underwriters Laboratories

Source: www.ul.com

Underwriters Laboratories is another well-known safety standard enforcer that conducts a number of tests on a wide range of products, including most valves that are used in most refineries and other related industries. They usually stamp their logos on the valves they have inspected, and that is a sign that the product in question is safe for use. UL draws its strength from its reliance on science in its research and testing methods to increase the accuracy so that the test results are not biased in any way.

American Society of Mechanical Engineers

Source: www.asme.org

ASME is a standard that is based on science, art and the practice of multidisciplinary engineering around the globe. This conglomeration of engineers has come up with specific standards that govern how some valves are designed and created with the aim of promoting safety and functionality. The American Society of Mechanical Engineers has over 90,000 members globally, and that gives the body a solid say in how things are run.

Conclusion

WOG ratings, and any other ratings used for valves, are an important part of the whole process. It displays all the information needed to know exactly what and where the valve will be used for. If you are planning to get valves for any large or small-scale operations but are lost on where to start, then check out our website at any time of the day and have all your questions addressed fully.